Locking mechanism, connecting mechanism, connecting assembly and working method of locking mechanism

A technology of locking mechanism and connecting mechanism, which is applied in the layout, transportation and packaging of pedals or ladders, and vehicle components, etc., can solve the problems of increased weight, large vibration inertia, and difficult disassembly and assembly of automatic stepping devices, and can be widely popularized and applied. Meaning, the realization process is simple, the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

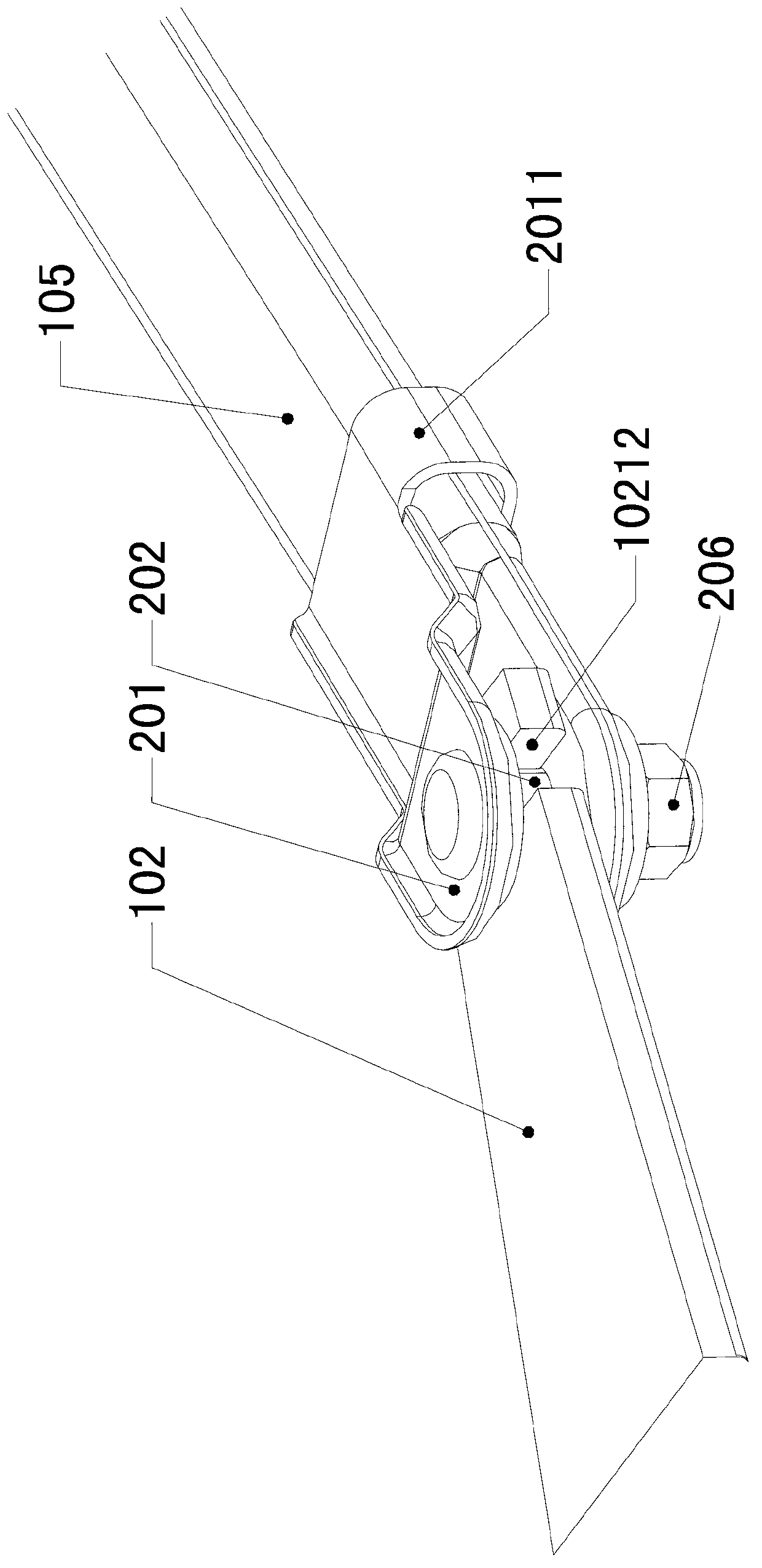

[0045] figure 2 A schematic structural view of the locking mechanism 103 according to the present invention is shown, as figure 2 As shown, the locking mechanism 103 is used to connect the first connection part 102 and the second connection part, and the locking mechanism 103 includes a special-shaped shaft 202 , a first washer 203 and a second washer 204 . specifically:

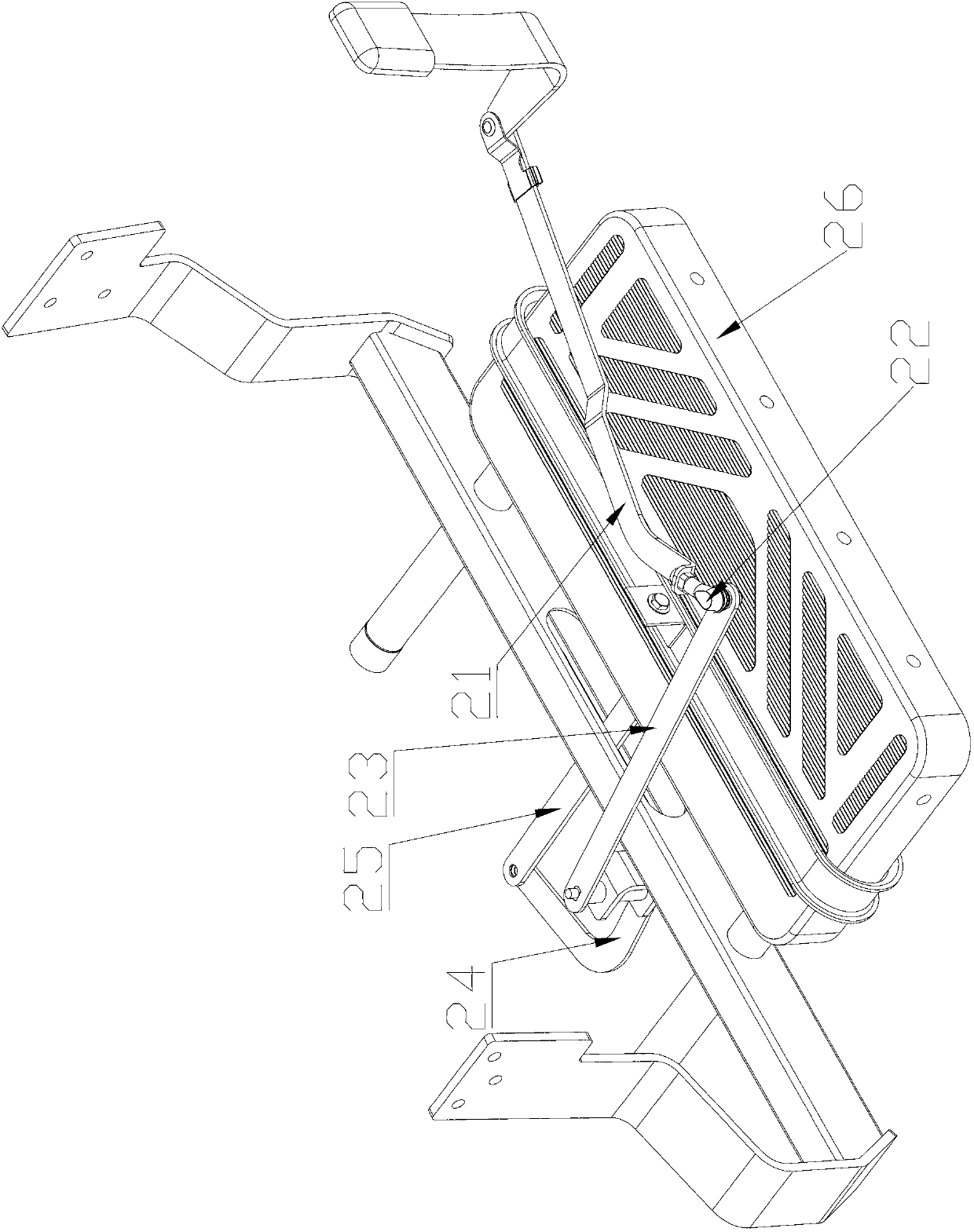

[0046] Such as Figure 10 with 11 As shown, the second connecting part is a four-bar linkage structure including a first link 105, a second link 107, a third link 109 and a fourth link 108, and the head end of the first link 105 is the first link 105. The head ends of the two connecting parts, and the connecting rods 105, 107, 109, 108 are rotatably connected between each other through pin shafts.

[0047] refer to Figure 3 to Figure 5 , the profiled shaft 202 is sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com