Novel automatic production system for electromagnetic single-spiral turbine plasticizer

A production system and single-screw technology, applied in the field of new electromagnetic single-screw turbo plasticizer automatic production system, can solve the problems of inability to completely clean the plasticizing pipe, unstable product quality, difficult cleaning, etc., to improve production efficiency and Production quality, reduce machine maintenance and repair, reduce the effect of reducing product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other purposes, features and advantages of the present invention more obvious and understandable, the following preferred embodiments are given in detail below, together with the drawings in the description. These embodiments are for illustration and not in any form. Limitations of the invention:

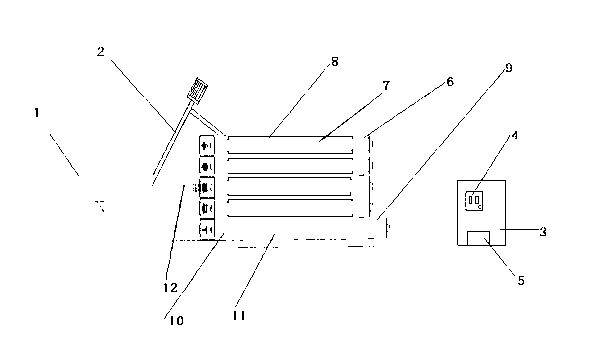

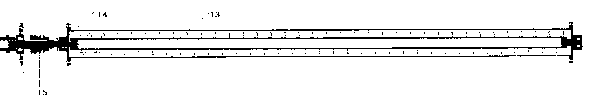

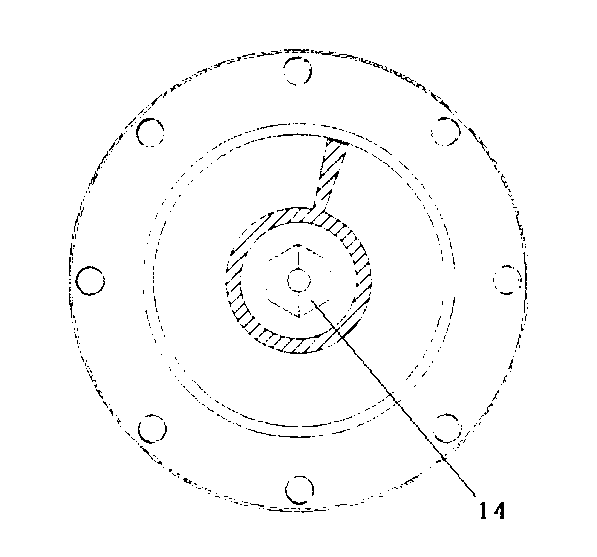

[0022] A novel electromagnetic single-screw turbo plasticizer automatic production system, comprising a stirring device 1, a feeding device 2, a plasticizing device, a cooling device and a control device 3, the outlet of the stirring device 1 is connected to the feeding device The feed port of 2 is connected, the discharge port of the feeding device 2 is connected with the feed port of the plasticizing device, and the discharge port of the plasticizing device is connected with the feed port of the cooling device , the discharge port of the cooling device is connected to the next process, the control device 3 is provided with a computer control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com