Mechanical rock breaking test platform confining pressure device

A test platform and rock-breaking technology, applied in the field of rock test machinery, can solve the problem of inability to simulate the state of rock on the face of the rock under in-situ stress, etc., and achieve the effect of simple and feasible device design and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

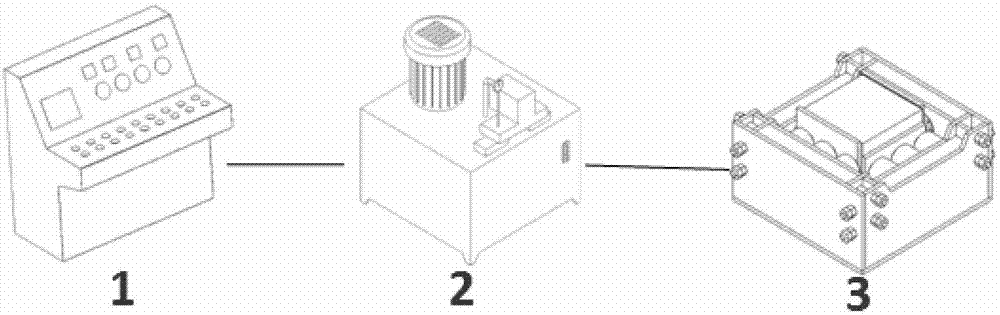

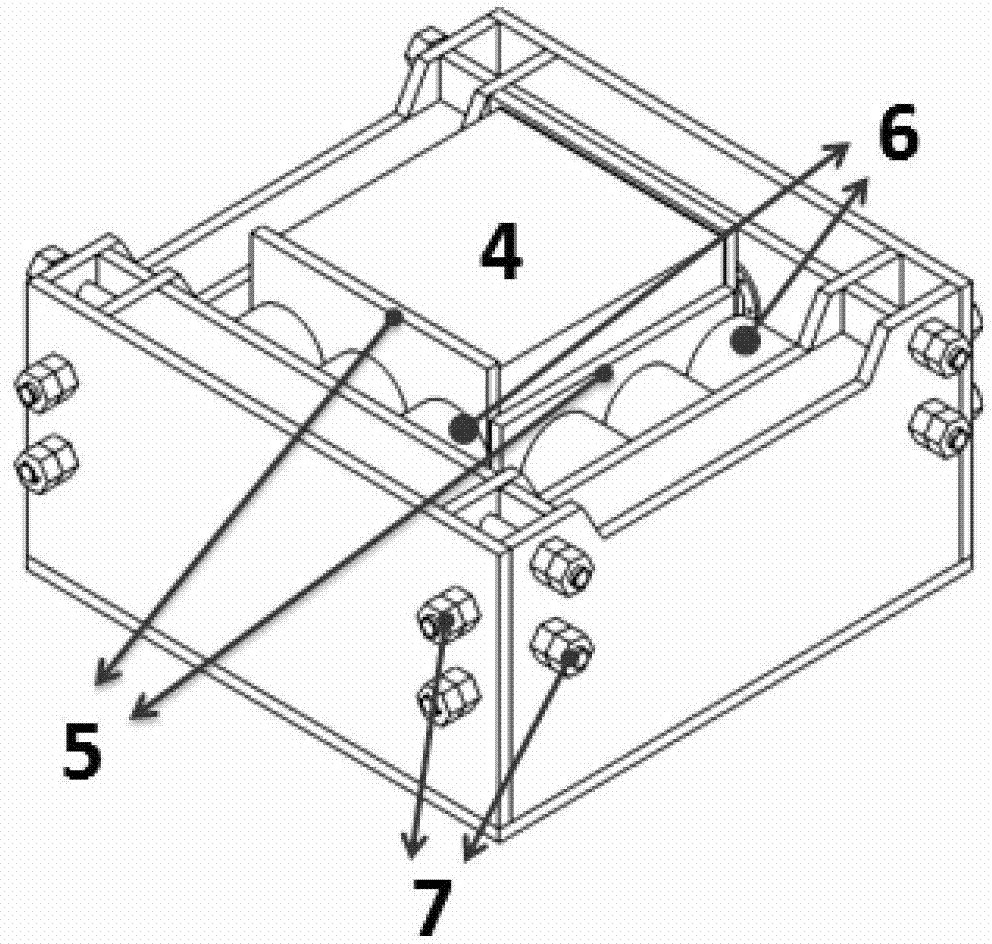

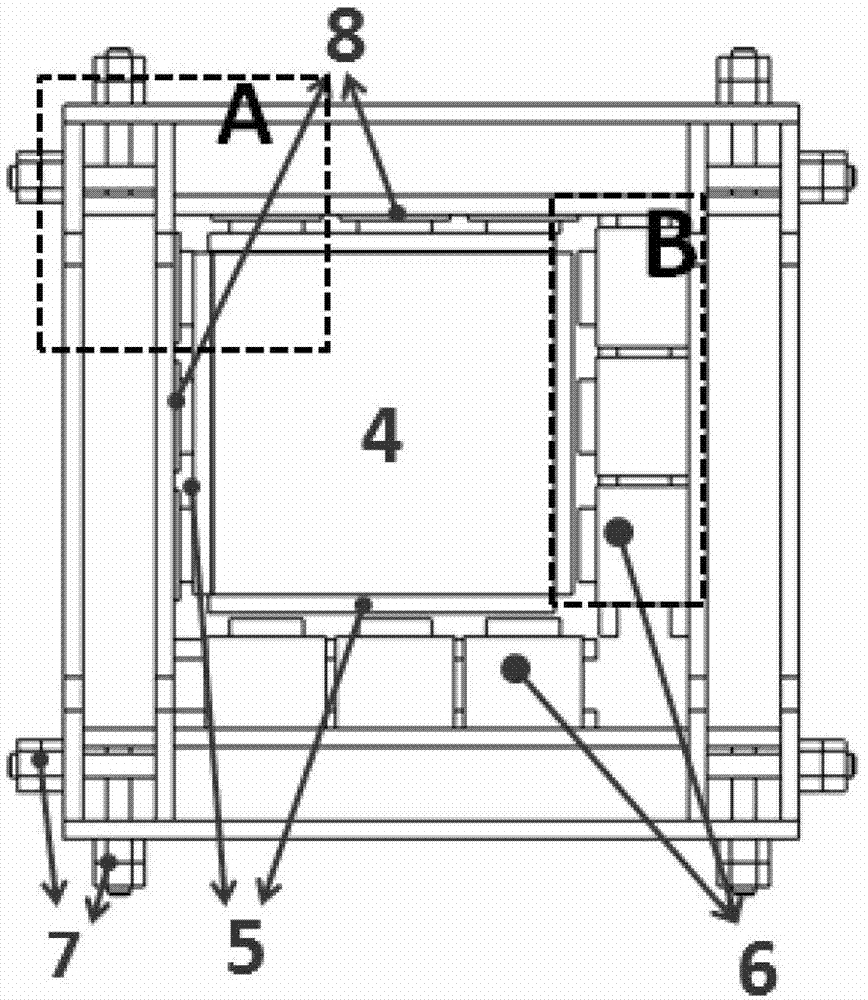

[0016] As shown in the figure, in the confining pressure device of the mechanical rock-breaking test platform in the present invention: the electric control system 1 is connected to the hydraulic station 2, and the hydraulic station 2 is connected to the hydraulic cylinder 6 placed in the sample box 3 through a hydraulic hose. The electric control system 1 controls the hydraulic cylinder 6 to apply an adjustable confining pressure to the sample 4;

[0017] It is stipulated that the side away from the sample 4 is the outer side, and the side close to the sample 4 is the inner side. Three hydraulic cylinders 6 are placed on the cylinder support 10 in groups of three. There are two groups in total. Any adjacent two walls in the sample box 3 are arranged close to each other. Each group of hydraulic cylinders 6 can exert a maximum pressure of 20 MPa on the sample....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com