Battery terminal with current sensor

A current sensor and battery terminal technology, which is applied to small-sized batteries/battery packs, battery pack parts, battery boxes/coats, etc., can solve the problems of rapid battery consumption, prevent appearance deterioration, have sufficient strength, and eliminate influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

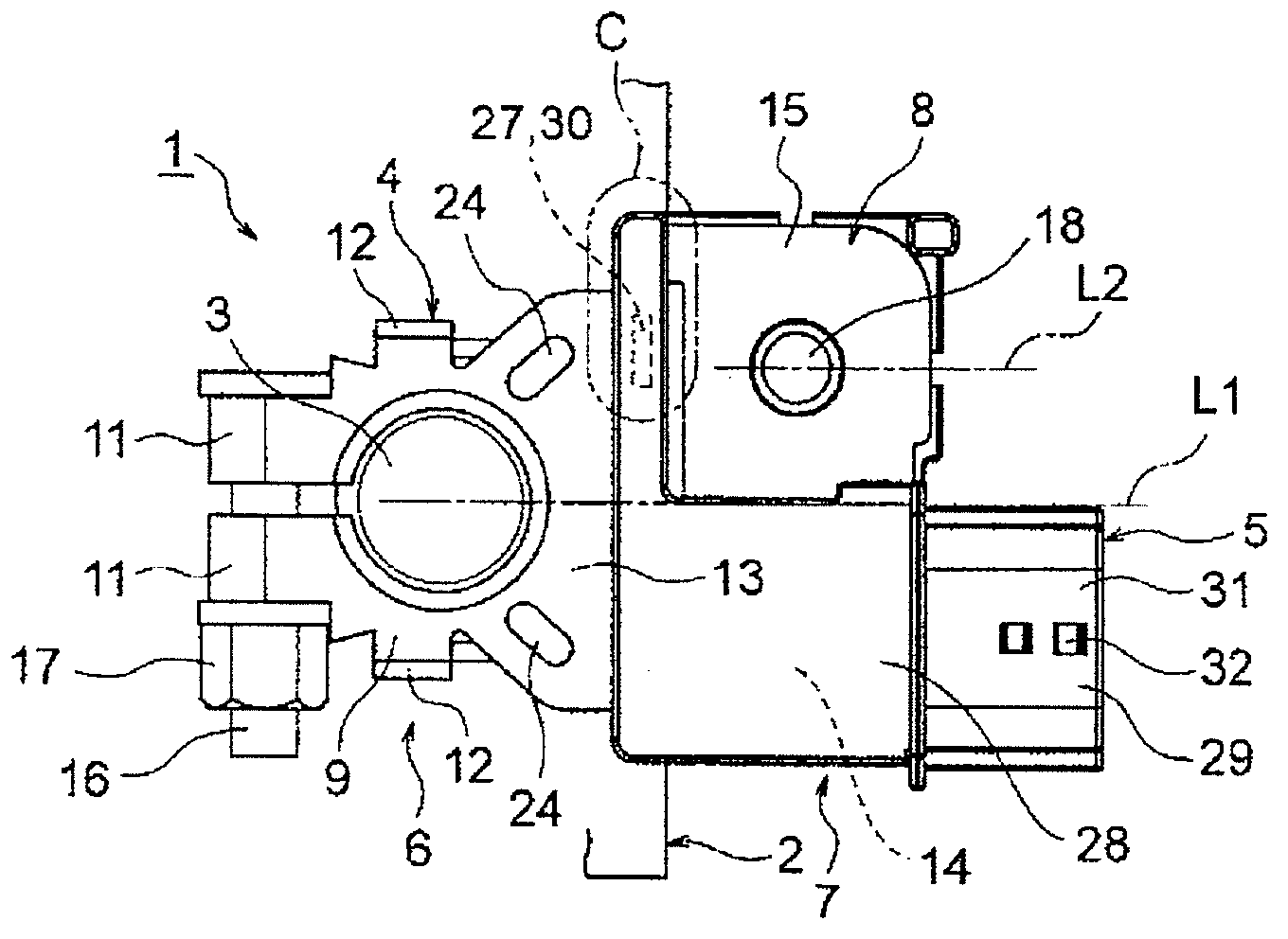

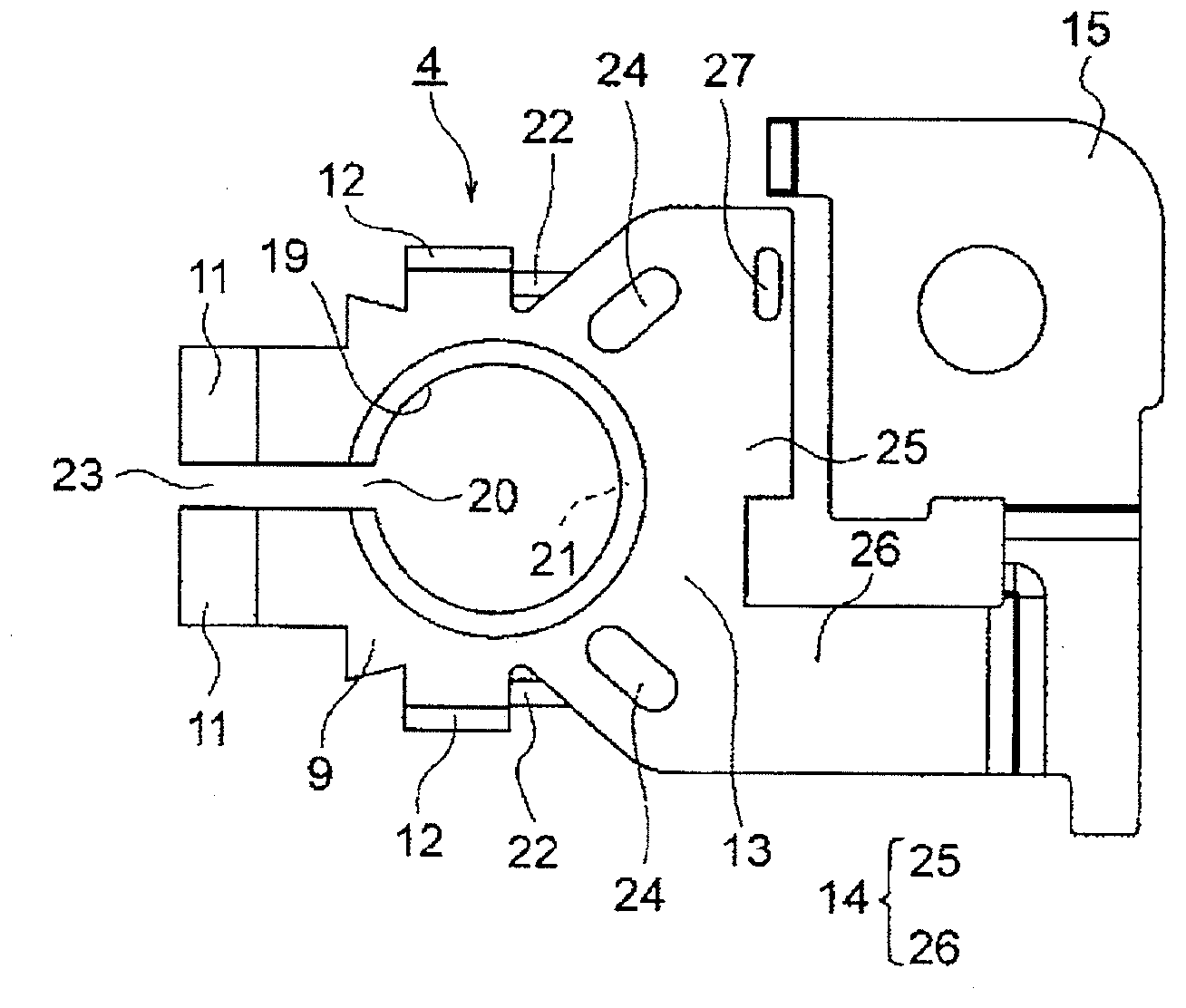

[0049] Hereinafter, a first embodiment will be described with reference to the drawings. Figure 1A to Figure 4B are a plan view, a bottom view, and a perspective view of a battery terminal with a current sensor and a battery terminal portion constituting the battery terminal with a current sensor according to a first embodiment of the present invention. Figure 7 is a plan view of another battery terminal portion according to another illustrative embodiment.

[0050] FIG. 1 shows a battery terminal 1 with a current sensor. A battery terminal 1 with a current sensor has: a battery terminal portion 4 connected to a battery post 3 of a battery 2 to be mounted on a mobile body such as an automobile; and a current sensor 5 passed through a resin The molding is integrated with the battery terminal part 4, but the configuration of the battery terminal 1 with a current sensor is not limited thereto.

[0051] The battery terminal 1 with current sensor has such a structure that the p...

no. 2 example

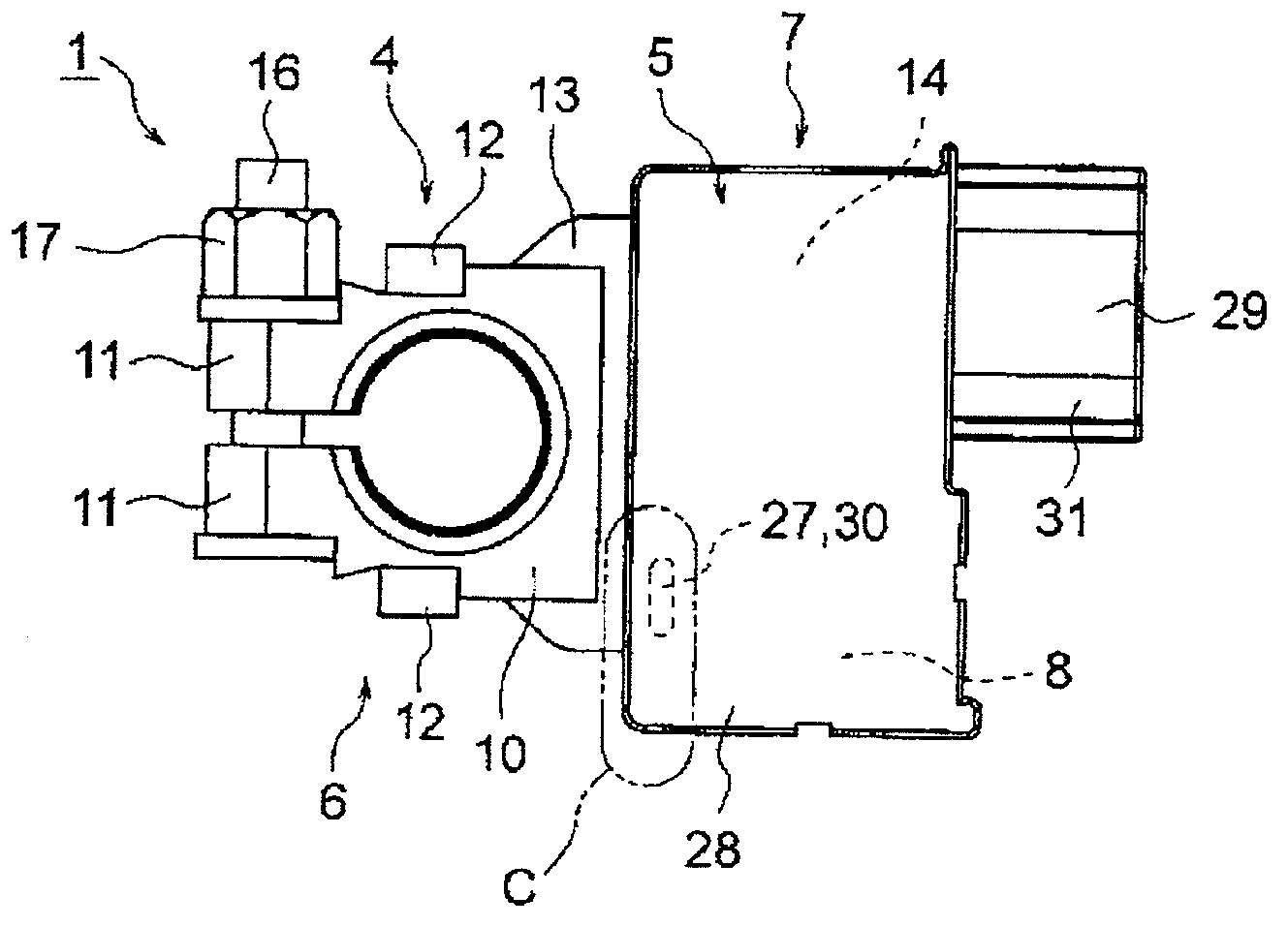

[0083] Hereinafter, a second embodiment will be described with reference to the drawings. Figure 5 is a perspective view of a battery terminal with a current sensor according to a second embodiment of the present invention. in addition, Figure 6A yes Figure 5 A plan view of the battery terminals with current sensors, and Figure 6B yes Figure 5 The plan view of the battery terminal part.

[0084] Figure 5 , Figure 6A with Figure 6B A battery terminal 41 with a current sensor according to a second embodiment is shown. The battery terminal with current sensor 41 has a battery terminal portion 42 connected to the battery post 3 of the battery 2 (see FIG. 1 ), and a current sensor 43 integrated with the battery terminal portion 42 by resin molding.

[0085] The battery terminal part 41 with a current sensor has: the pole part 44 of the battery terminal part 42, and the pole part 44 is a part connected to the battery pole 3 (see FIG. 1); the sensor part 45, the sensor pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com