Fusing tube

A fuse tube and tube body technology, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of lower success rate of drop-type fuse tubes, waste of maintenance time, difficulty of maintenance personnel, etc., and achieve simple structure and increased reliability , Fuse safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

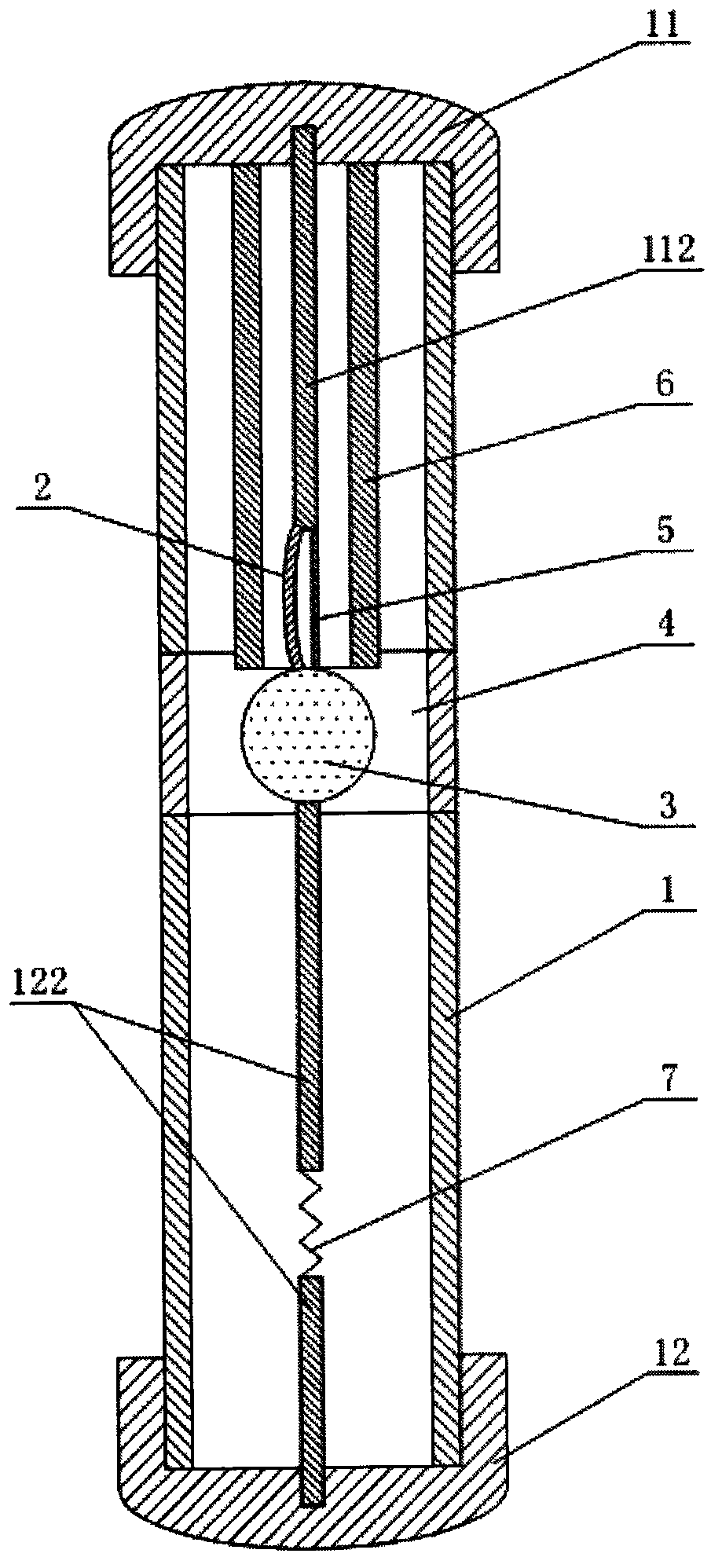

[0011] refer to figure 1 One embodiment of the fuse tube of the present invention includes a tube body 1, the upper end of the tube body 1 is sealed with a metal upper cover 11, the lower end of the tube body 1 is sealed with a metal lower cover 12, and the tube body 1 is provided with a fuse 2 , the fuse 2 is electrically connected to the upper cover 11 and the lower cover 12 through the upper wire 112 and the lower wire 122 respectively, and the connection between the fuse 2 and the lower wire 122 is provided with a fluorescent ball 3, and the tube body corresponding to the fluorescent ball 3 1 wall is provided with annular transparent window 4. Among them, the fluorescent ball 3 uses a metal sphere with a certain weight, and the outside is coated with fluorescent materials and colored pigments, etc., so that it can be observed at a distance. When the fuse 2 was not yet blown, the fluorescent ball 3 was affected by the upward pulling force of the fuse, the gravity of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com