Polysilicon granule preparation system and preparation method

A preparation system, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of uneven particle size of polysilicon particles, large loss rate of polysilicon fine powder, low utilization rate of polysilicon seed crystals, etc., to achieve Improve the utilization rate of raw materials, high production efficiency and output, and inhibit the effect of adhesion and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

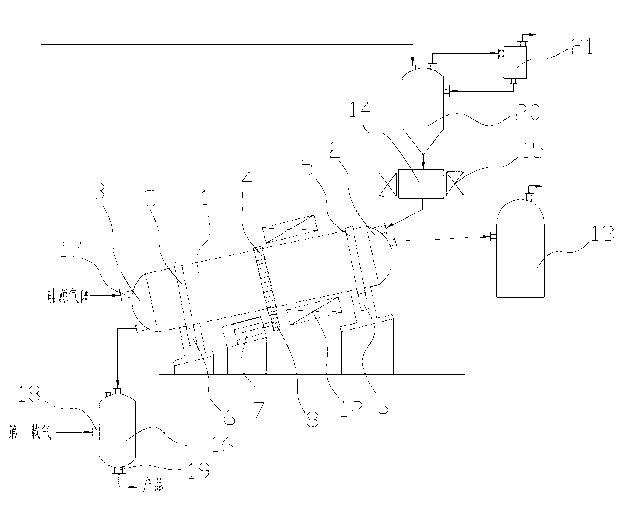

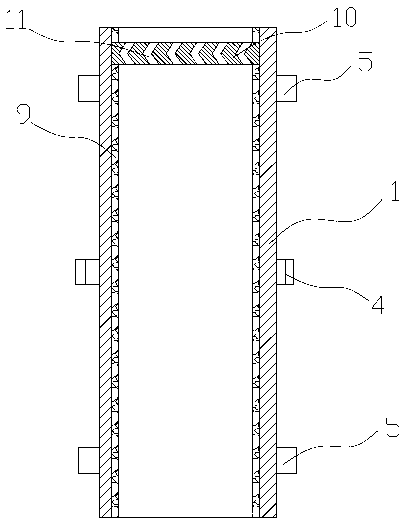

[0043] Such as figure 1 In the shown embodiment, a polysilicon granule preparation system includes a rotary fluidized bed, a primary cyclone separator 16, a secondary cyclone separator 20, a carrier gas filter 21, a material preheating storage tank 14 and an exhaust buffer Tank 13, the rotary fluidized bed includes a reaction cylinder 1, an upper head 2 and a lower head 3, the middle of the reaction cylinder 1 is covered with a ring gear 4, and the reaction cylinder 1 on both sides of the ring gear 4 is respectively covered with a The tire belt 5, the reaction cylinder body 1 is obliquely installed on the supporting wheel 6 corresponding to the position of the tire belt 5 through the tire belt 5, and the upper head 1 and the lower head head 2 are respectively fixed on the reaction cylinder body 1 by means of magnetic sealing. The upper and lower ends are fixed on the ground through brackets, and the entire rotary fluidized bed is supported by the cooperation of the supporting ...

Embodiment 2

[0051]Compared with Example 1, the polysilicon particle preparation system of this embodiment differs in that the inclination angle of the rotary fluidized bed is 30°, the thickness of the inner liner 9 is 2 mm, and the openings on the surface of the baffle 10 are rate of 25%, the cross-section of the baffle baffle 10 is a circle with a diameter of 18 cm, the turning angle of the baffle 11 is 100°, and the first heating device 12 and the second heating device 15 are resistors. All the other heating devices are identical to those in Example 1, so they will not be repeated here.

[0052] A method for preparing polysilicon particles, comprising the steps of:

[0053] (1) The polysilicon seed crystals with a particle size of 10-100 μm in the material preheating storage tank 14 are preheated to a surface temperature of 1200° C. by the second heating device 15 .

[0054] (2) Put the preheated polysilicon seed crystal into the rotary fluidized bed, the rotating speed of the reaction...

Embodiment 3

[0059] Compared with Example 1, the polysilicon particle preparation system of this embodiment differs in that the inclination angle of the rotary fluidized bed is 40°, the thickness of the inner liner 9 is 3 mm, and the openings on the surface of the baffle 10 are The ratio is 30%, the cross-section of the baffle channel 11 of the baffle plate 10 is a circle with a diameter of 20 cm, the turning angle of the baffle channel 11 is 60°, and the first heating device 12 and the second heating device 15 are both inductive All the other heating devices are identical to those in Example 1, so they will not be repeated here.

[0060] A method for preparing polysilicon particles, comprising the steps of:

[0061] (1) The polysilicon seed crystals with a particle size of 10-100 μm in the material preheating storage tank 14 are preheated to a surface temperature of 1300° C. by the second heating device 15 .

[0062] (2) Put the preheated polysilicon seed crystal into the rotary flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com