Printing and dyeing mechanism of a printing machine

A technology for printing presses and embossing rollers, which is used in printing presses, general parts of printing machinery, printing, etc., can solve the problems of difficult to clean ink, low ink utilization rate, difficult to clean, etc. The impact of workers' physical and mental health, the improvement of ink utilization rate, and the effect of printing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

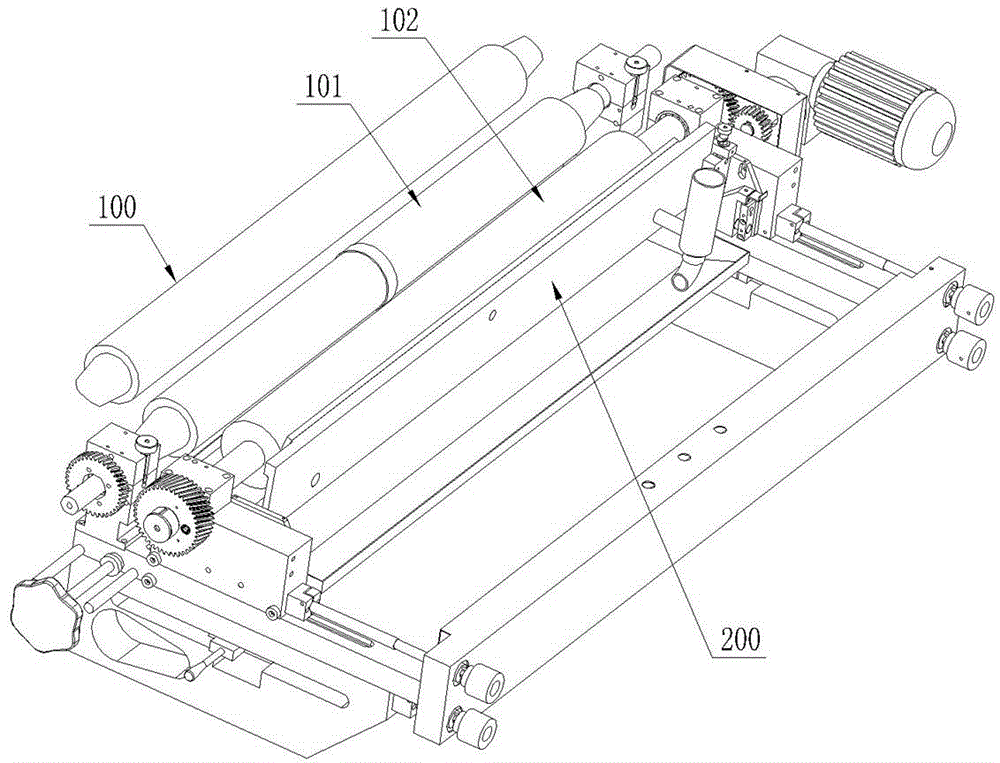

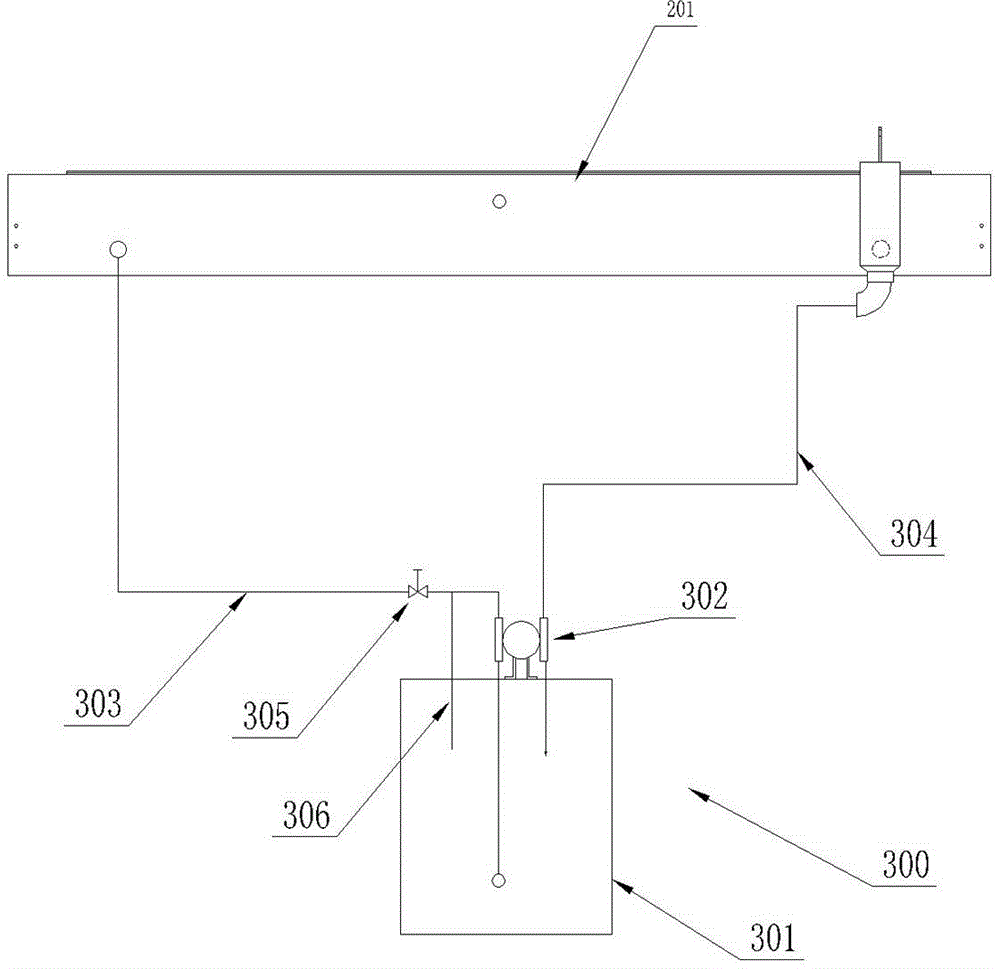

[0027] The present invention is a printing and dyeing mechanism of a printing machine, please refer to figure 1 and figure 2 , the printing and dyeing mechanism of the printing machine includes an embossing roller 100 , a printing plate roller 101 , an anilox roller 102 , an ink storage bar 200 and an ink delivery device 300 .

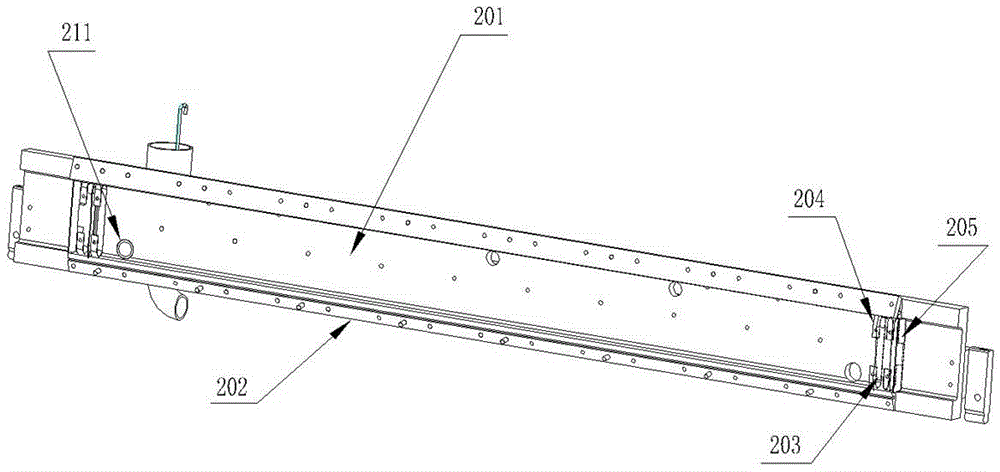

[0028] as the first image 3 and Figure 5 As shown, the ink storage bar 200 is located on the right side of the anilox roller 102. The ink storage bar 200 includes two flanges 207 up and down. The two flanges 207 form a groove 201 facing the anilox roller 102. The upper surfaces of the two flanges 207 are There is an acute angle slope with the ink storage bar, the upper surface of the flange 207 is fixed with a scraper through the clamp block 206, and a sealing member is arranged in the ink storage bar groove 201 at both ends of the scraper 202, and the sealing member includes a soft Sealing block 203, the outer surface of the sealing block 203 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com