Combined hydraulic drawbench jaw plate

A technology of machine pliers and jaw plates, which is applied to the field of jaw plates for hydraulic cold drawing machines, can solve the problems of low material utilization rate, high production cost, single jaw plate, etc., saving financial resources and manpower, saving replacement time, The effect of material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

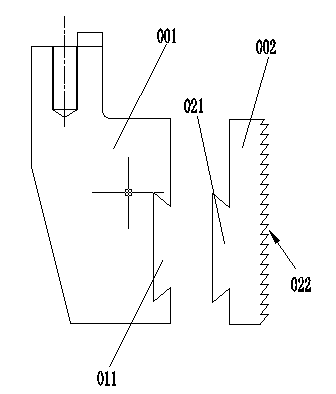

[0011] A combined hydraulic puller jaw plate, comprising a clamping part 001 and a jaw working part 002 snapped into the clamping part 001. The clamping part 001 is a square base body with a width of 140 mm, and one side wall of the base body There is a dovetail notch 011 penetrating transversely in the center, a dovetail protrusion 021 matching with the dovetail notch 011 is provided at one end of the jaw working part 002 , and a serrated 022 is provided on the other end surface. The jaw working part 002 is 45# steel after carburizing and quenching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com