A method for protecting a synchronous machine against damage caused by pole slipping

A magnetic pole sliding and synchronous machine technology, applied in the direction of controlling generators, general control systems, instruments, etc., can solve problems such as unrealizable, achieve the effect of simplifying detection, simple measurement system, and avoiding the measurement of load angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

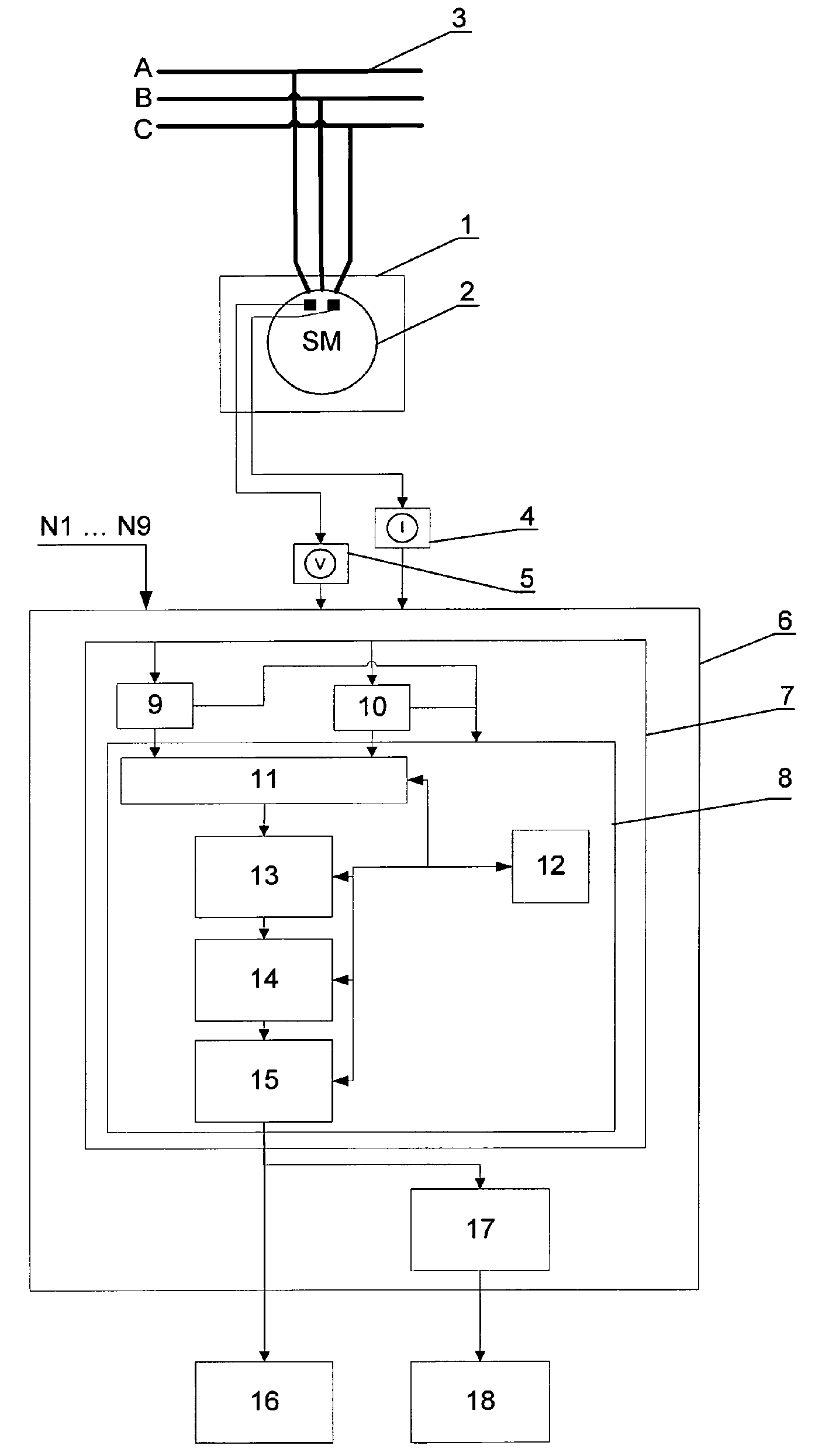

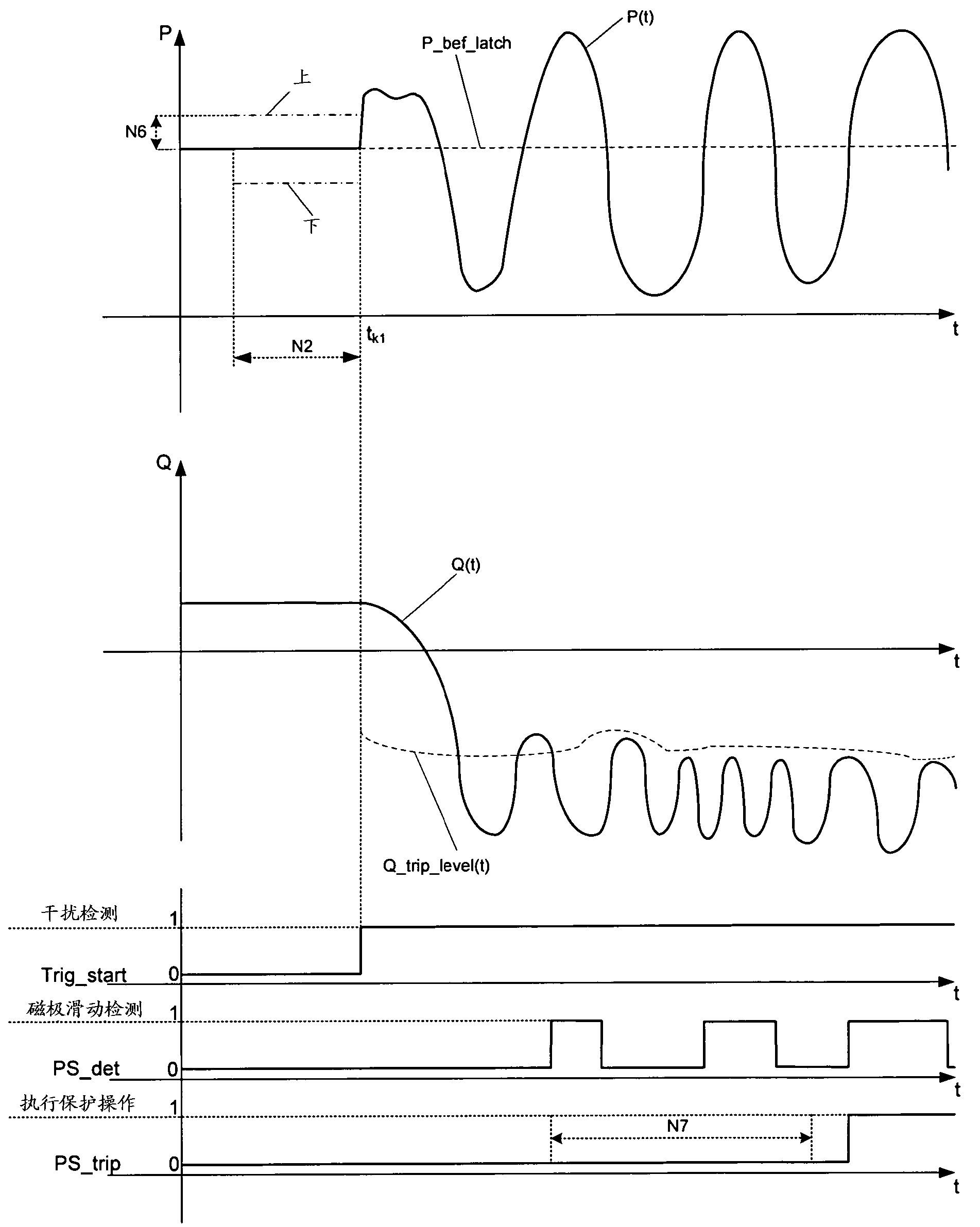

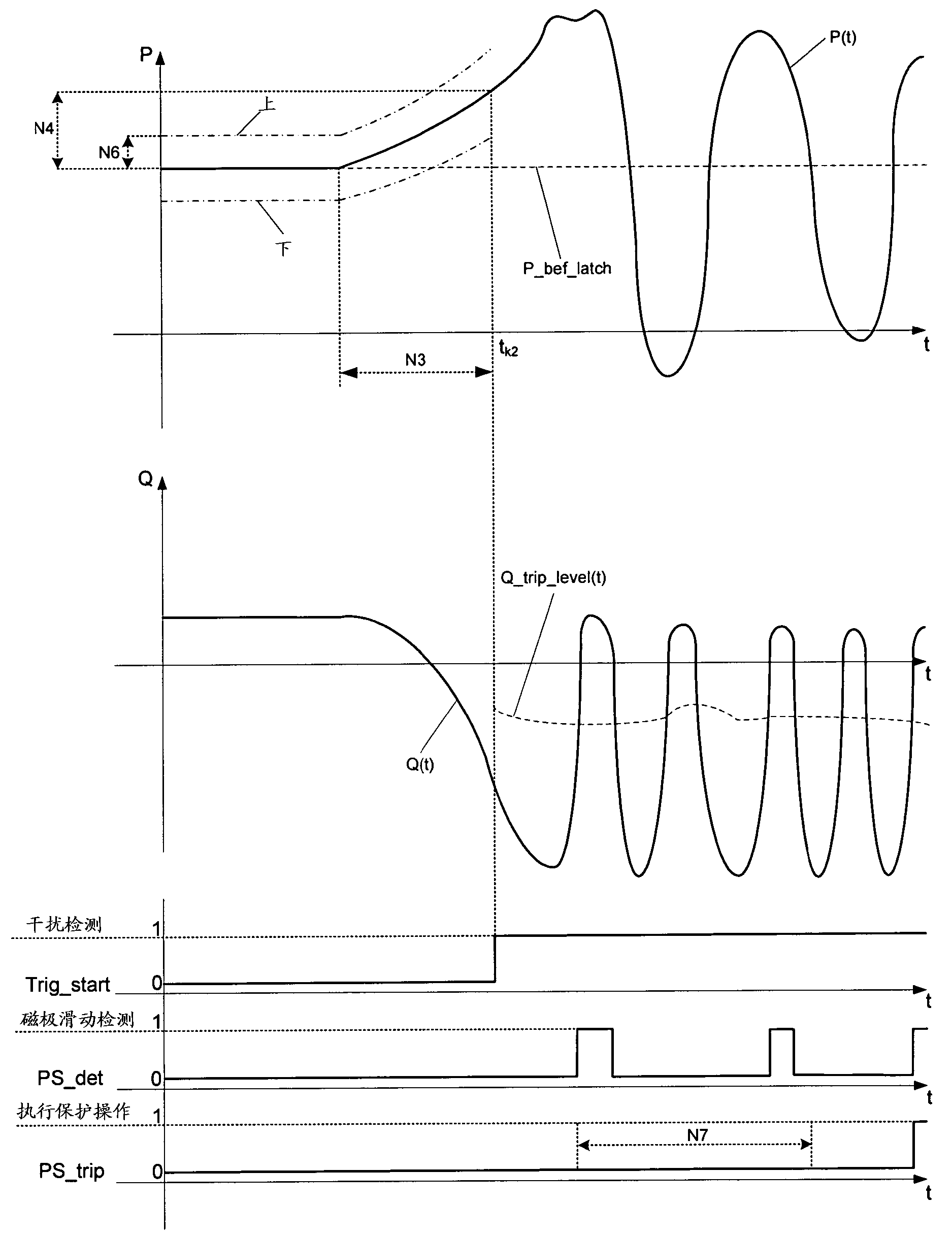

[0037] The inventive method is based on the measurement of voltage and current of a synchronous machine, which is part of the generating / driving unit and which is tested under load, and on the use of synchronous machine active and reactive power waveforms for detecting pole-slip phenomena. The power generation or drive unit 1 tested comprises a synchronous machine 2 in the form of a motor or synchronous generator, which is connected to a three-phase power grid 3, with subsequent phases indicated by symbols A, B and C. The synchronous machine 2 (which is part of the power generation / drive unit 1 ) is provided with at least one sensor 4 for measuring the current of the three phases A, B and C and at least one sensor 4 for measuring the voltage of the three phases A, B and C sensor 5. The sensors 4 and 5 are connected to a computer measuring device 6 comprising a processor 7 with a memory 8 and a number of functional modules, eg for reading in and storing the synchroniser (which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com