Built-in clutch and its combined motor with this clutch

A clutch, built-in technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of unreasonable force structure, troublesome motor assembly, stuck, etc., to improve the torque transmission per unit space, avoid The effect of clutch failure and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

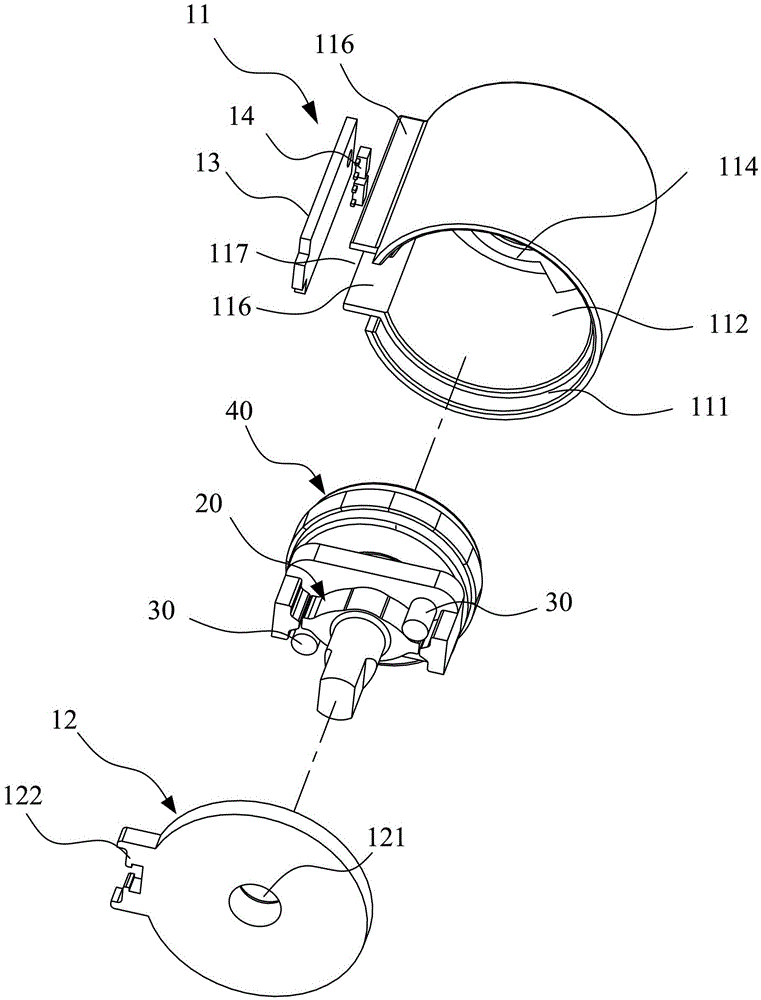

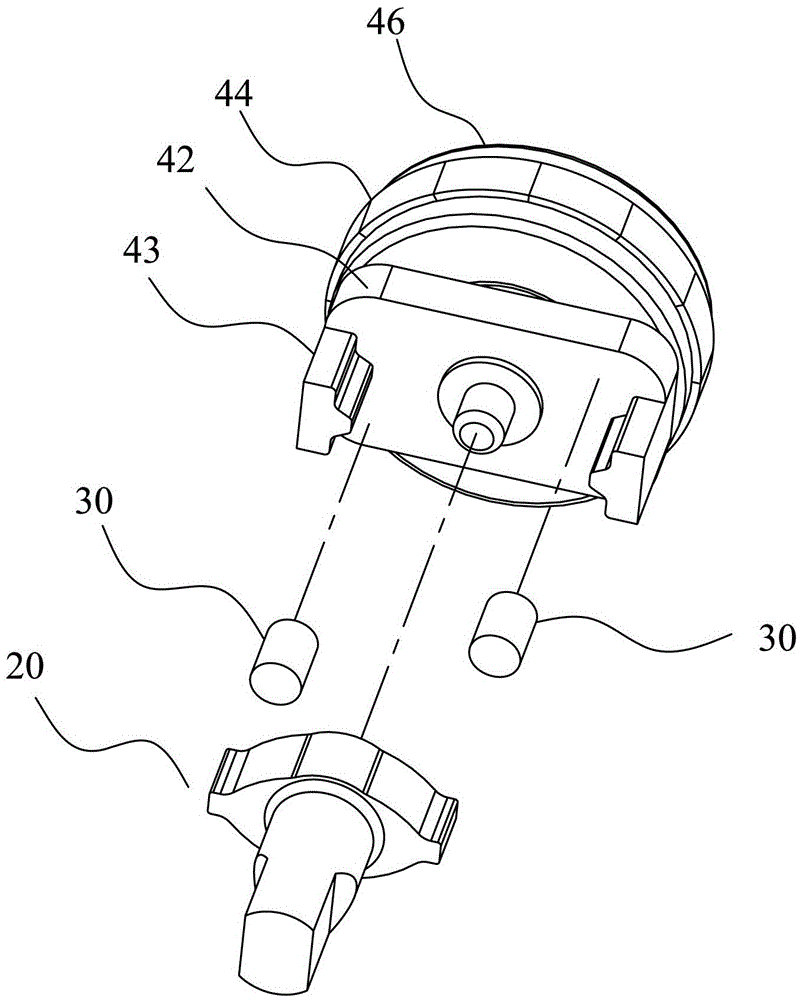

[0073] Please refer to Figure 1 to Figure 14 As shown, it shows the specific structure of the first embodiment of the present invention, the clutch includes a stationary housing 10 and a clutch assembly that rotates in the housing 10, the clutch assembly includes a driving member 20, a slide block 30, Driven part 40, wherein the driving part 20 is used as a driving wheel, a motor is connected to the reduction box and then connected to the driving part 20, the driven part 40 is used as a driven wheel, the driving part 20 is concentrically connected with the driven part 40, the driving part 20 drives the driven member 40 to rotate through the slide block 30 rotatably adsorbed on the driving member 20. When the clutch is “closed”, the driving member 20, the slide block 30 and the driven member 40 rotate synchronously.

[0074] Among them, such as figure 1 and figure 2 As shown, the housing 10 is cylindrical and includes a housing main body 11 and a cover body 12. The housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com