Multi-stage heat pump compressor

A compressor, multi-stage technology, applied in the field of compressors, can solve the problems of the compressor being bulky, noisy, and the uneven force on the connecting shaft 30, and achieve the effect of good service life and operational stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The detailed description and technical content of the present invention will be described as follows with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

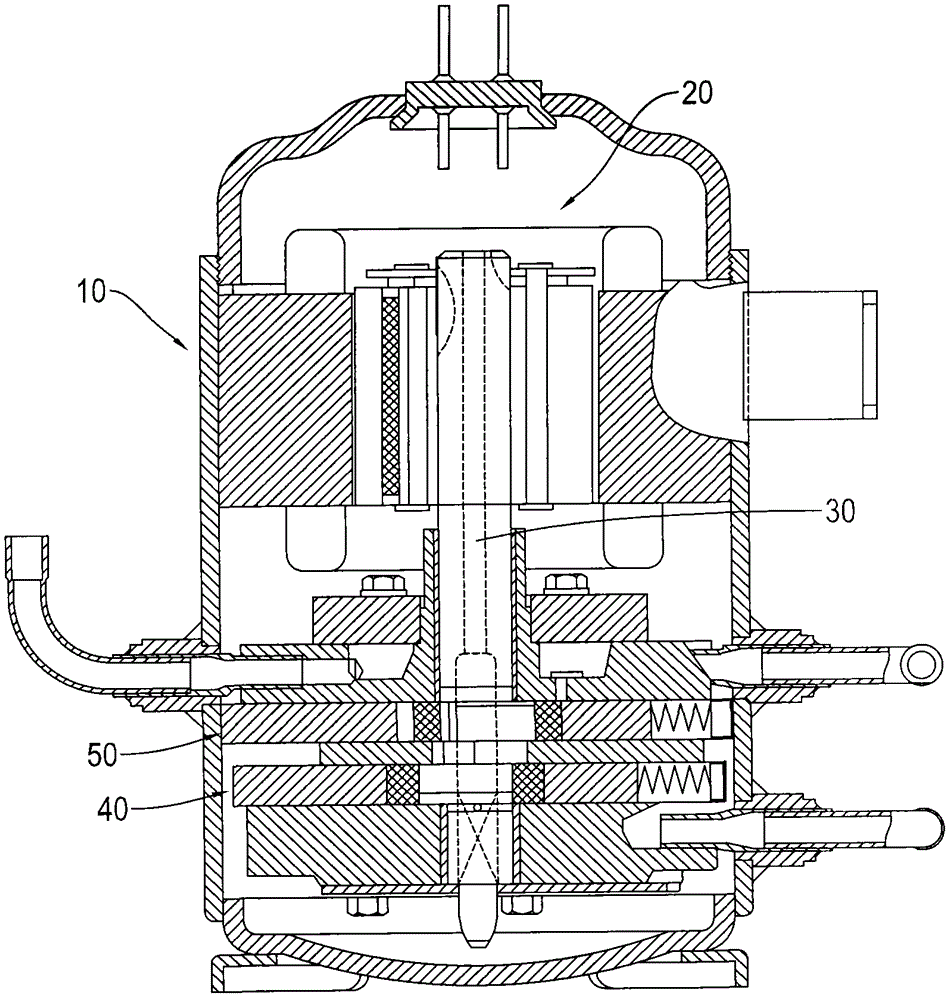

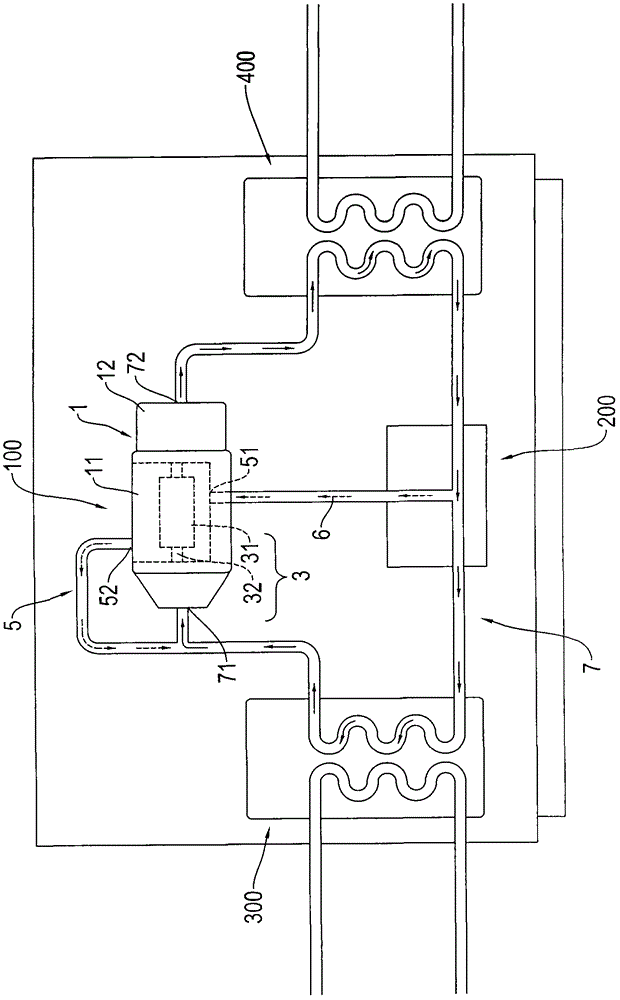

[0053] Please refer to figure 2 As shown, the present invention provides a multi-stage heat pump compressor. The multi-stage heat pump compressor 100 mainly includes a hermetic casing 1 , a partition assembly 2 , a driver 3 and at least two supercharging mechanisms 4 .

[0054] The partition assembly 2 is arranged in the airtight casing 1, and separates the airtight casing 1 into a first chamber 11 and a second chamber 12 which are isolated from each other, and the first chamber 11 is formed inside the second chamber 12; wherein The partition assembly 2 includes a partition 21 , two sealing elements 22 and a lubricant 23 , two sides of the partition 21 are respectively provided with a perforation 211 , and the lubricant 23 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com