Airbag plastic mould

A technology for plastic molds and airbags, which is applied in the field of plastic molds for airbags, and can solve the problems of inconvenient automatic retrieving mechanism for retrieving materials, easy generation of burrs, and easy product drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings.

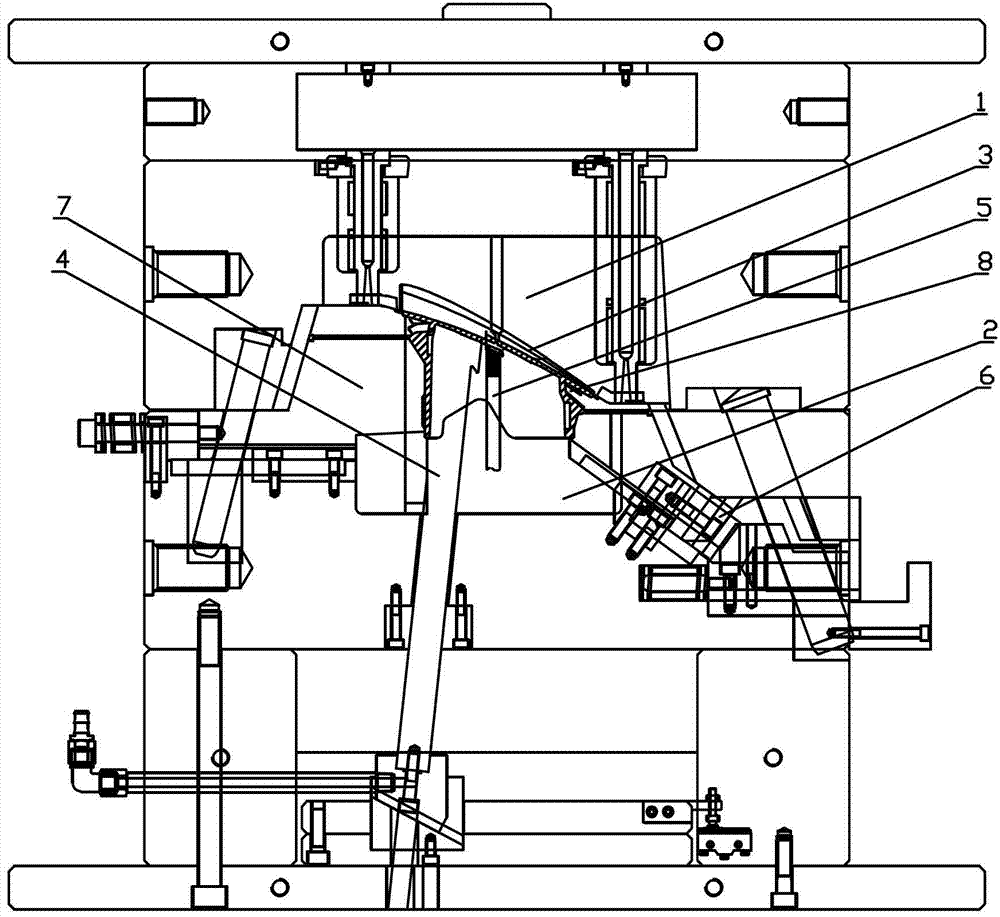

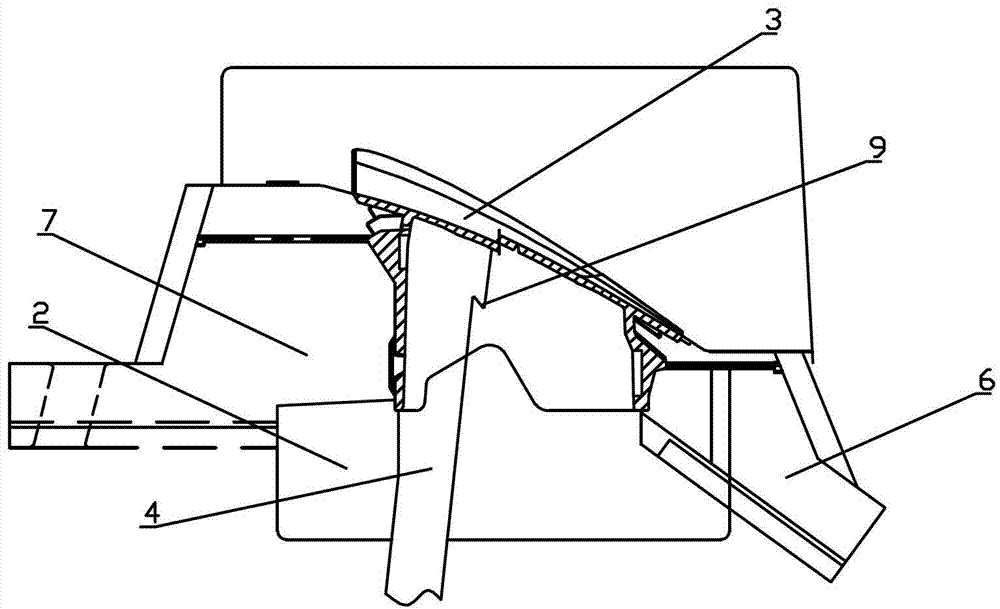

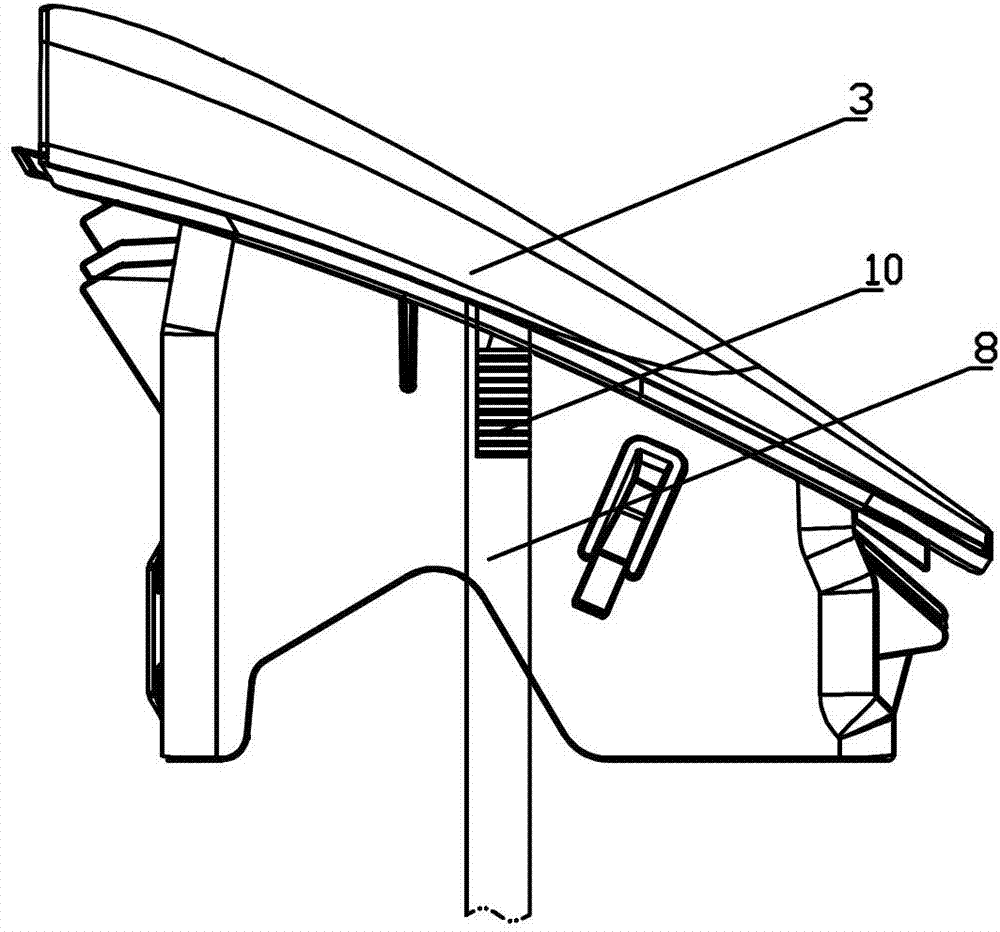

[0018] Attached figure 1 To attach Figure 7 , An airbag plastic mold, which includes a fixed mold core 1, a movable mold core 2 and a product cavity 3 located between the two; the product cavity 3 is respectively connected with the inclined top 4, the right slider 6 and the left slide Block 7; the inclined top 4 is slidingly fitted with the movable mold core 2 at the same time, one side of the upper end of the inclined top 4 is directly connected with the product cavity 3, and the other side is attached to the movable mold core 2; The side where the upper end is attached to the movable mold core 2 is provided with an undercut 9, and the movable mold core 2 is provided with a buckle position for interlocking with the undercut 9; the product cavity 3 is also connected with an anti-drop pin 5, The side surface of the anti-dropping needle 5 is provided with serrations 10 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com