Manual-pneumatic bi-component spray gun

A two-component, dual-purpose technology, applied in the direction of spraying devices, liquid spraying devices, single handheld devices, etc., can solve the problems of inconvenient construction, inconvenient use, and inability to adjust the flow rate online in real time, and achieve a simple and reasonable structure. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

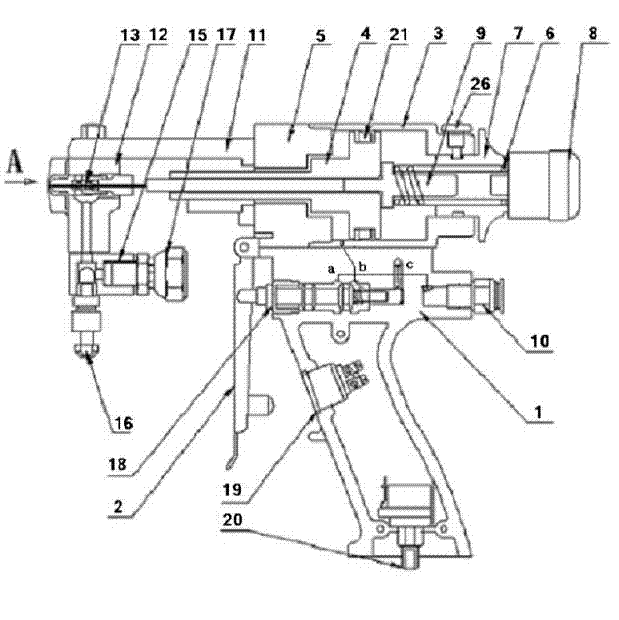

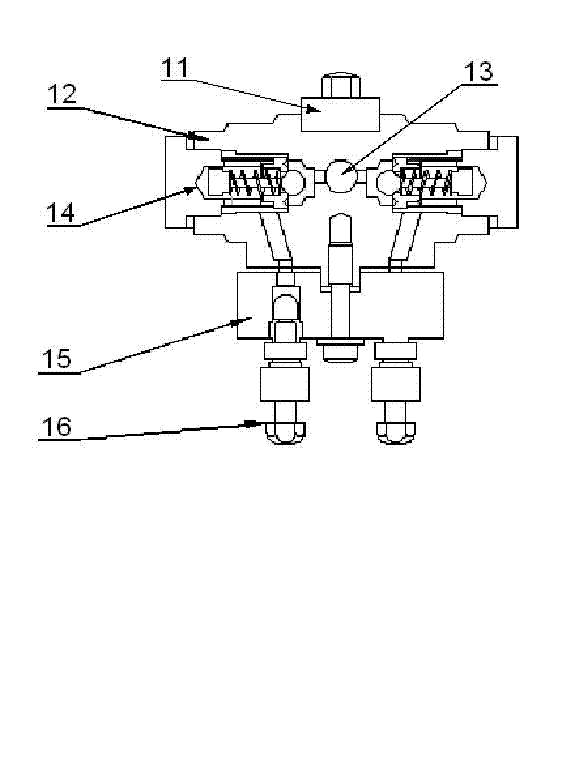

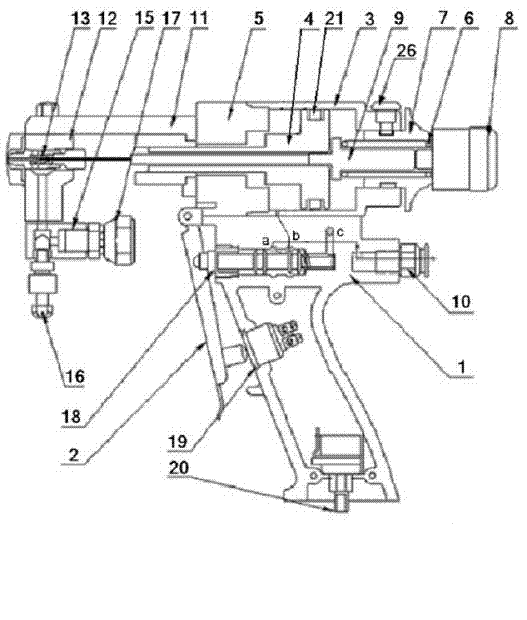

[0018] The accompanying drawing discloses a non-limiting schematic diagram of the specific structure of an embodiment of the present invention.

[0019] Referring to the accompanying drawings, 1 in the figure is the gun handle, 2 is the trigger, 3 is the cylinder barrel, 4 is the piston, 5 is the gun body, 6 is the return spring, 7 is the spring jacket, 8 is the valve stem adjustment button, and 9 is the Valve stem, 10 is the air pipe joint, 11 is the beam, 12 is the gun head, 13 is the mixing chamber, 14 is the filter check valve, 15 is the connection block, 16 is the manual valve, 17 is the feed joint, 18 is the pilot valve , 19 is a remote control switch, 20 is an adjustment knob, 21 is a seal, 22 is a sleeve pull rod, 23 is a rear limit plate of the pull rod, 24 is a pull rod adjusting nut, 25 is a pull rod handle, and 26 is an assembly positioning bolt.

[0020] The hand-pneumatic dual-purpose two-component spray gun of the present invention includes a gun head part, a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com