Belt scale remote support system and remote support method

A technology of remote support and belt scales, applied in transmission systems, measuring devices, instruments, etc., can solve the problems of not finding, measuring time lag, and powerlessness, etc., to improve the integrity rate and utilization rate, correct operation errors, and repair faulty equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

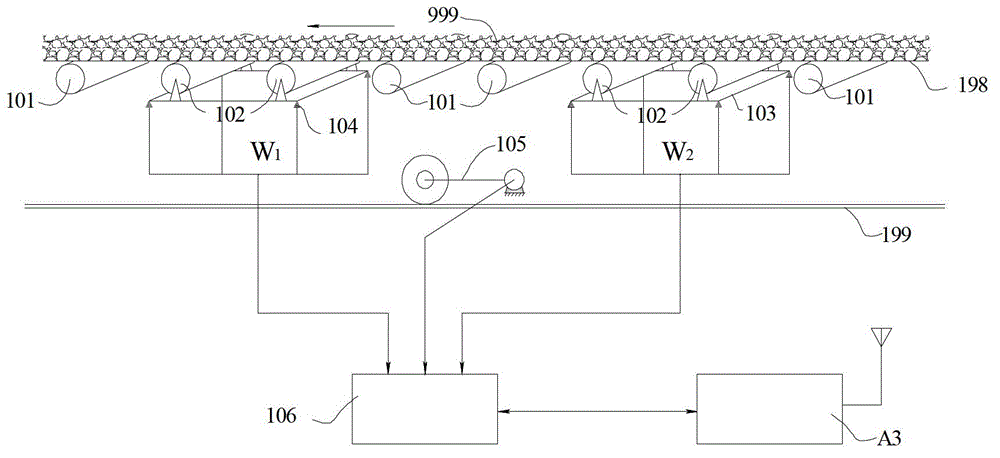

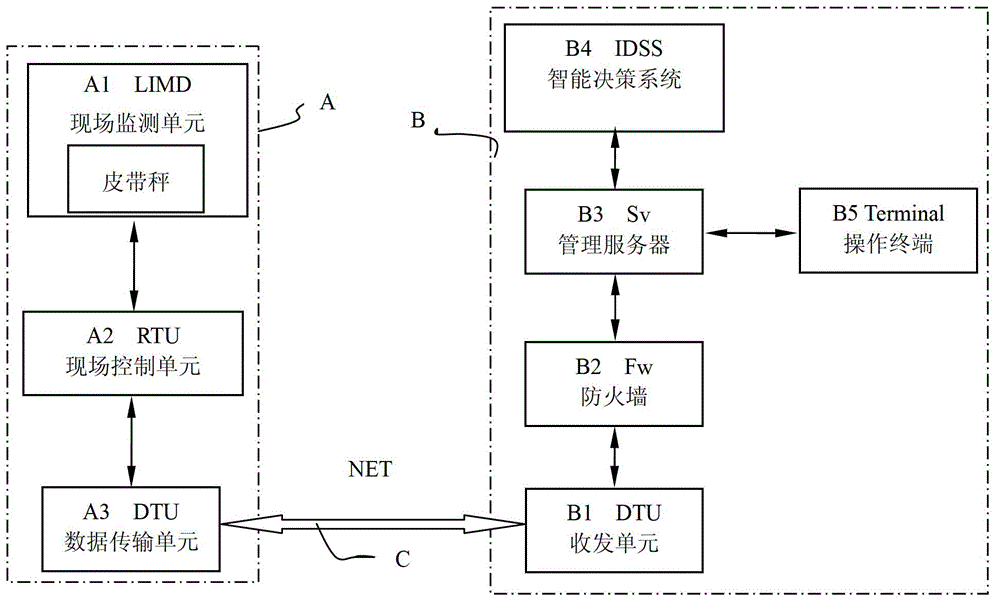

[0024] The specific situation of the client belt scale conveyor targeted by this embodiment is as follows figure 1 As shown, there are 2 belt scales W1 and W2 of any type that are basically the same, and the loaders of the two scales are installed independently of each other on the same loop formed by the process belt 198 for loading and the return belt 199 for no load. on the belt conveyor. W1 and W2 are separated by conveying rollers 101 (or not separated by conveying rollers). The weighing idler 102 transmits the weight of the material 999 to be weighed to the load cell 104 through the scale frame 103, the displacement sensor 105 detects the speed of the belt, and the weight and speed signals are introduced into the weighing instrument 106 for basic data processing to calculate the cumulative weight of the material , and then fed into the data transmission unit A3 (DTU), it can be transmitted to the data processing center of the management terminal B through the public wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com