Water oil contamination cleaning robot

A robot and oil pollution technology, applied in the field of robots, can solve the problems of waste of materials, low efficiency, high energy consumption, etc., and achieve the effect of simple and easy access to materials, increased contact area, and large mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

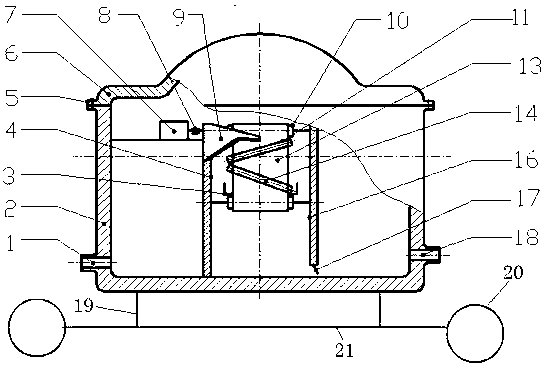

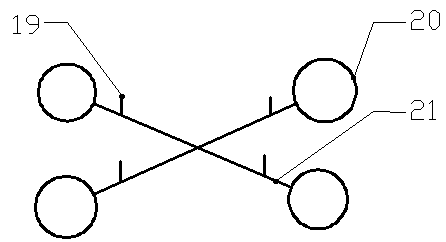

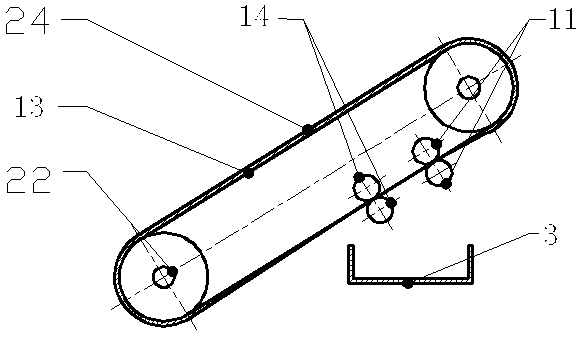

[0024] As shown in Fig. 1 to Fig. 4, the above-water oil pollution cleaning robot of the present invention comprises an oil-water mixture inlet 1, a casing 2, a dirty oil collection tank 3, a left isolation baffle 4, a flange 5, a case cover 6, a motor 7, Coupling 8, oil guide groove 9, roller 10, first and second two-way tapered rollers 11, 14, conveyor belt 13, right isolation baffle 16, control valve 17, water outlet 18, anti-floating flexible connector 19, buoyancy device 20, support frame 21. The shaft sleeve 22 is coated with a lipophilic and hydrophobic material layer 24 .

[0025] The buoyancy device 20 is installed under the box body 2, and the oil-water mixture treatment device is installed in the box body 2, and the left and right isolation baffles 4, 16 are arranged to form left, middle and right chambers, and the oil absorption treatment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com