Laser material distributing, lying and leveling machine

A leveling machine and laser technology, applied in the erection/assembly of bridges, roads, bridges, etc., can solve the problems of waste of paving materials, unreachable, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

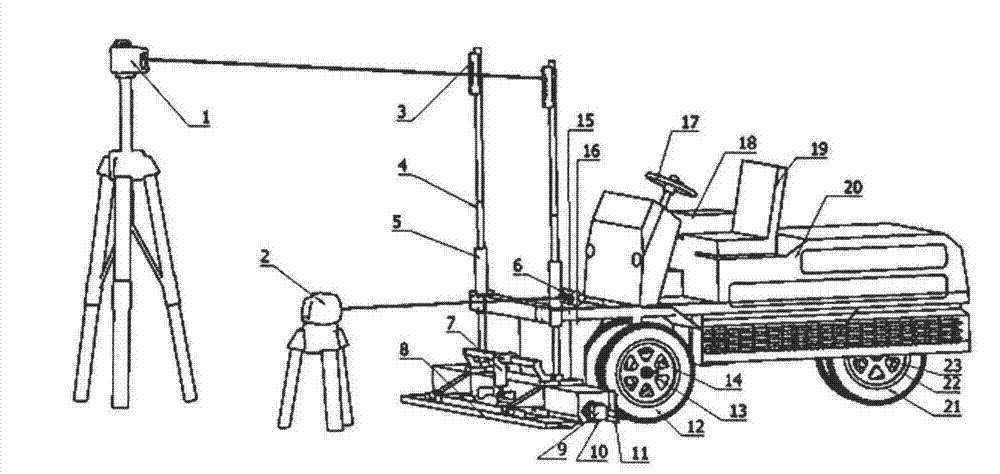

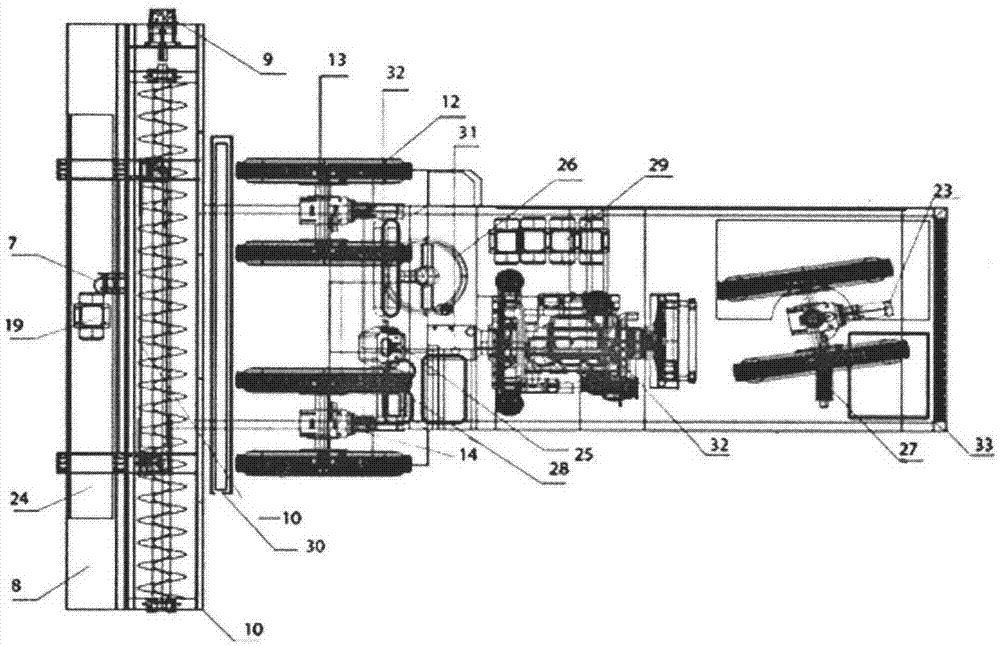

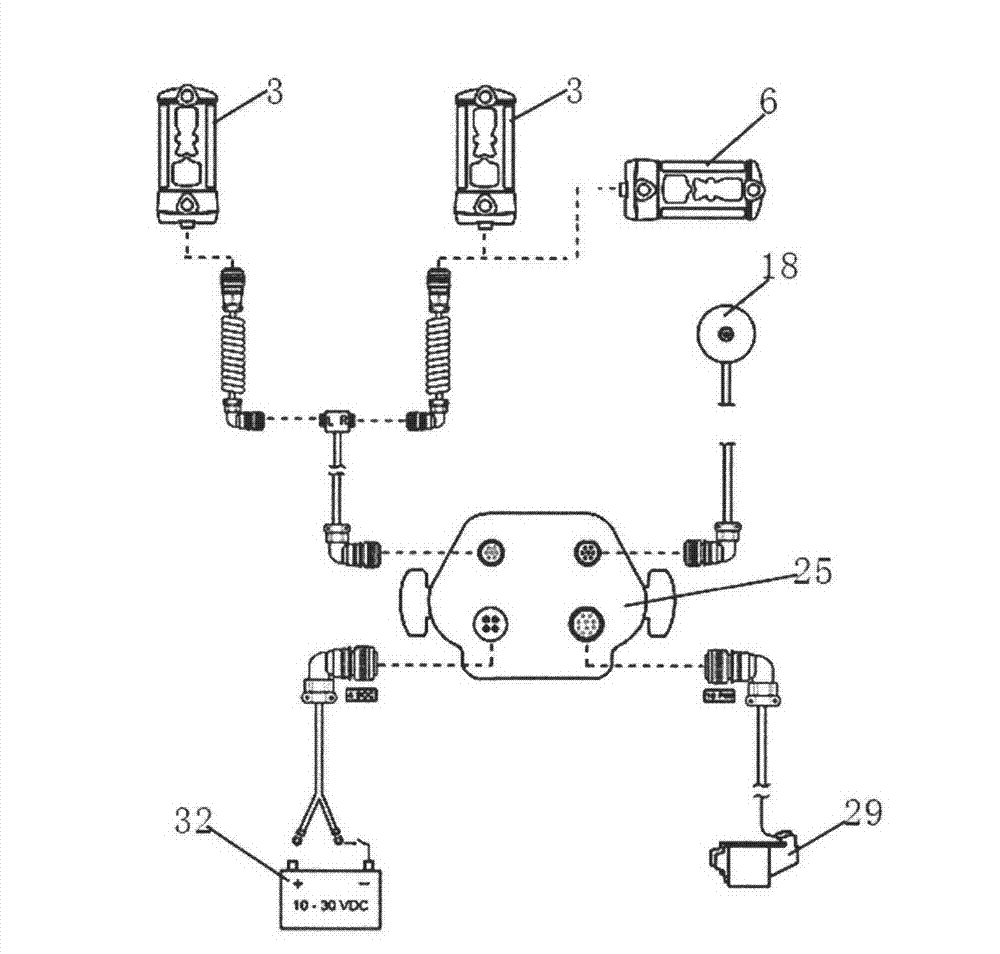

[0026] Below in conjunction with accompanying drawing, further illustrate how the present invention is realized:

[0027] as attached figure 1 , 2 . As shown in 3, the laser cloth paving and leveling machine includes: laser control system, hydraulic system, leveling head, and cloth system. The construction requires setting horizontal beams, inclined beams at different angles and vertical beams. The mechanical laser receivers are respectively installed on the left and right sides of the machine and connected to the upper end of the piston rod 4 of the leveling hydraulic cylinder 5 of the mechanical leveling head, and the cylinder body of the leveling hydraulic cylinder 5 and the The mechanical main frame 20 is connected, the upper end of the piston rod 4 is equipped with a laser receiver 3, the lower end of the piston rod 4 is connected with the leveling head, the laser receiver 3 transmits the received signal to the laser controller 25, and the laser controller 25 outputs acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com