Multi-shaft carving machine

A technology of engraving machines and rotary motors, applied in the field of engraving machines, can solve the problems of low precision of workpiece clamping devices, affect the quality and efficiency of processing, and cannot process complex parts, etc., so as to improve engraving efficiency, good economic benefits and Social benefits and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

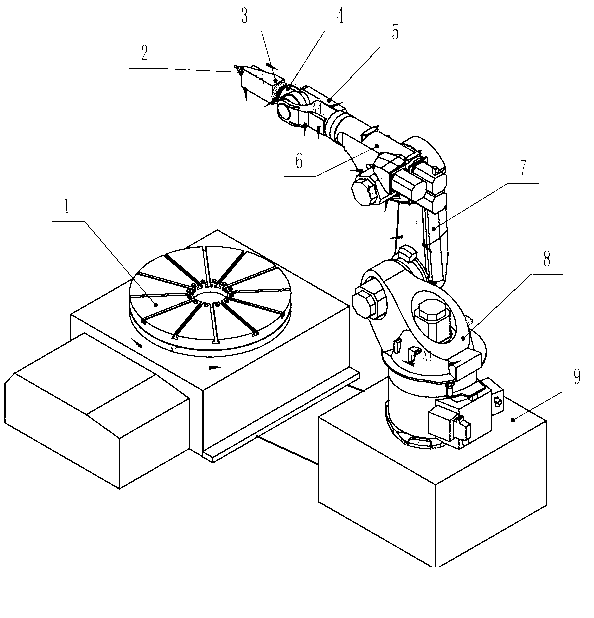

[0019] Referring to the accompanying drawings, the present invention includes a base 9 and a rotary table 1. A first rotary node is arranged on the upper part of the base 9, and a first rotary motor and a first drive system are arranged inside the first rotary node. The first drive system is placed vertically, the first rotary motor is engaged with the first drive system through a first gear mechanism, and a first rotary arm 8 is arranged on the upper part of the first drive system. The end of the arm 8 is provided with a second pivot point;

[0020] A second rotary motor and a second drive system are provided in the second rotary node, the second drive system is placed horizontally, and the second rotary motor and the second drive system are meshed through a second gear mechanism. One side of the second drive system is provided with a second rotary arm 7, and a third rotary node is provided at the end of the second rotary arm 7;

[0021] A third rotary motor and a third driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com