Working machine

一种作业机械、作业装置的技术,应用在机械驱动的挖掘机/疏浚机、移土机/挖土机、上部结构分总成等方向,能够解决发动机室高度尺寸增加等问题,达到舒适操作性、提高作业性、减小压迫感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, embodiments of the working machine of the present invention will be described based on the drawings.

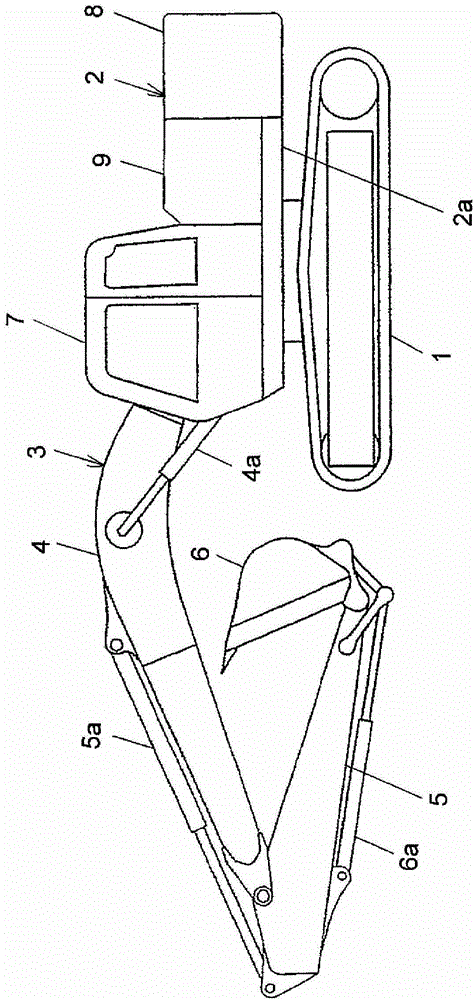

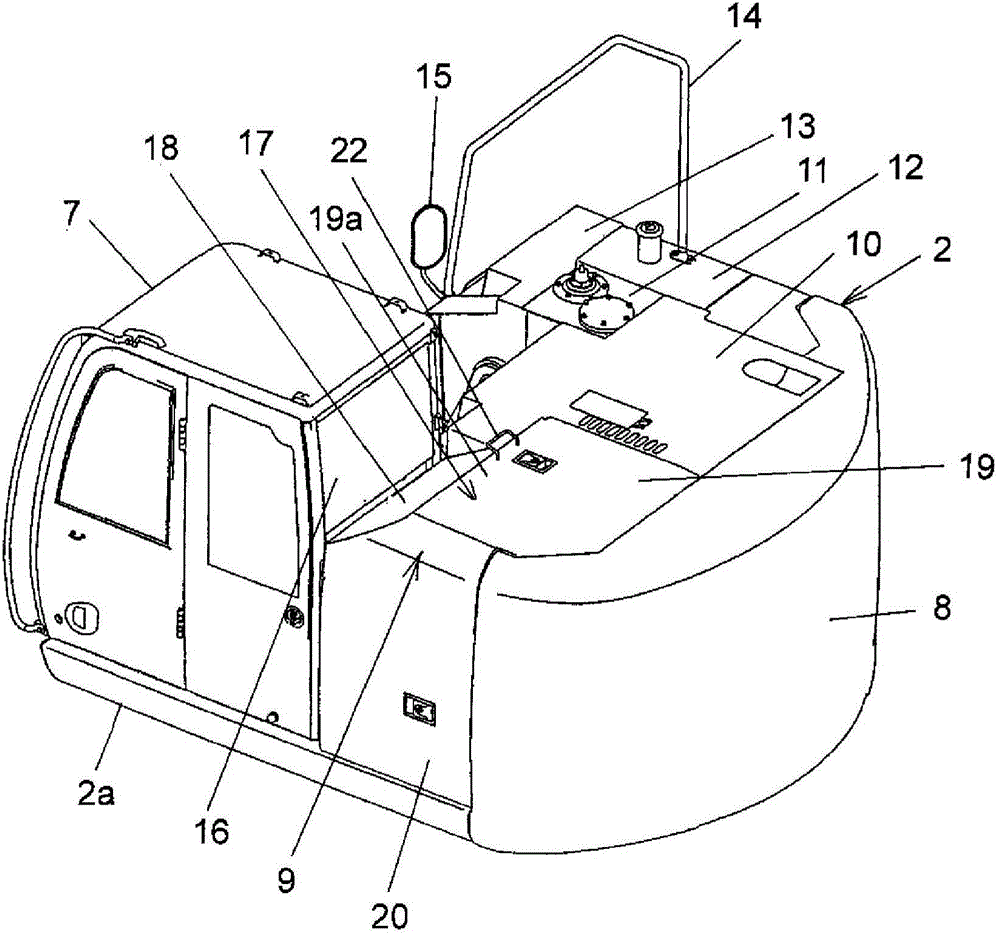

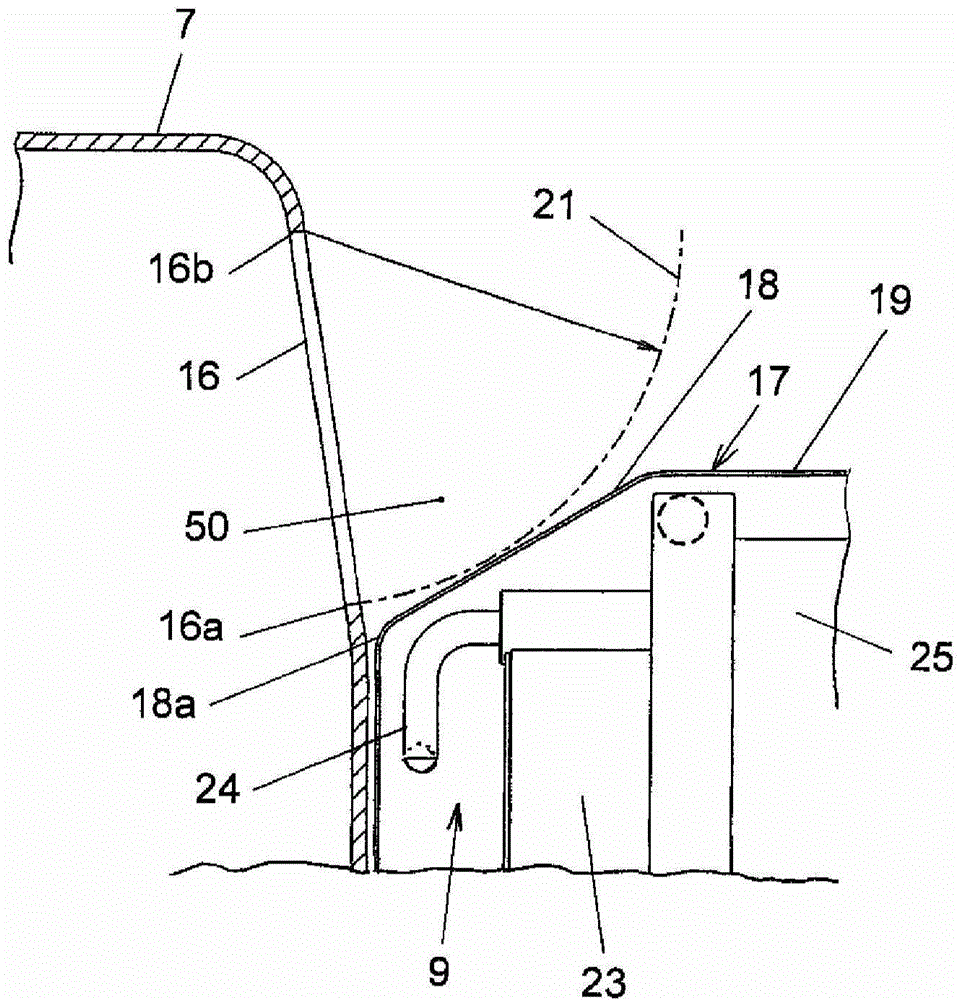

[0035] figure 1 It is a side view showing a hydraulic excavator constituting the first embodiment of the working machine of the present invention, figure 2 yes means figure 1 A perspective view of a revolving body included in the hydraulic excavator shown above, image 3 yes figure 2 It is an enlarged side sectional view of main parts of the rotary body shown.

[0036] The working machine according to the first embodiment of the present invention is constituted by, for example, a hydraulic excavator. Such as figure 1 As shown, the hydraulic excavator includes a traveling body 1 , a revolving body 2 disposed on the traveling body 1 , and a work implement 3 mounted on the revolving body 2 so as to be rotatable in an up-down direction. The working device 3 includes: a boom 4 mounted on the revolving body 2 so as to be rotatable in the vertical direction; a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com