A temporary support hanging device

A hanging device and temporary support technology, which is applied in the direction of supporting the roof beam of the mine roof, mining equipment, earthwork drilling, etc., can solve the problems of inconvenient operation, small fixing area and poor stability, and reduce accidents. and economic losses, more stable hanging points, and improved support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

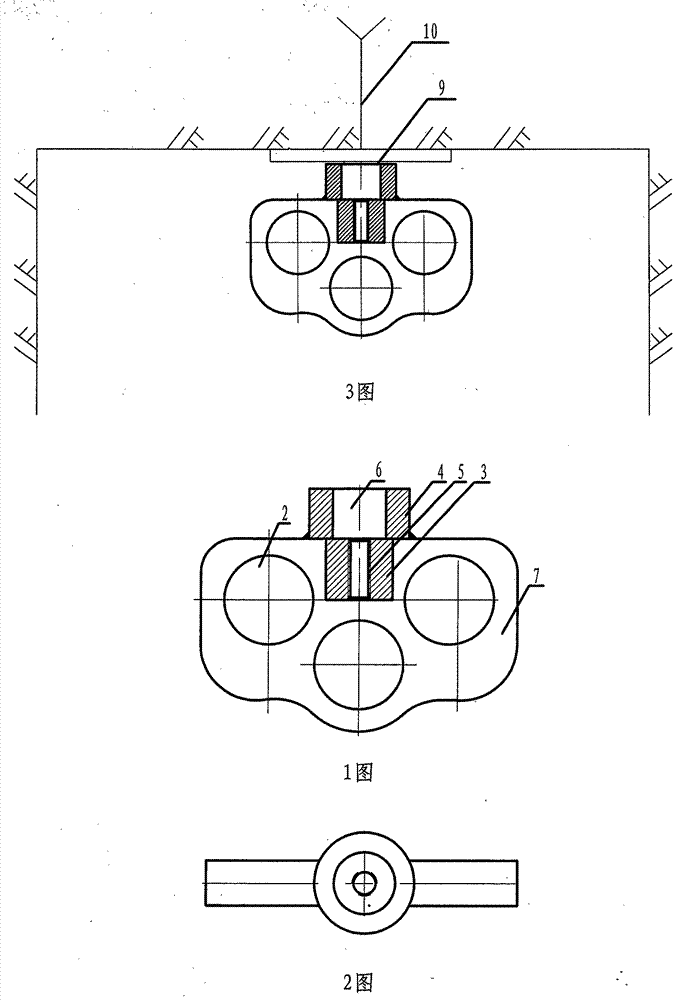

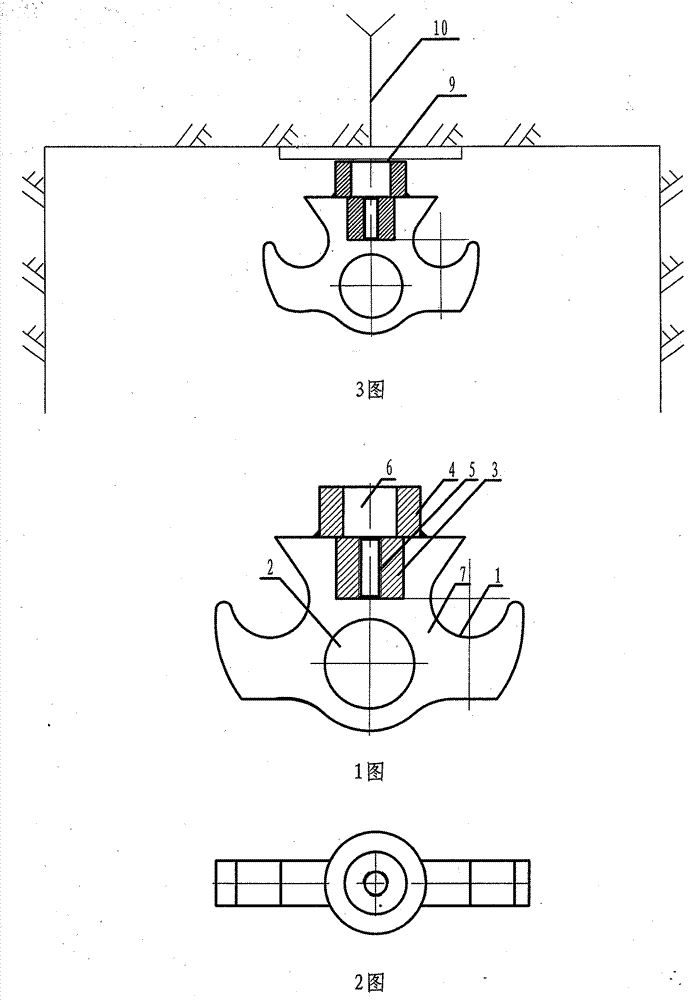

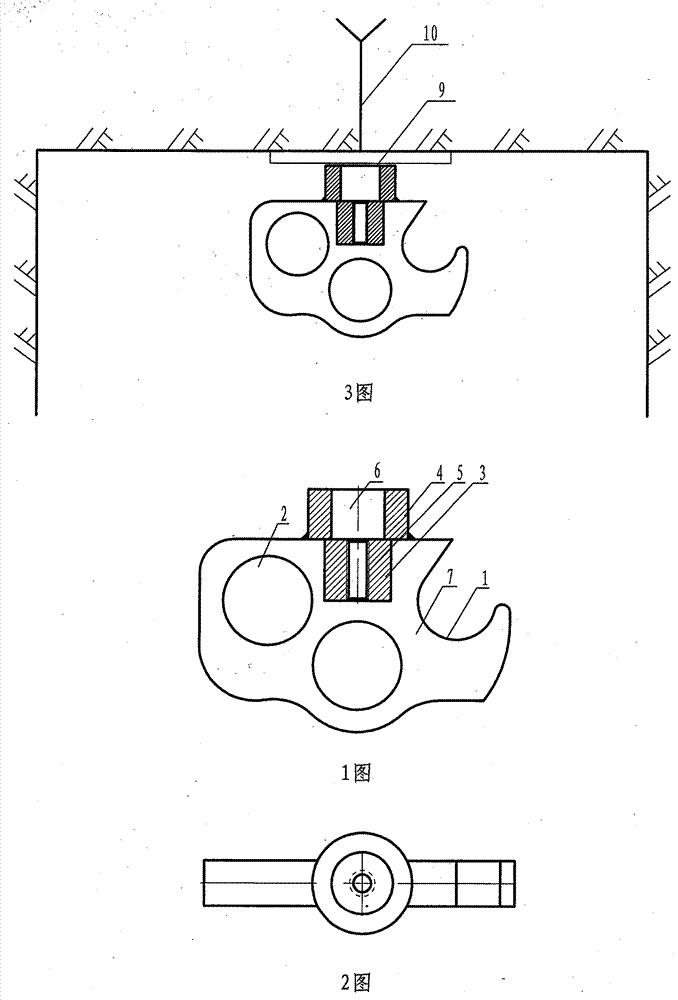

[0047] 1. See figure 1 , the invention includes a bearing column, a circular ring and a plane plate with through holes on it. Figure 1 is the front view of the hanging device, Figure 2 is the top view, in which the circular ring (4) is fixed concentrically with the bearing column (3), and the plane plate (7) is matched with the bearing column through the rectangular groove on its upper part and For fixed connection, circular through holes (2) are arranged on the plane plates on both sides and below of the bearing column as suspension rings. Figure 3 is a front view of its working state. In the figure, the hanging device cooperates with the external bolt of the anchor rod through the screw hole (5) on the bearing column, and the circular ring on the upper part of the bearing column cooperates with the fixing nut of the anchor rod, and is fixed on the top plate under.

[0048] 2. See figure 2 , Figure 1 is the front view of the hanging device, Figure 2 is its top view, in wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com