Sewage treatment process for realizing sludge reduction by taking elemental sulfur as medium

A sewage treatment and sludge reduction technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problem of large excess sludge production and achieve cost savings , simple equipment, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

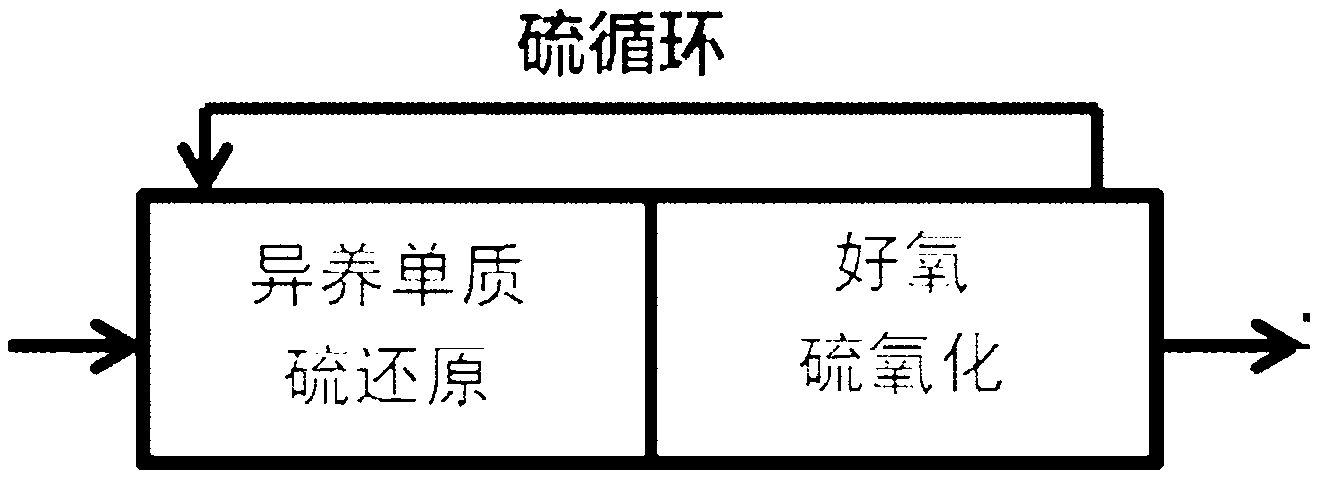

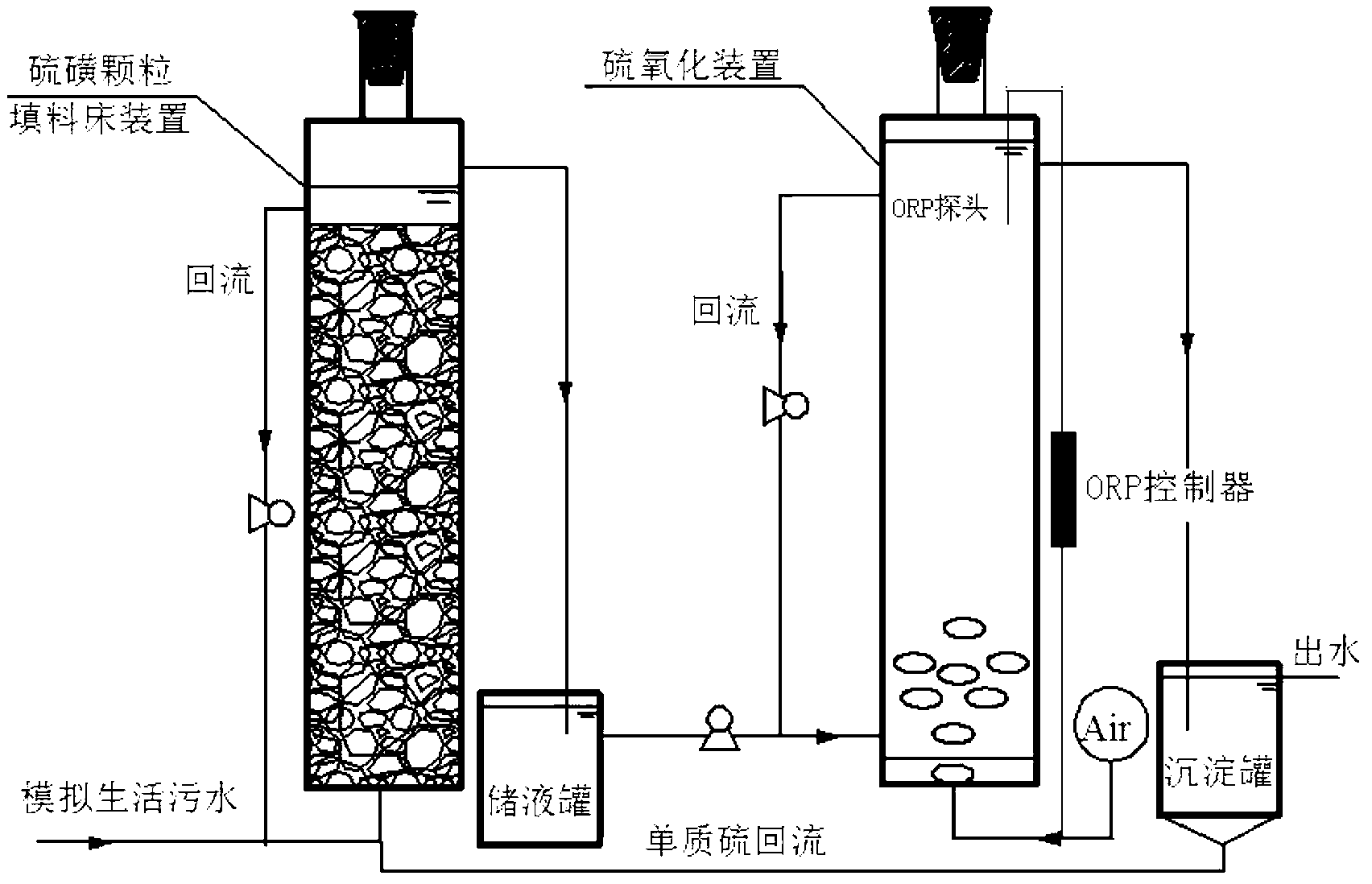

[0048] A sewage treatment process using elemental sulfur as a medium to achieve sludge reduction, including the following steps, the process design principle is shown in figure 1 :

[0049] (1) Process installation diagram

[0050] The sulfur reduction reactor in this process adopts an upflow sulfur packed bed biofilm reactor, its dissolved oxygen concentration is less than 0.2mg / L, the total volume of the reactor is 3.6L, the volume of the packing sulfur block is 1.32L, and the effective volume is 2.28L , made of plexiglass.

[0051] The sulfur oxidation reactor adopts an upflow aerobic reactor with a total volume of 2L and a total height of 80cm. There is an aeration device at the bottom and it is made of plexiglass.

[0052] (2) Hanging film of sulfur reduction reactor

[0053] After fixing the sulfur particle packing in the sulfur reduction reactor, inoculate the activated sludge (from the urban sewage treatment plant) from the top of the reactor, and then feed the dome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com