Multi-cutter processed numerically-controlled double-slider power head of valve body

A dual-slider, power head technology, applied in metal processing equipment, metal processing mechanical parts, driving devices, etc., can solve the problems of high cutting heat, large cutting force, large workpiece deformation, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings. Except the invention point of the present invention, all the other technologies are the same as the prior art.

[0037] The valve bodies processed by the present invention include: gate valves, globe valves, check valves, butterfly valves, pressure reducing valves, etc., as long as they are valve body parts with flange layout, the present invention can be processed. Except the invention point of the present invention, all the other technologies are the same as the prior art.

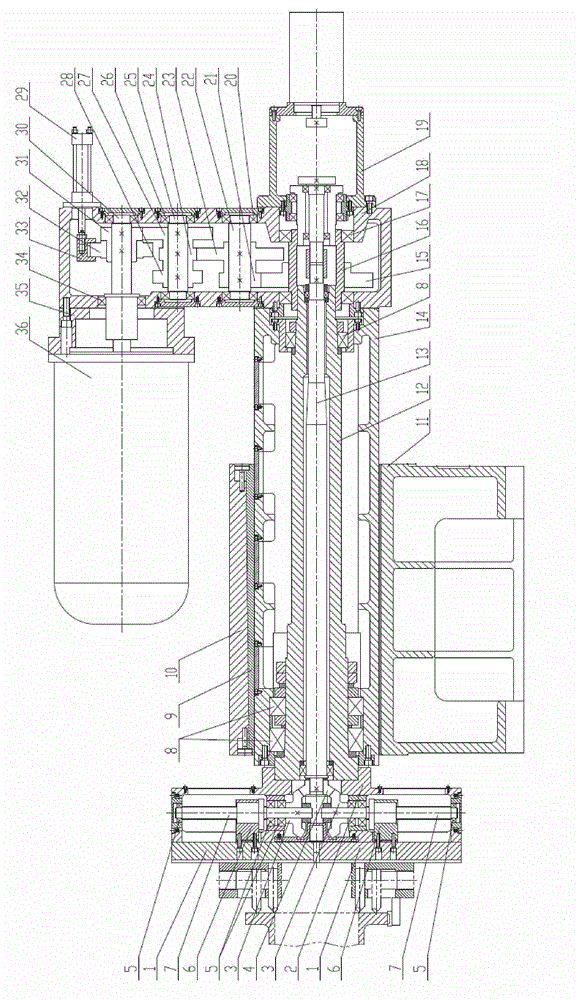

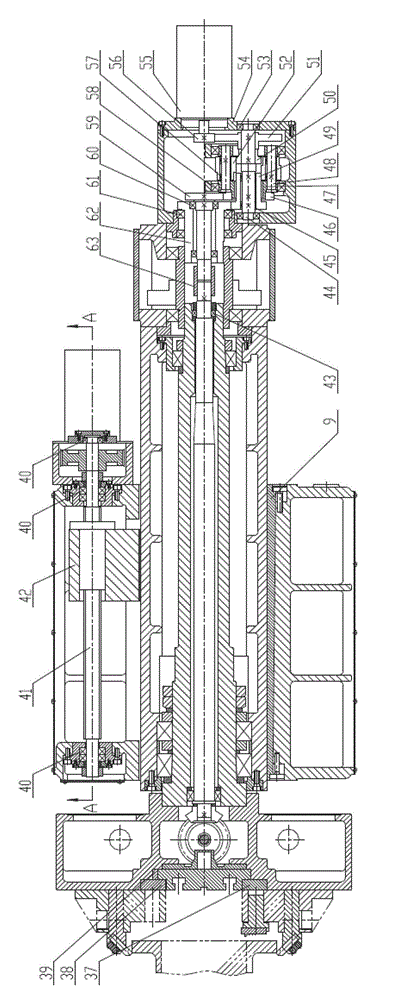

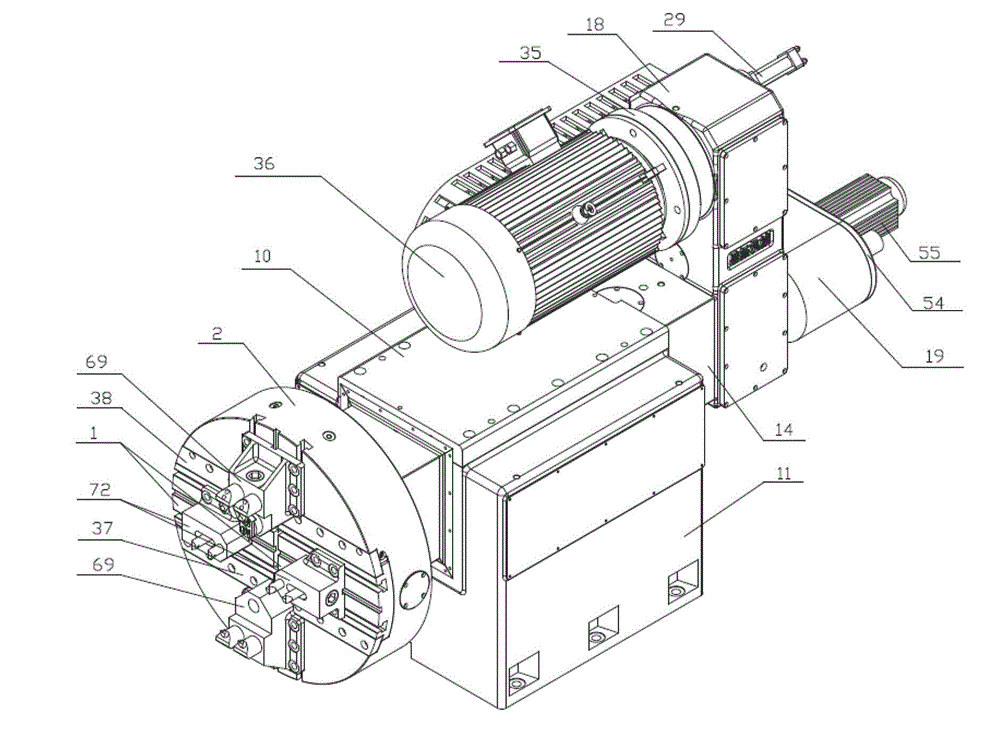

[0038] Multi-knife processing valve body CNC double-slider power head, including ram seat 11, square ram 14, flat rotary disc 2, slider 1, spindle box 18, differential feed box 19, tool holder mechanism, square slide Pillow 14 is installed on the ram seat 11, and the front end of square ram 14 is connected with flat rotary disc 2, and the knife rest mechanism includes knife rest 69, knife rest 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com