Cutter suction dredger over-water floating pipe hydraulic fast connector

A cutter suction dredger and floating pipe technology, which is applied to mechanical equipment, couplings and other directions, can solve problems such as restricting the development of pipeline laying technology and construction technology, affecting the overall benefits of dredging and filling projects, and achieving significant economic benefits. And social benefits, improve laying efficiency, make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

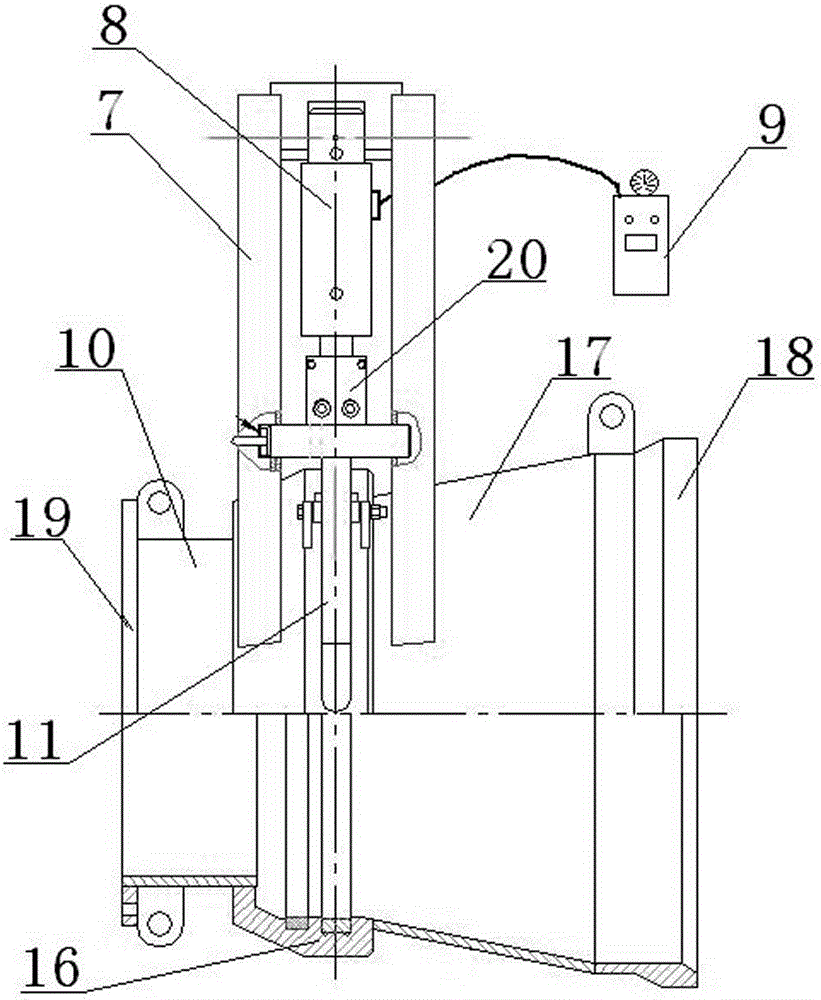

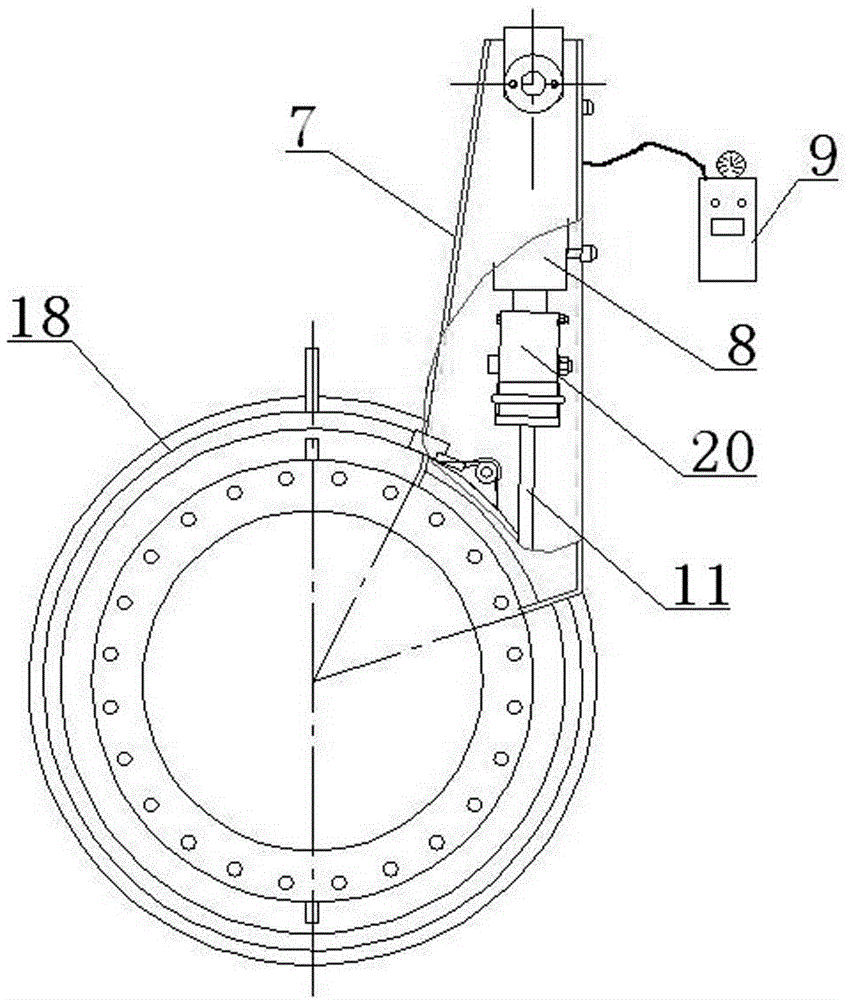

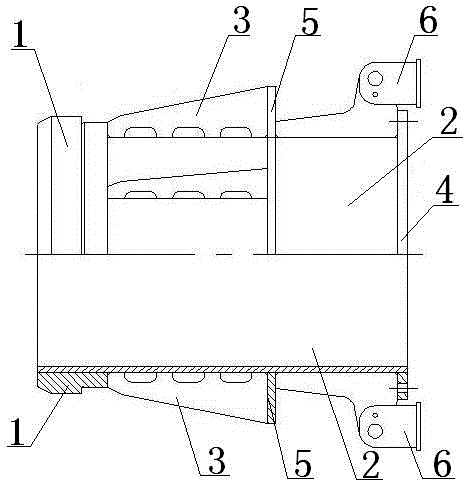

[0053] Refer to attached Figure 1~4 :

[0054] The hydraulic quick joint of the floating pipe of the cutter suction dredger includes a connecting head, a connecting sleeve, a hydraulic transmission device and a steel belt retractable locking device; the hydraulic transmission device is installed on the outer surface of the connecting sleeve, and the hydraulic transmission device and the steel belt retractable The locking device is connected through the connector 20; when in the connected state, the connecting head is locked in the connecting sleeve.

[0055] The connector includes a guide head 1 , a guide rib 3 , a ring plate 5 , a connector body 2 , a flange 4 and a supporting foot 6 . The connector is a hollow structure, the first end of the connector is equipped with a guide head 1, and the tail end is installed with a flange 4; the front end of the guide head 1 is provided with chamfers for smooth transition, and the rear end of the guide head is turned into a step to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com