Rolling type high-temperature sample-dyeing-machine universal-cup turnplate

A technology of sample dyeing machine and turntable, which is applied in the direction of processing textile material dyeing devices, etc. It can solve the problems of inability to replace different types of dyeing cups, increase production costs, and lack of interchangeability, so as to achieve reasonable structure, energy saving, and increase production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

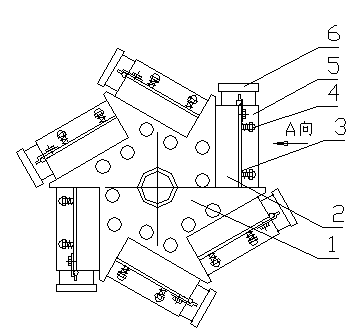

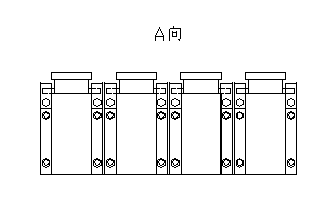

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] Referring to the accompanying drawings, a universal cup turntable of a tumbling high-temperature dyeing machine includes a turntable 1, screws 4, and a dyeing cup 6. It is characterized in that: the turntable 1 is provided with a dyeing cup fixing seat 2, and the dyeing cup fixing seat is semicircular The shaped hole is provided with a Huff-type cup cover 5, and the Huff-type cup cover is connected with the dyeing cup fixing seat by a screw 4, and the screw 4 is covered with a spring 3, which is convenient for the dyeing cup 6 to be put into the upper semicircle of the dyeing cup fixing seat 2. The circular hole groove that hole and Haff formula cup cover 5 form. Several dyeing cup fixing seats 2 are arranged on the turntable 1 . Described dyeing cup fixing seat 2 is provided with several semicircular holes for placing dyeing cups 6 . The dyeing cup holder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com