Steel can track brake

A technology of brakes and steel tanks, applied in elevators, transportation and packaging, etc., can solve the problems of high cost of wire rope braking system, high operation and maintenance costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

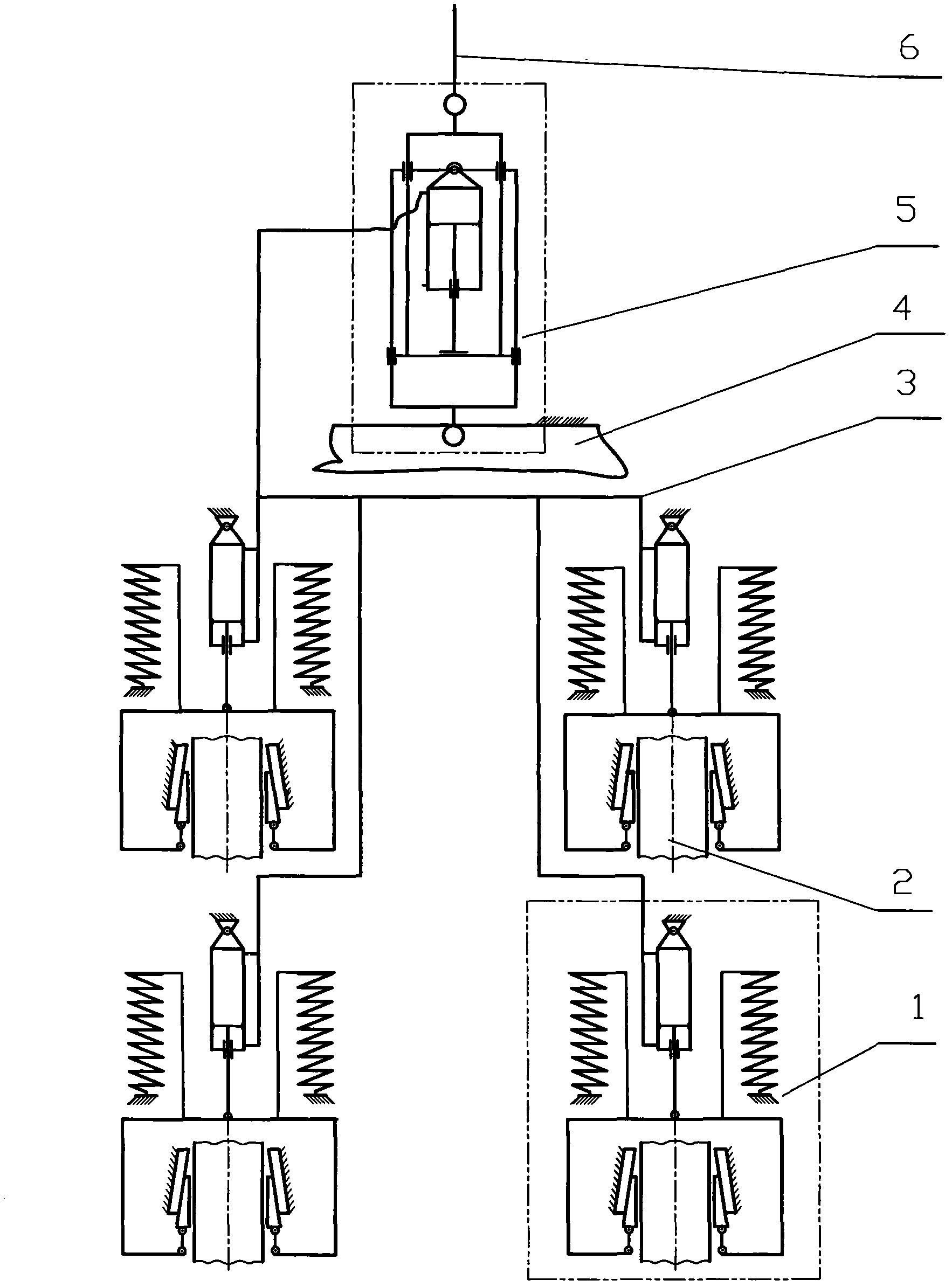

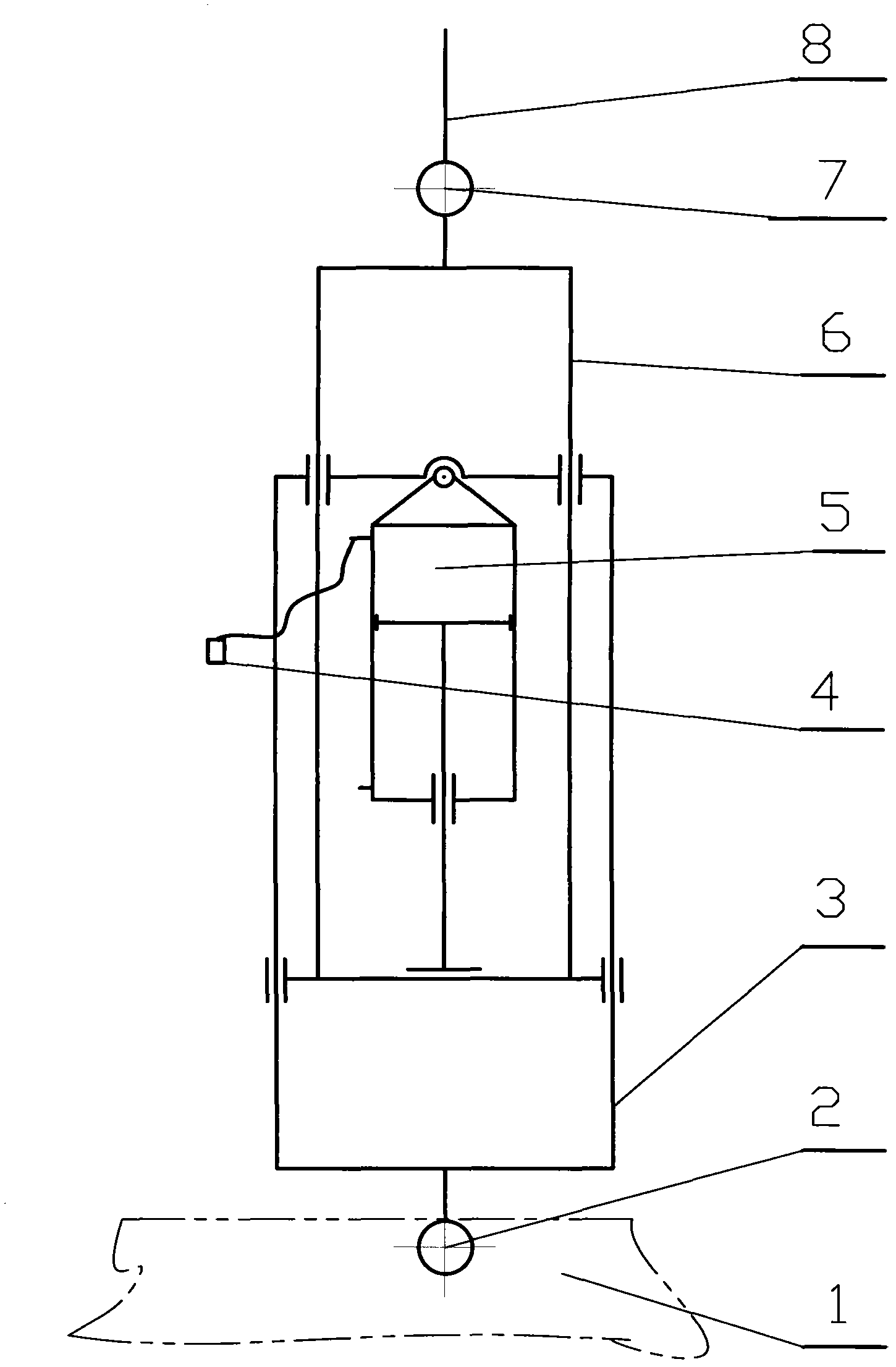

[0013] The steel tank road brake is composed of a suspension device, pipelines and multiple sets of braking units. The suspension device is installed between the hoisting wire rope and the lifting container, and the braking unit is installed on the lifting container. The unit's cylinder connections (such as figure 1 shown). When the hoisting system is in normal operation, the hoisting wire rope always maintains tension under the gravity of the hoisting container and the lifting object, and the oil in the oil cylinder of the suspension device is pressed into the oil cylinder of each brake unit under the tension of the hoisting wire rope, pushing the oil cylinder to extend. Long, overcome the spring force, drive the brake pads to move downward along the slope, out of contact with the steel tank road, the brake does not brake. When the hoisting wire rope breaks, the tension of the wire rope drops rapidly, the oil pressure of the oil cylinder of the suspension device drops accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com