Heavy-duty rack

A shelf and heavy-duty technology, which is applied in the direction of transportation, packaging, and storage devices, can solve the problems of hidden dangers to the personal safety of workers, less heavy cargo, and difficult disassembly, etc., and achieve the goal of solving personal safety problems, low production costs, and saving materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

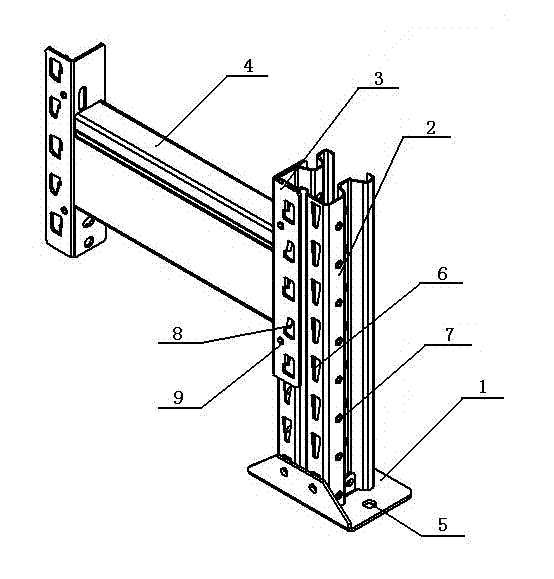

[0022] further combination figure 1 A further description of a heavy-duty shelf: before use, the fixed base 1 is fixed on the ground through the through hole 5 with expansion screws, the five-tooth hanging piece 3 and the beam 4 are welded together, and the fixed base 1 and the column 2 are welded together Or fix the connection by fixing screws; when assembling and using, place the hanging teeth 8 on the five-tooth hanging piece 3 in the trapezoidal hook through hole 6 of the column 2 for fixed connection, and then connect the first pin hole 7 on the column 2 and the five-tooth hanging piece The second latch hole 9 on the 3 is aligned with the fixing bolt for fixed connection.

[0023] Since the column 2 and the five-tooth hanging piece 3 are evenly provided with the trapezoidal hook through hole 6, the first bolt through hole 7, the hanger tooth 8 and the second bolt through hole 9, it is possible to adjust the trapezoidal hook through hole 6, The installation positions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com