Feeding bottle with upper portion of feeding bottle body being of double-layer structure

A technology of double-layer structure and single-layer structure, which is applied in feeding bottles and other directions, can solve the problems of inconvenient heating, inconvenient cooling, and few applications, and achieve the effect of facilitating heating or cooling and avoiding cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

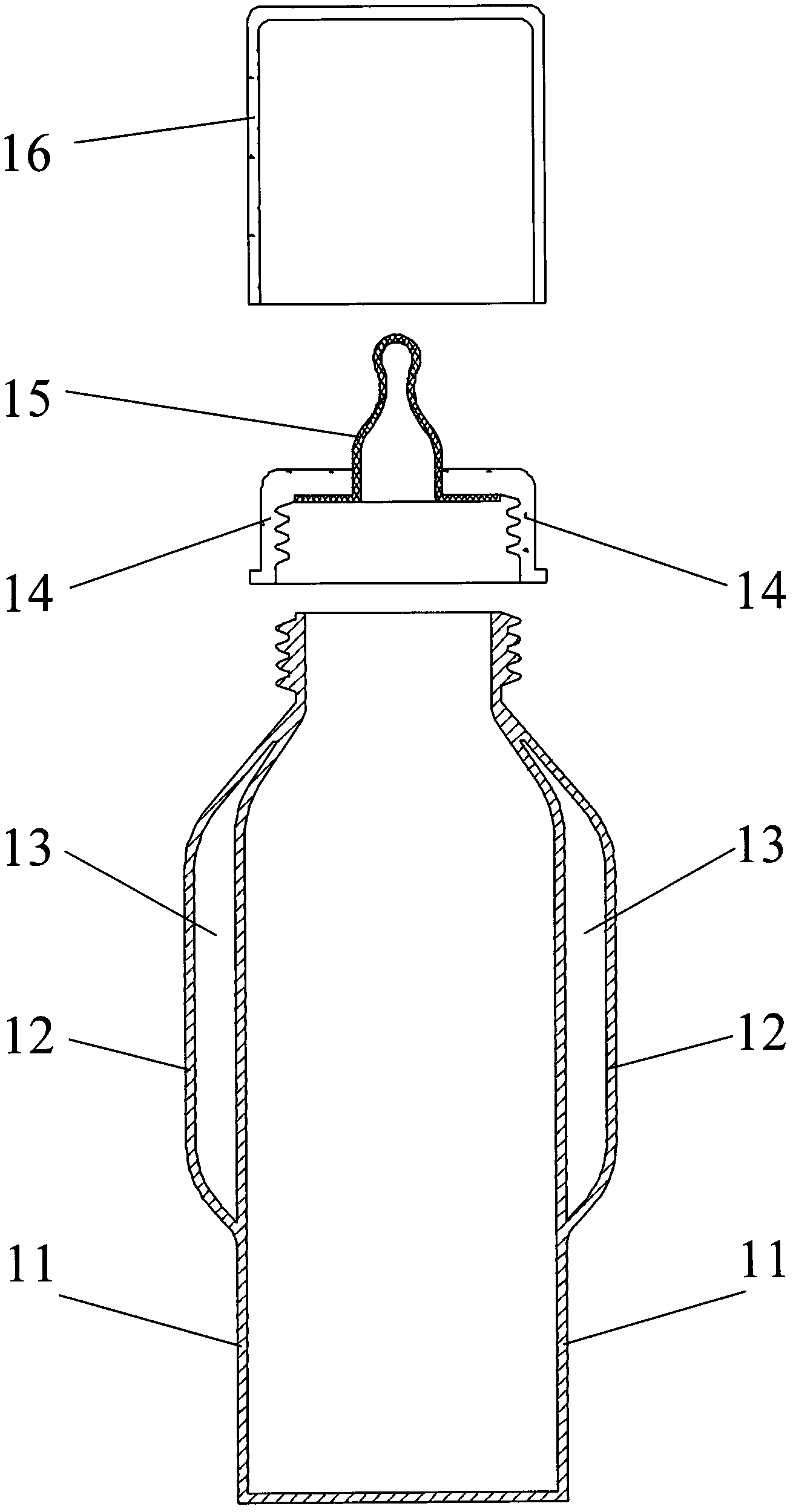

Embodiment 1

[0014] This embodiment illustrates a solution for realizing the integral molding of the present invention by using the same material. see figure 1 , this embodiment comprises single-layer feeding bottle main body 11, feeding bottle outer layer 12, feeding bottle cap 14, pacifier 15, dust cover 16, between single-layer feeding bottle main body 11 and feeding bottle outer layer 12 is insulation layer 13, and insulation layer 13 can be Air, or a vacuum or other insulating material. The outer layer 12 of the feeding bottle and the main body 11 of the single-layer feeding bottle are integrally formed of the same material. The double-layer structure formed by the outer layer 12 of the feeding bottle and the main body 11 of the single-layer feeding bottle is on the upper part of the feeding bottle body, and the lower part of the feeding bottle body is a single-layer structure. When mixing milk, it is convenient to sense the temperature of the milk, as well as heating and cooling, an...

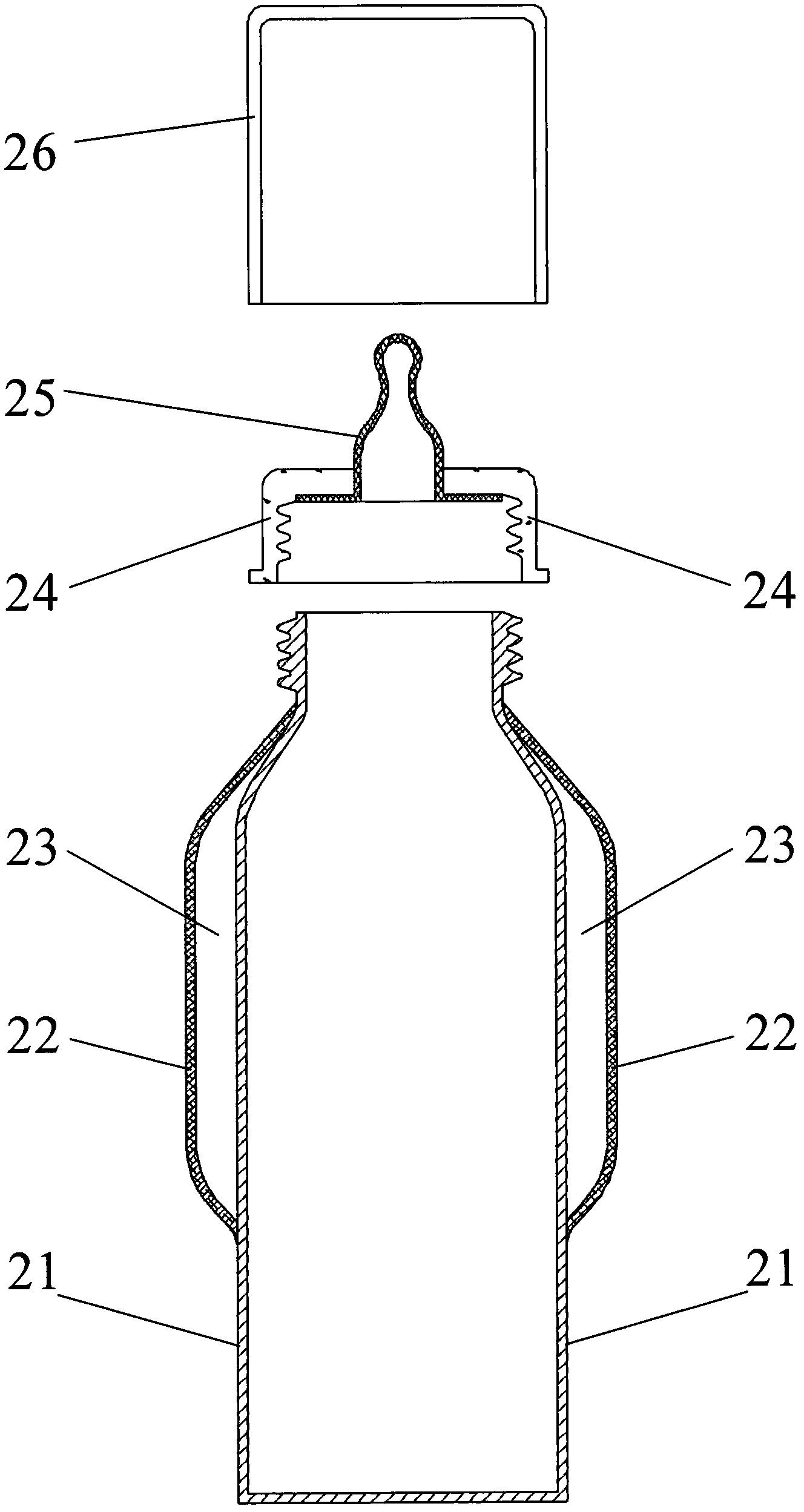

Embodiment 2

[0016] This embodiment illustrates a scheme for realizing the single-layer feeding bottle body 21 and the feeding bottle outer layer 22 respectively manufactured by using different materials. see figure 2 , this embodiment comprises single-layer feeding bottle main body 21, feeding bottle outer layer 22, feeding bottle cap 24, pacifier 25, dustproof cover 26, is insulation layer 23 between single-layer feeding bottle main body 21 and feeding bottle outer layer 22, and insulation layer 23 can be Air, or a vacuum or other insulating material. The outer layer 22 of the feeding bottle and the main body 21 of the single-layer feeding bottle are made of different materials. It is a single-layer structure, so that it can realize the dual functions of conveniently mixing milk and keeping milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com