Impurity removal device of corncob lift conveyer of corn harvester

A technology of corn harvester and elevator, which is applied to harvesters, agricultural machinery and implements, applications, etc., and can solve problems such as jammed ear elevator moving parts and difficult-to-discharge devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

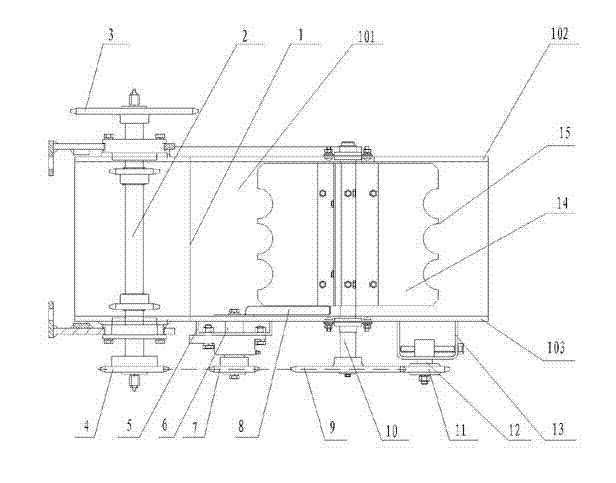

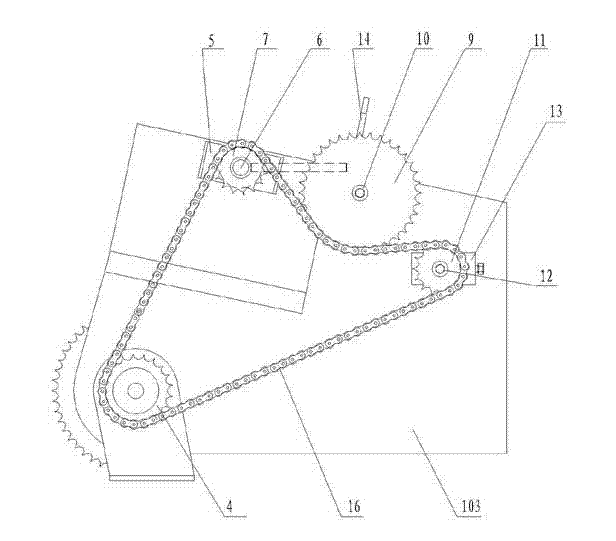

[0010] exist figure 1 , figure 2 Among them, a miscellaneous removal device for an ear elevator of a corn harvester, which includes a lifting tank 1, the lifting tank 1 is composed of a bottom plate 101 and a first groove plate 102 and a second groove plate 102 respectively welded and fixed on both sides of the bottom plate 101. Two groove plates 103 are formed.

[0011] Such as figure 1 As shown, a driving shaft 2 is rotatably assembled on the first slot plate 102 and the second slot plate 103 at the entry end of the lifting slot 1 . A driving sprocket 3 is keyed on the shaft end of the drive shaft 2 protruding from the outside of the first slot plate 102 . exist figure 1 , figure 2 Among them, a power output sprocket 4 is keyed on the shaft end of the driving shaft 2 protruding from the outside of the second slot plate 103 .

[0012] exist figure 1 , figure 2 Among them, a mounting bracket 5 is welded and fixed on the outer rear upper side of the second slot plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com