Pneumatic torque pulse wrench with step-by-step shutoff

A technology of pulse wrench and pneumatic torque, which is used to measure torque/torsion force, motor tools and other directions during wrench and tightening, and can solve problems such as overshoot and too strong pulse torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

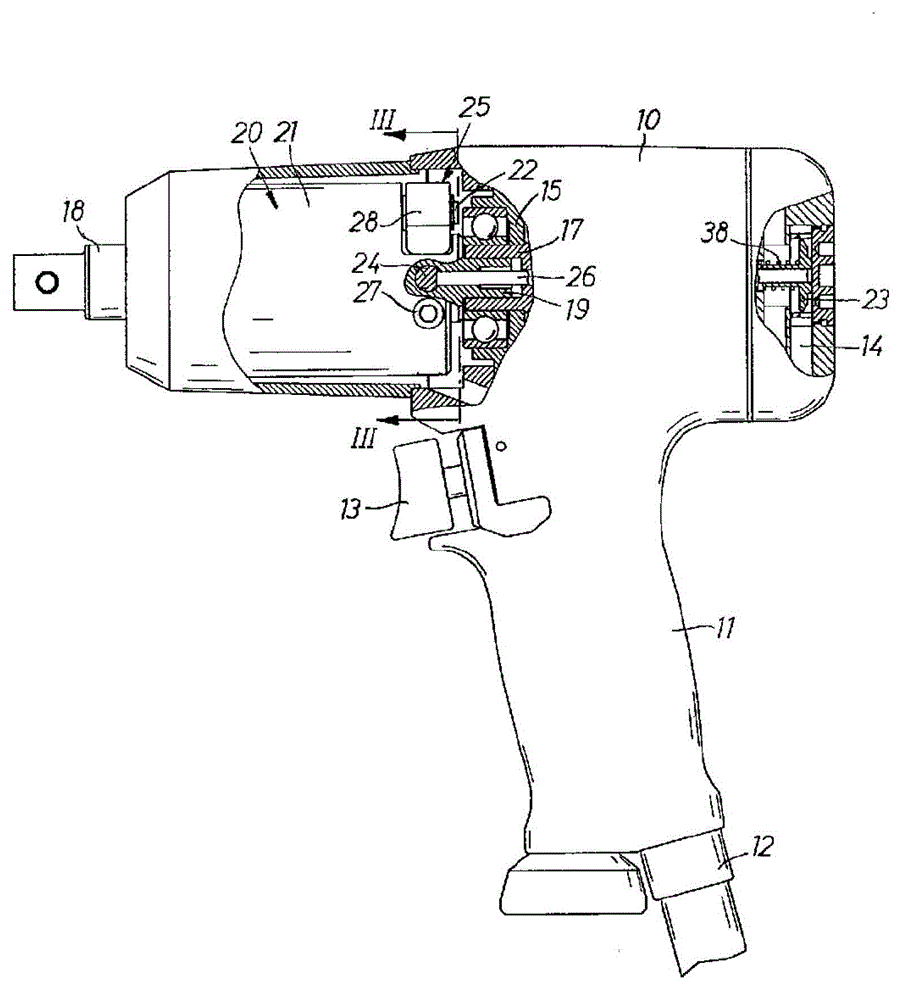

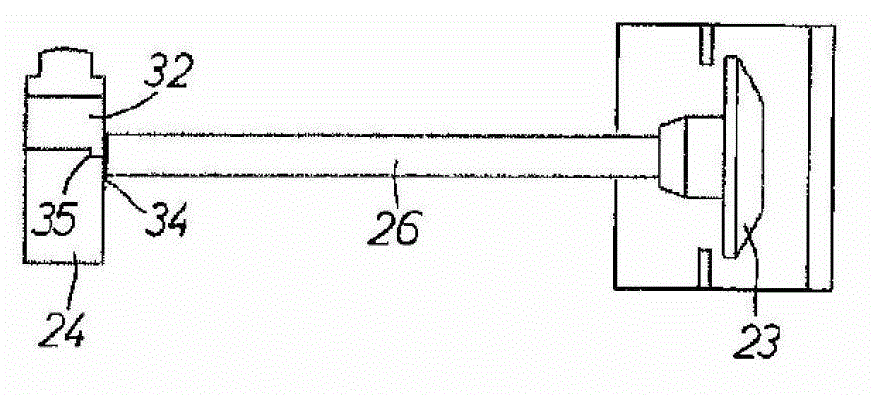

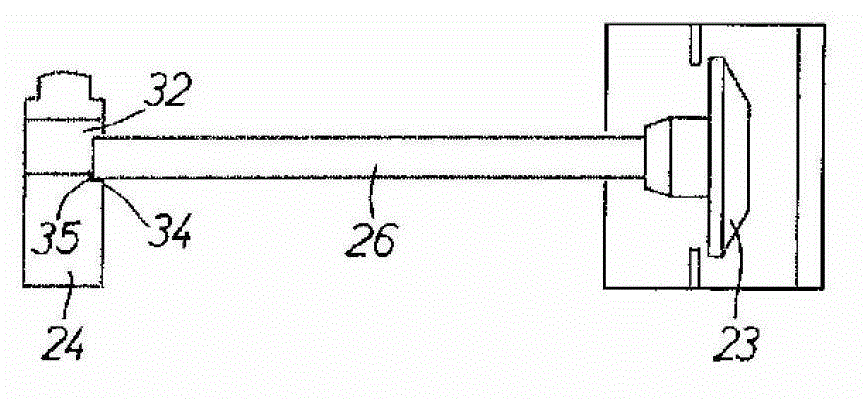

[0020] The power wrench shown in the figures is a pistol-type air pulse wrench comprising a housing 10 with a handle 11 . The handle 11 is provided with a connection 12 for a compressed air line and comprises a throttle valve operated by a trigger 13 . The throttle valve is arranged to control the supply of compressed air through a compressed air supply channel 14 in the housing 10 , which communicates with the air motor 15 . The motor 15 comprises a rotor 17 connected to a square-ended output shaft 18 via a hydraulic pulse unit 20 . The output shaft 18 is intended to carry a nut socket for connection to a threaded joint so that it is fastened. The pulse unit 20 includes an inertial drive member 21 having a rear extension 19 coupled to the motor rotor 17 . In a well-known manner, the inertial drive member 21 also includes an internal fluid chamber into which the rear end of the output shaft 18 extends, wherein the inertial drive member 21 is intermittently coupled to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com