Element mounting device and input management method thereof

A management method, a technique for installation, applied in the direction of electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

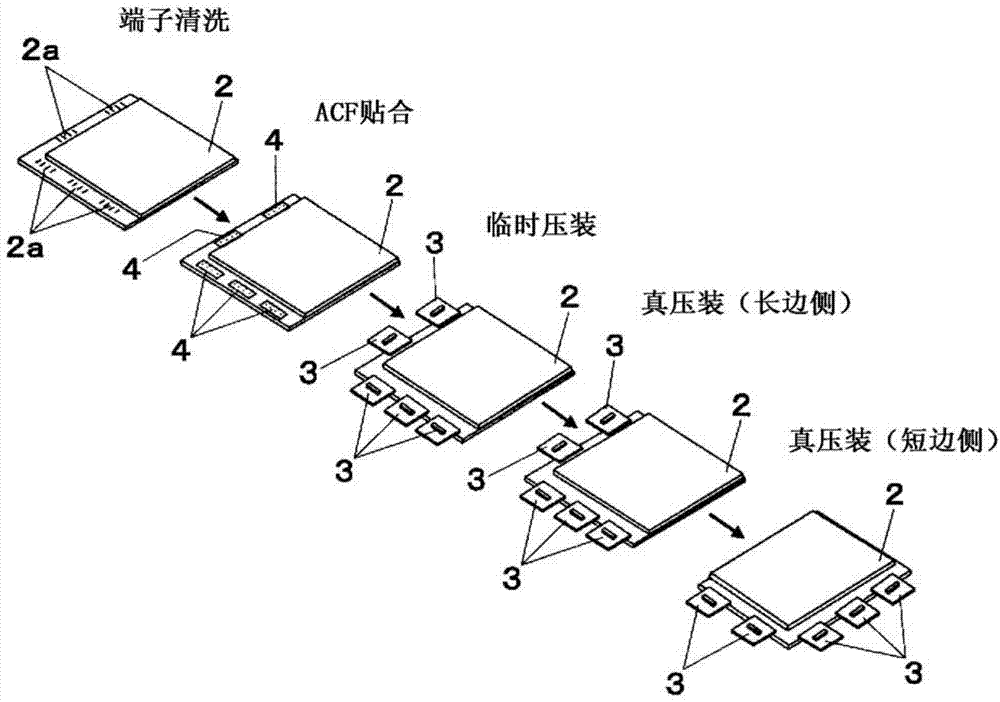

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 The module manufacturing line 1 of the liquid crystal panel shown is to install electronic components 3 such as drive circuits to the multiple terminals 2a provided at the respective ends of the long and short sides of a rectangular panel 2 as a substrate (also refer to figure 2 ) Module manufacturing process, the terminal cleaning device 11, the ACF bonding device 12, the temporary press fitting device 13, two true press fitting devices 14 (the first true press fitting device 14a and the second true press fitting device 14b) and inspection The devices 15 are connected in sequence. These devices 11, 12, 13, 14a, 14b, and 15 operate under the unified control of the host computer 16. When a production command is issued from the host computer 16, the above-mentioned devices 11, 12, 13, 14a, 14b, and 15 respectively execute the module manufacturing process. Each respo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com