Speed changer used for tractor

A transmission and tractor technology, applied in mechanical equipment, transmission parts, gear transmissions, etc., can solve the problems of high gear speed and transmission noise, and achieve the effect of increasing transmission torque and improving sports performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

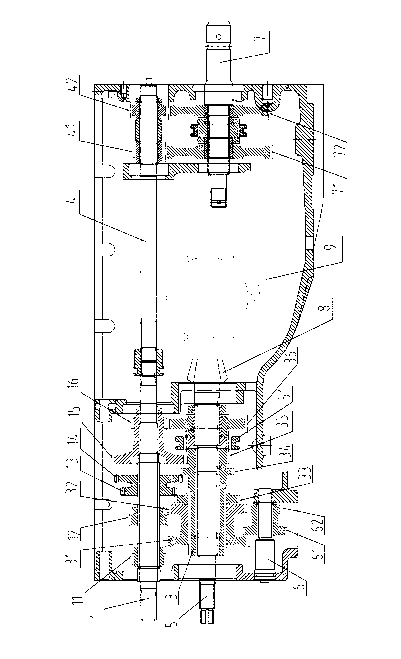

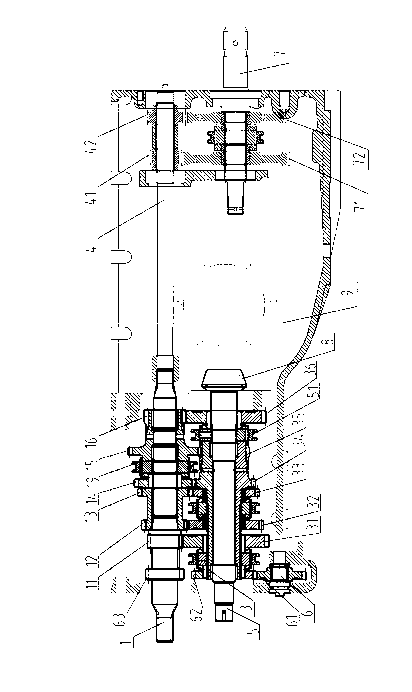

[0015] figure 1 It is the first embodiment of the present invention. This embodiment will be described in detail in conjunction with the accompanying drawings, including shaft I1, shaft III3, shaft IV4, shaft V5, shaft VI6, shaft VII7, first-speed main gear 11, and first-speed pinion gear 31 , second gear main gear 12, second gear auxiliary gear 32, third gear main gear 13, third gear auxiliary gear 33, fourth gear main gear 14, fourth gear auxiliary gear 34, high speed double gear 15, low speed double gear 16, high speed Gear 35, low gear 36, transmission gear Ⅰ41, transmission gear Ⅱ42, gear gear Ⅰ71, gear gear Ⅱ72, reverse gear Ⅰ61, reverse gear Ⅱ62, bevel gear Ⅰ8, bevel gear Ⅱ9, high and low gear meshing sleeve 51, shaft The center line of I1 and the center line of shaft IV4 are set on the same straight line, the shaft III3 is set to be sleeved on the shaft V5 and set to be rotationally connected with the shaft V5, the shaft I1 is set to be connected to the output shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com