Packing box

A packaging box and box cover technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of waste of resources, high production costs, large storage space, etc., and achieve the advantages of diverse combinations, enhanced fastening, and simple packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

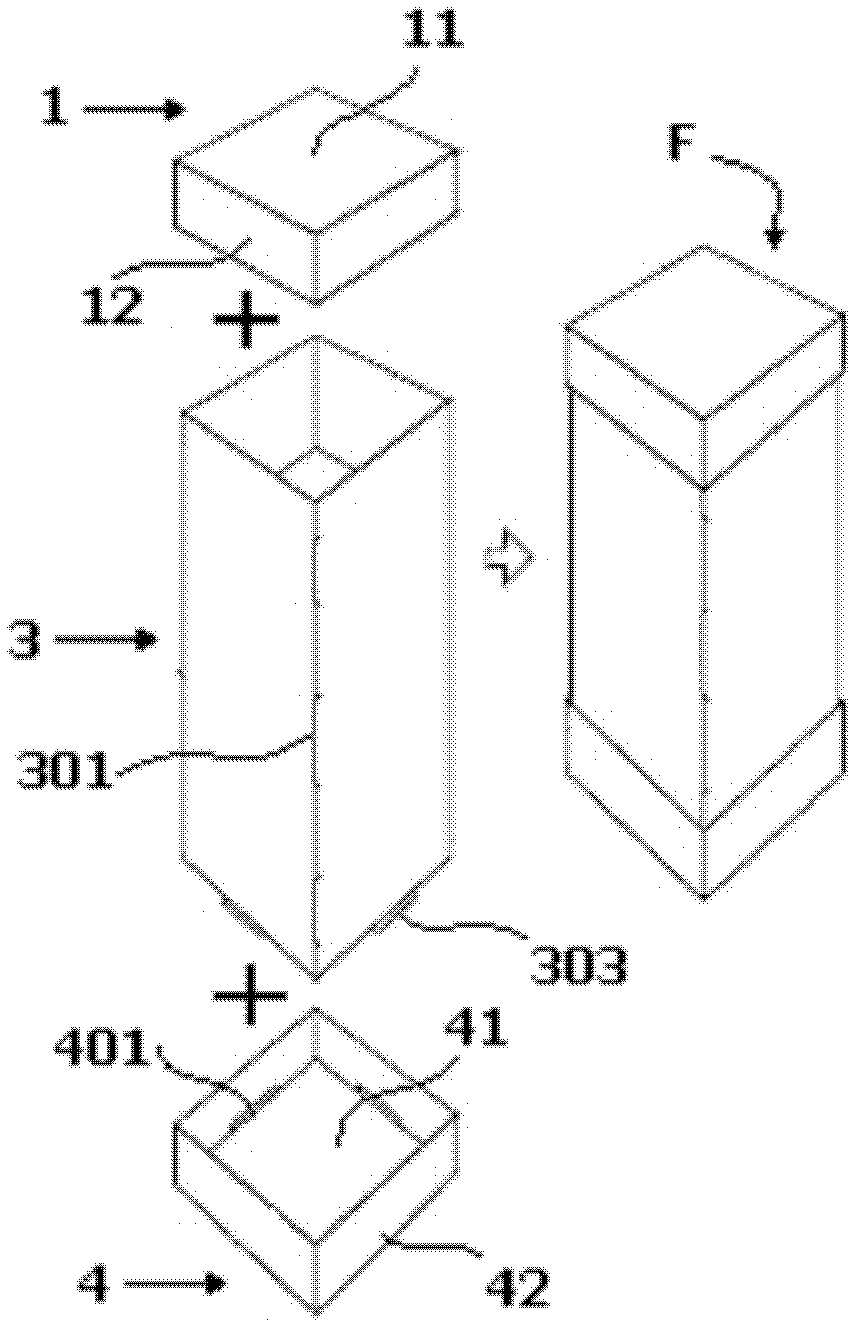

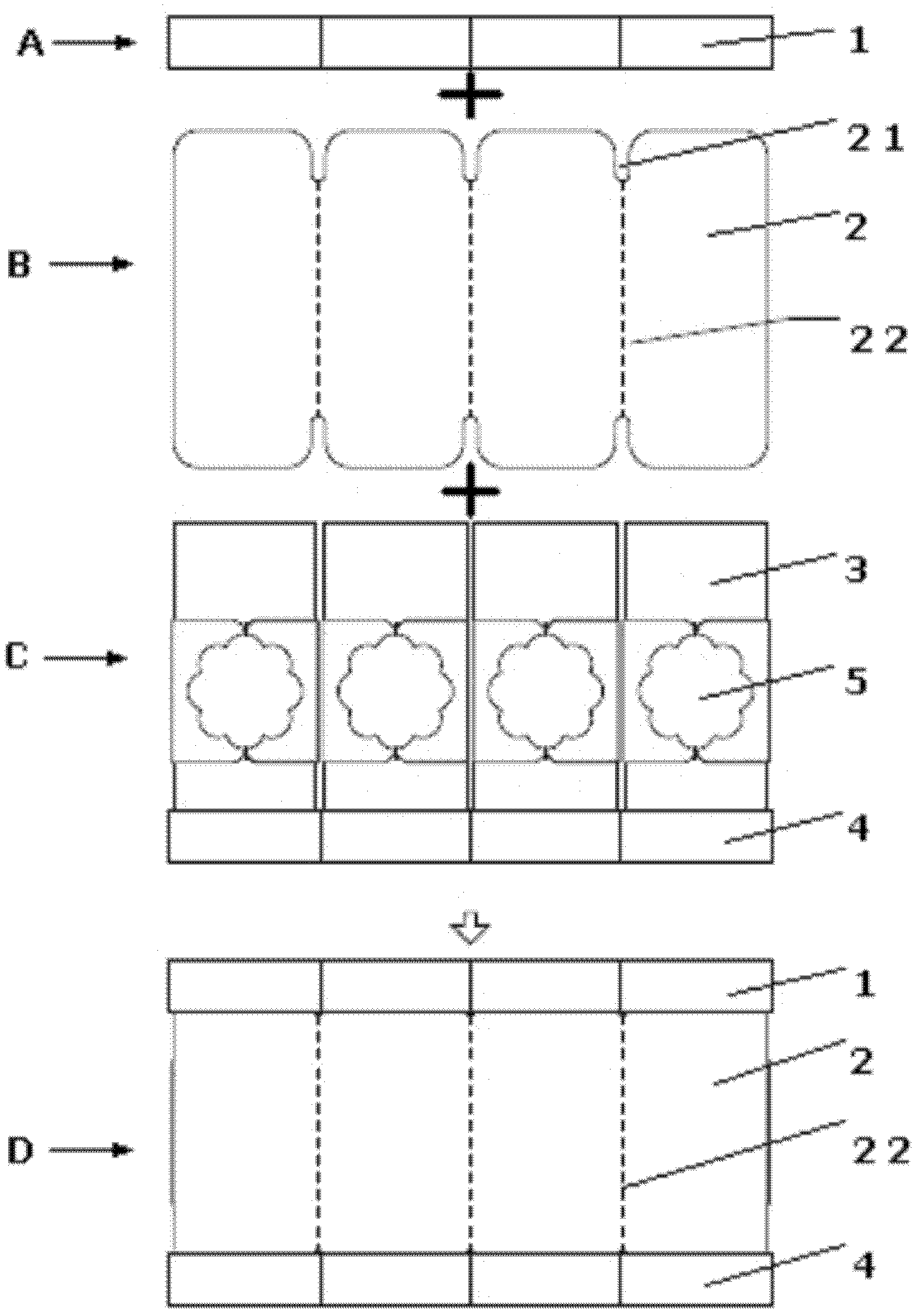

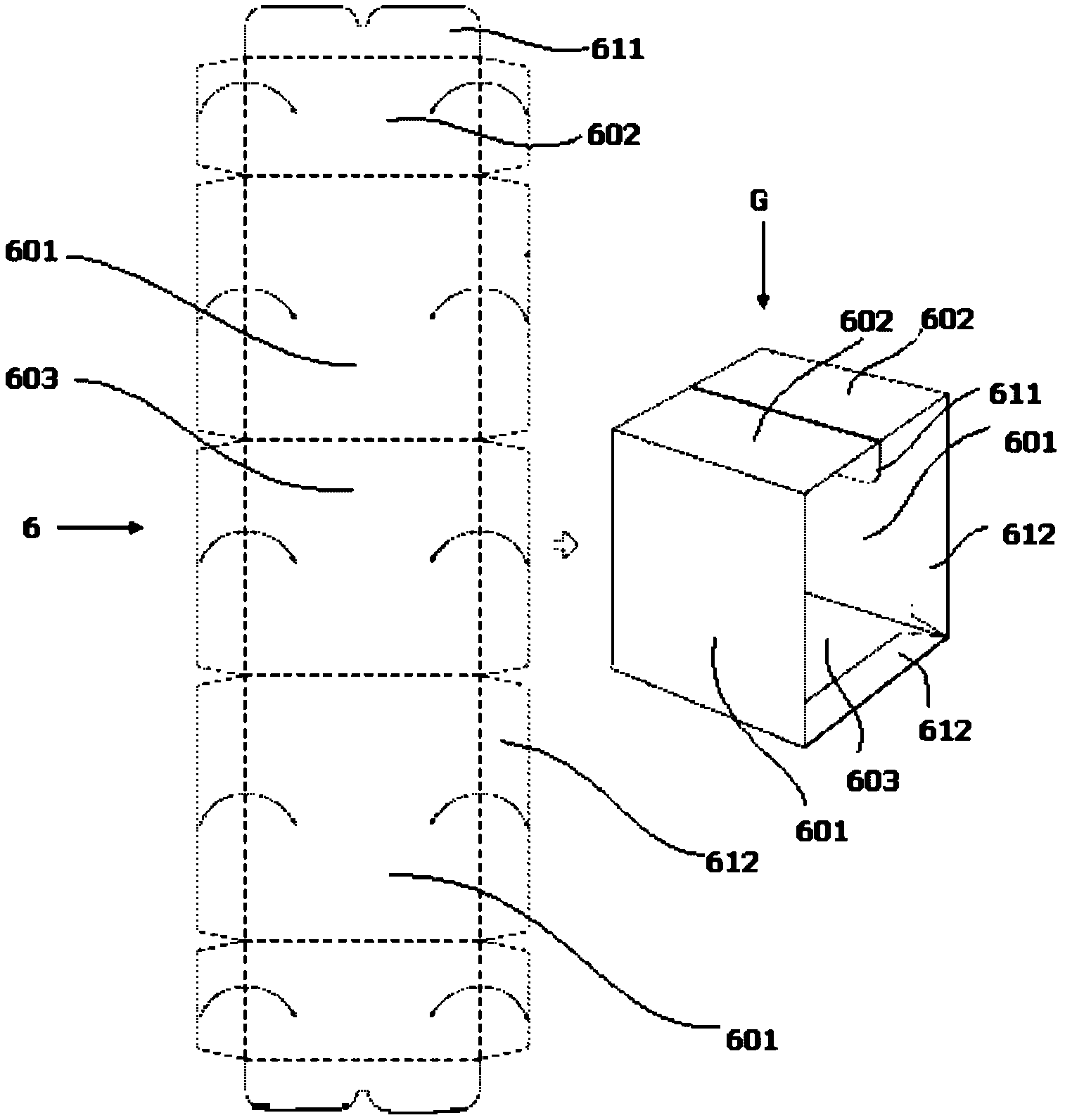

[0037] combine figure 1 , figure 1 It is a schematic diagram of the structure of the box body of the packaging box of the present invention. As shown in the figure, the packaging box includes a box body F composed of an upper box cover 1, a lower box cover 4 and a box body 3; wherein the upper box cover 1 is formed by cutting and folding a plane plate , including a bottom plate 11 and four side plates 12, and there are card slots 101 at the joints of the inner bottom plate of the box cover and the four side plates; the lower box cover 4 is formed by cutting and folding a flat plate, including a bottom plate 41 and four side plates 42. There are card slots 401 at the joints of the inner bottom plate and the four side plates of the box cover; the box body 3 is formed by cutting and folding a flat plate, and the joint of the box body after folding is connected by a card slot 301 and a card 302. At the connection between the four side walls 310 of the box body and the lower box c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com