Handheld barcode terminal

An inventory machine and quality measurement technology, applied in the field of medical device manufacturing, can solve the problems of inventory machine accuracy deviation, high cost, and affecting the reliability of inventory results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

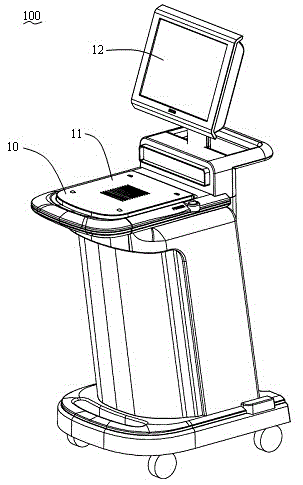

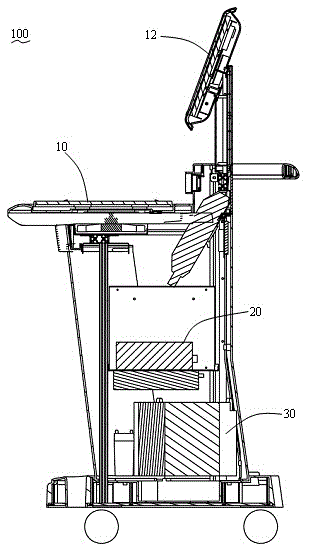

[0020] ginseng figure 1 and figure 2 , to introduce a specific implementation of the inventory machine 100 of the present invention. In this embodiment, the inventory machine 100 includes a main body (not marked), a quality measurement component 10 , a data processing module (not shown), and a control component 20 .

[0021] The main body defines the overall appearance of the inventory machine 100. The mass measurement component 10 is at least partly disposed on the main body, and it is used to measure the weight of the medicines to be counted. Load-bearing panels11. As is well known to those skill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com