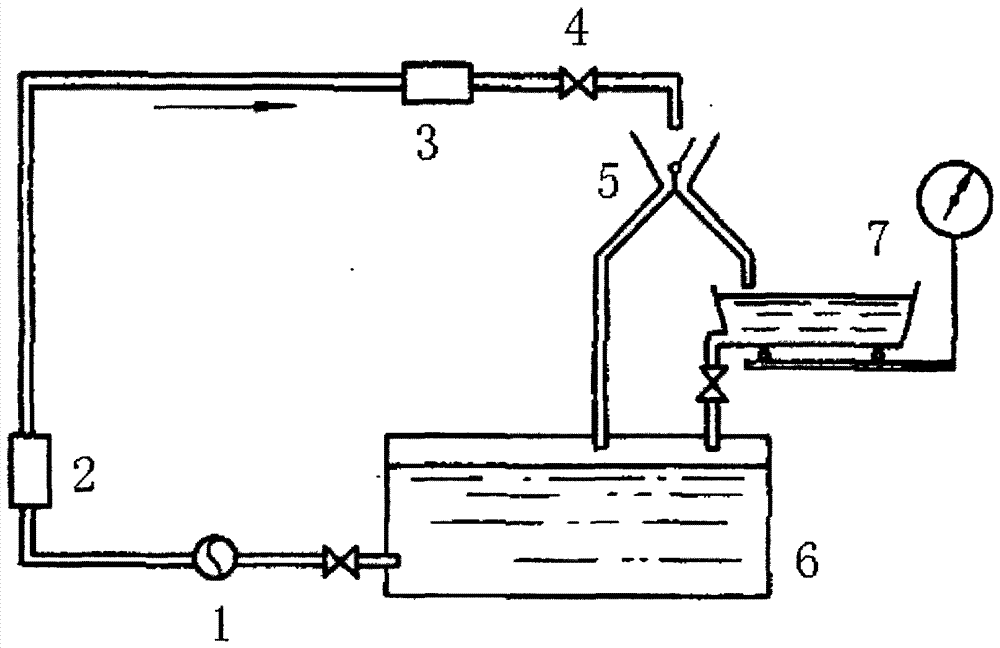

High Precision Weighing System in Flow Standard Units

A weighing system and high-precision technology, applied in the field of weighing systems, can solve the problems of complex installation, large height space, and platform stability affecting the accurate measurement of electronic scales, and achieve the advantages of maintaining air buoyancy, avoiding interference, and favorable stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

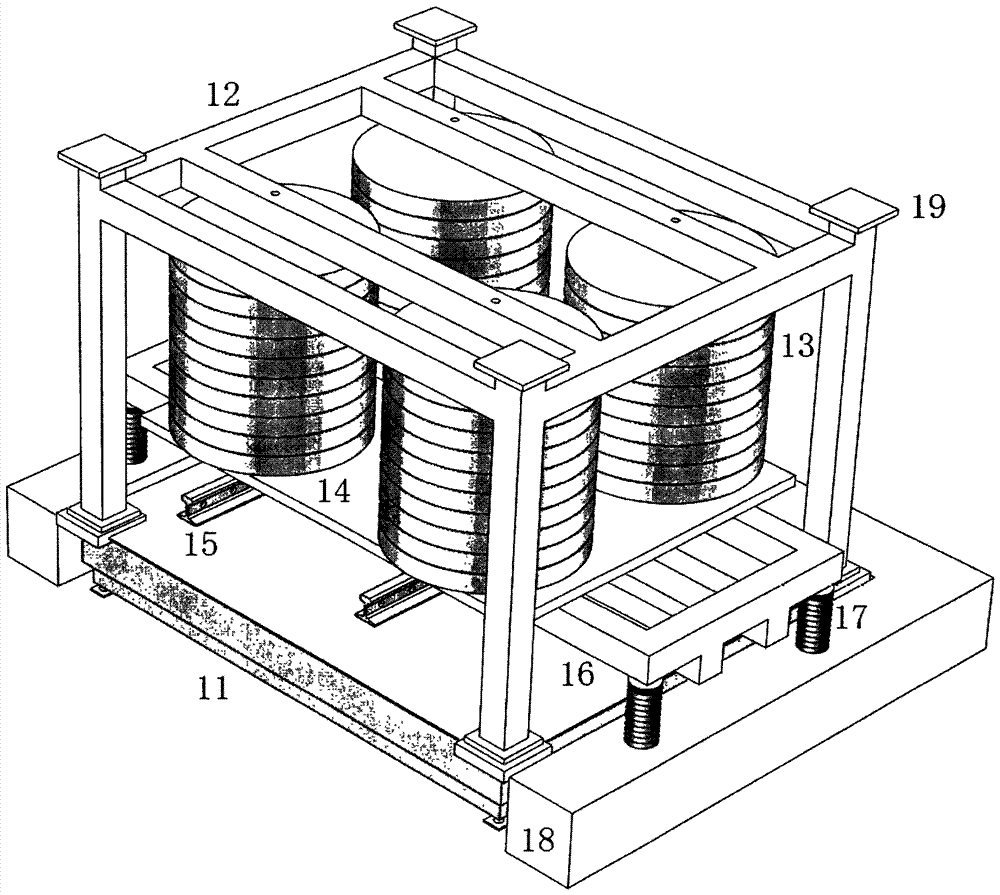

[0017] Reference will be made in detail below to exemplary embodiments of the invention shown in the accompanying drawings. The accompanying drawings are only for the convenience of understanding the invention, and their specific schematic structures, proportions, dimensions and specific line forms are not intended to limit the invention. It needs to be declared that what is given in the embodiment is a schematic structure of the present invention, and is not intended as a limitation to the specific structure.

[0018] Such as figure 2 Shown is a schematic structural diagram of the high-precision weighing system in the flow standard device of the present invention. The weighing system includes: electronic scale 11 , hanging weight frame 12 , weight group 13 , weight platform 14 , guide rail 15 , lifting frame platform 16 , lifting rod 17 and transmission assembly 18 .

[0019] Described electronic scale 11 is positioned at the bottom of weighing system, and it can be positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com