Back plate wall built-up structure of electronic system

An electronic system and wall structure technology, applied in the direction of electrical digital data processing, digital processing power distribution, instruments, etc., can solve the problems of labor-intensive and inconvenient, cost-intensive, maintenance personnel spending more time and manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

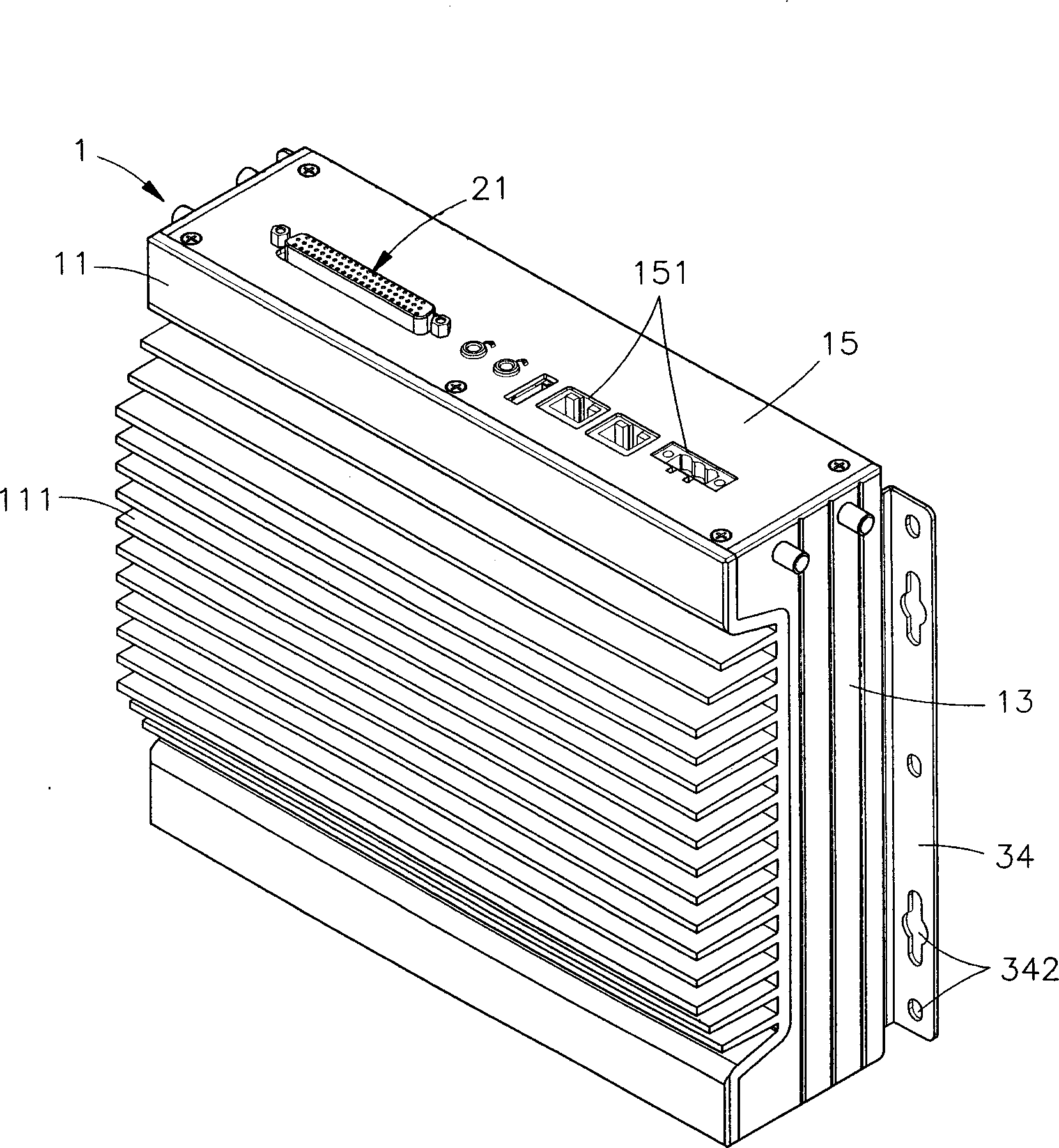

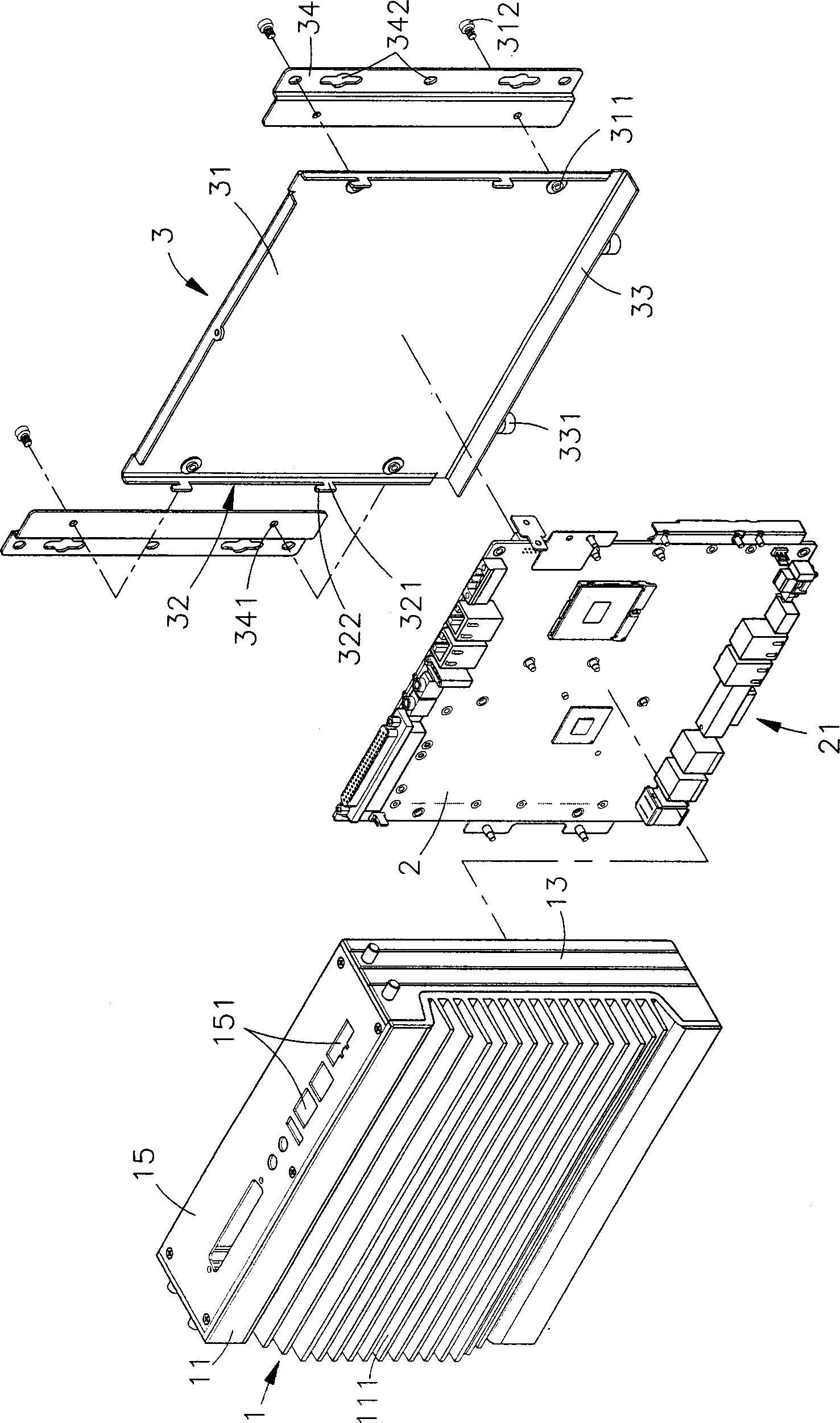

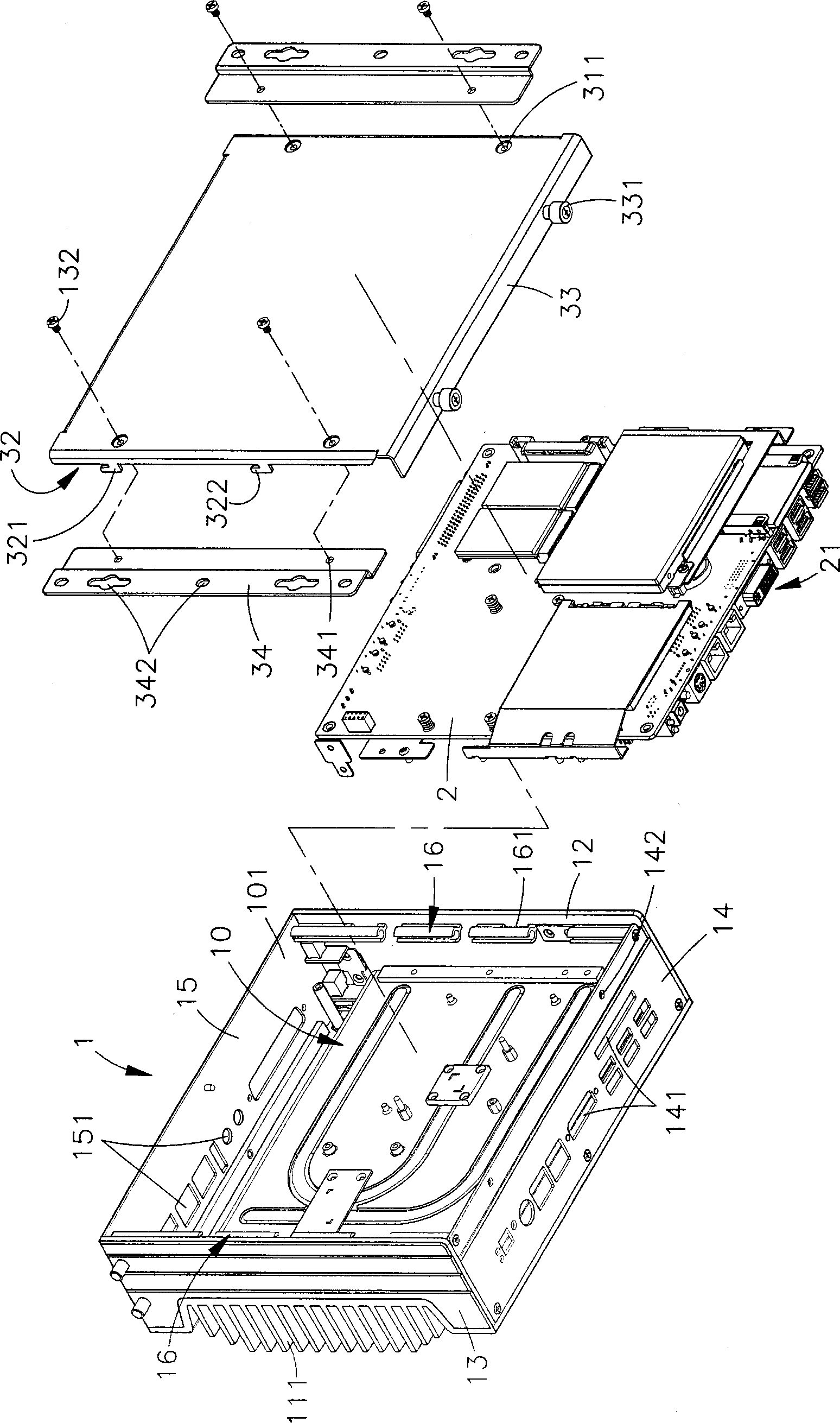

[0018] see figure 1 , figure 2 , image 3 As shown, they are respectively a three-dimensional appearance view, a three-dimensional exploded view and a three-dimensional exploded view from another perspective of the present invention. It can be clearly seen from the figure that the present invention includes an organic casing 1, a circuit board 2 and a back cover 3. , so the main components and features of this case are described in detail below, among which:

[0019] The casing 1 has a front casing 11, and opposite casing casings 12, 13 are provided on both sides of the front casing 11 in the same direction, and the upper and lower sides of the two casing casings 12, 13 face the front casing. The opposite bottom shell 14 and upper cover 15 are provided extending in the direction of the body 11, thereby forming an accommodating space 10 with an opening 101 inside the shell 1; in addition, the two outer shells 12, 13 of the shell 1 are opposite A sliding portion 16 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com