Multipoint sampling device for fermented grains of white spirits and application method thereof

A technology of sampler and distiller's grains, applied in the direction of sampling devices, etc., can solve the problems of time-consuming and laborious, difficult to clean, and uncertain sampling volume, etc., and achieve the effect of improving sampling efficiency, reducing intensity, and reducing the number of sampling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

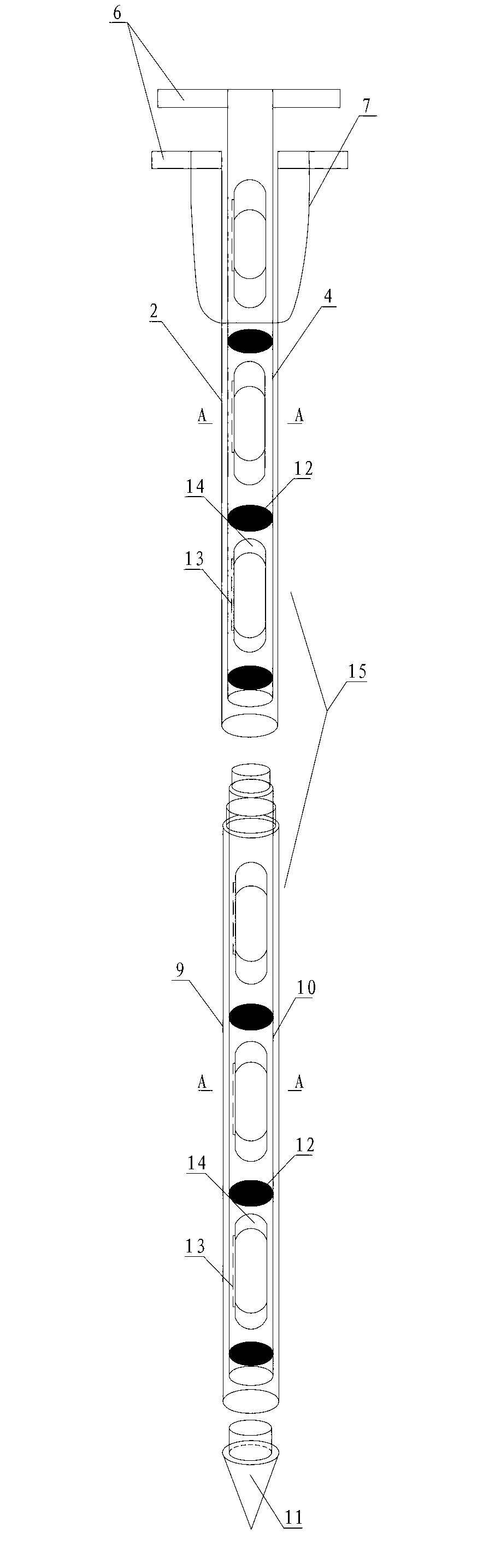

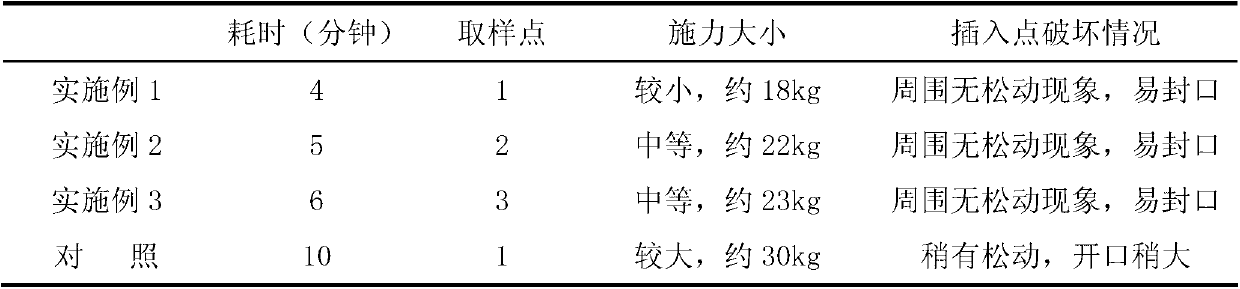

[0028] Embodiment 1 Using the method of the present invention and a multi-point sampler to sample the distiller's grains in the fermentation cellar of distiller's grains at one sampling point, the operation process is as follows,

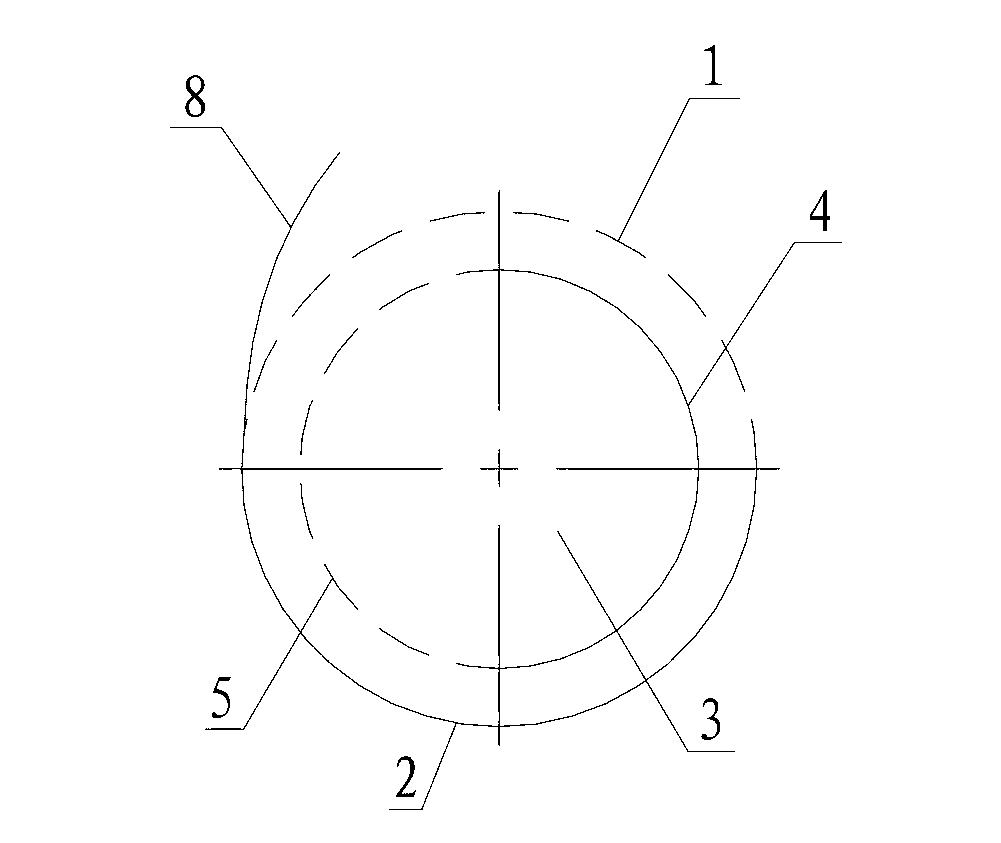

[0029] a. The depth of the cellar is 1.7m, and the multi-point sampler composed of the inner casing 4 and the outer casing 2 is selected;

[0030] B, the inner casing 4 of described multipoint sampler is packed in the outer casing 2, forms the multipoint sampler of described structure;

[0031] c. Insert the sealing insert 14 of the sampling opening into the socket 13 to close the upper and middle sampling chamber opening 5 of the outer casing 2, leaving only the bottom sampling chamber opening 5 open;

[0032] d. Completely insert the assembled multi-point sampler 15 into the distiller's grains fermented cellar, hold the handle 6 of the outer sleeve 2 and keep it still, then hold the inner sleeve 4 and rotate it 180° clockwise, and hold the inner s...

Embodiment 2

[0034] Embodiment 2 Using the method of the present invention and a multi-point sampler to sample the distiller's grains in the fermentation cellar of distiller's grains at two sampling points, the operation process is as follows,

[0035] a, cellar depth is 2.4m, select described multi-point sampler inner casing 4, outer casing 2, auxiliary inner casing 10, auxiliary outer casing 9 and conical head 11;

[0036] b. Connect the inner sleeve 4 of the multi-point sampler with the auxiliary inner sleeve 10, the outer sleeve 2 with the auxiliary outer sleeve 9, and the auxiliary outer sleeve 9 with the conical head 11, and connect them from top to bottom The inner casing assembly is loaded into the outer casing assembly;

[0037] C, the sampling opening closing insert 14 is inserted in the socket 13, the middle and upper part sampling bin opening 5 of sealing outer casing 2 and auxiliary outer casing 9, only the bottom sampling bin opening 5 of outer casing 2 and auxiliary outer ca...

Embodiment 3

[0040] Embodiment 3 Using the method of the present invention and a multi-point sampler to sample the distiller's grains in the fermentation cellar of distiller's grains at three sampling points, the operation process is as follows,

[0041] A, cellar pool depth is 3m, select described multi-point sampler inner casing 4, outer casing 2, two-section auxiliary outer casing 9, two-section auxiliary inner casing 10 and conical head 11;

[0042] b. Connect the outer casing 2 of the multi-point sampler with the auxiliary outer casing 9 of each section, connect the inner casing 4 with the auxiliary outer casing 10 of each section, and put the inner casing assembly into the outer casing from top to bottom In the tube assembly, connect the bottom section of the secondary outer tube to the conical head;

[0043] C, the sampling opening closing insert 14 is inserted in the socket 13, the middle and upper part sampling bin opening 5 of sealing outer casing 2 and auxiliary outer casing 9, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com