Multi-crankshaft concrete mixer

A mixer and concrete technology, used in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as unbalanced operation, affecting the normal operation of mixers, easily causing vibration, etc., to achieve accelerated mixing and high-quality mixing. effect, the effect of increasing the stirring frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

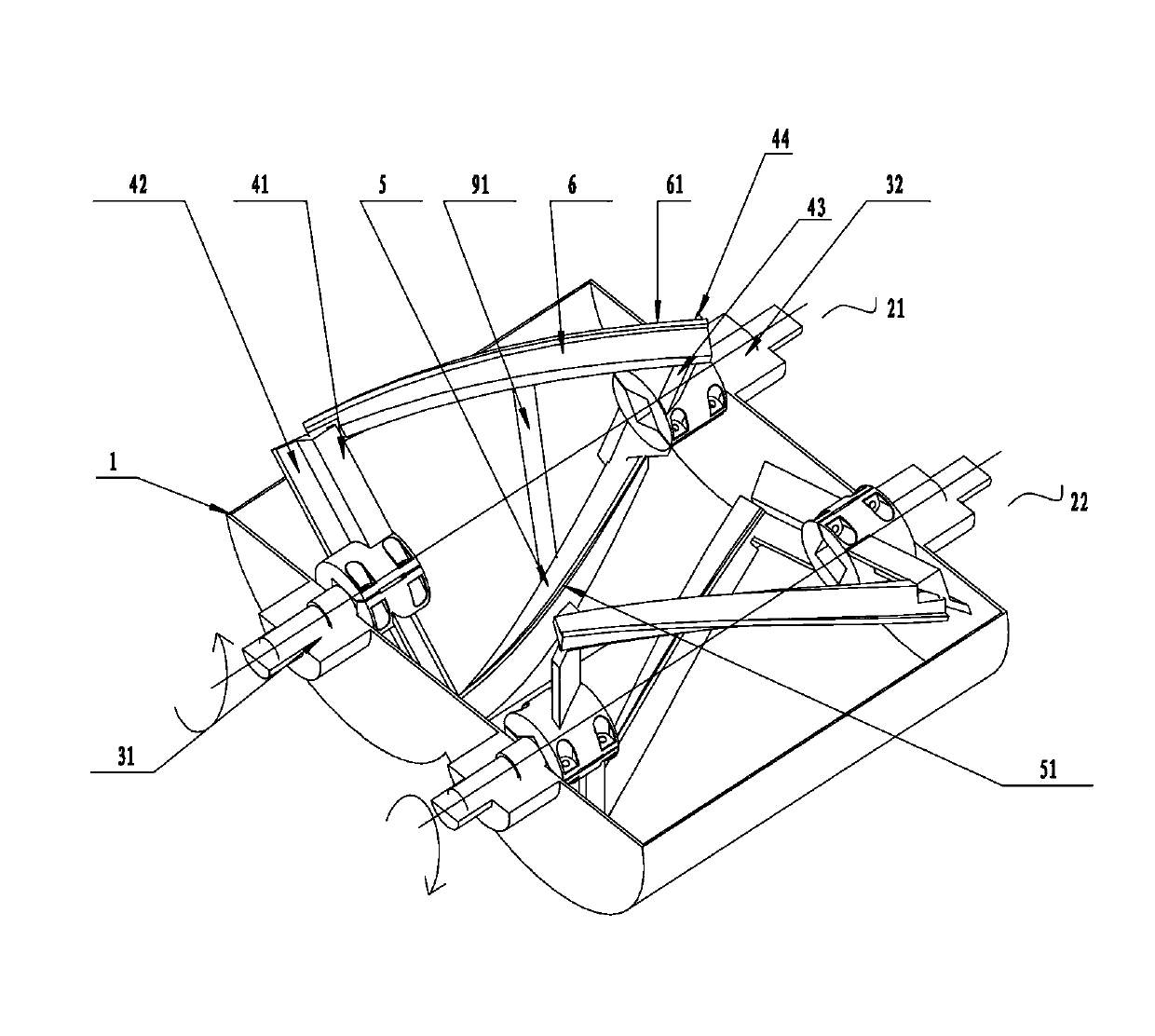

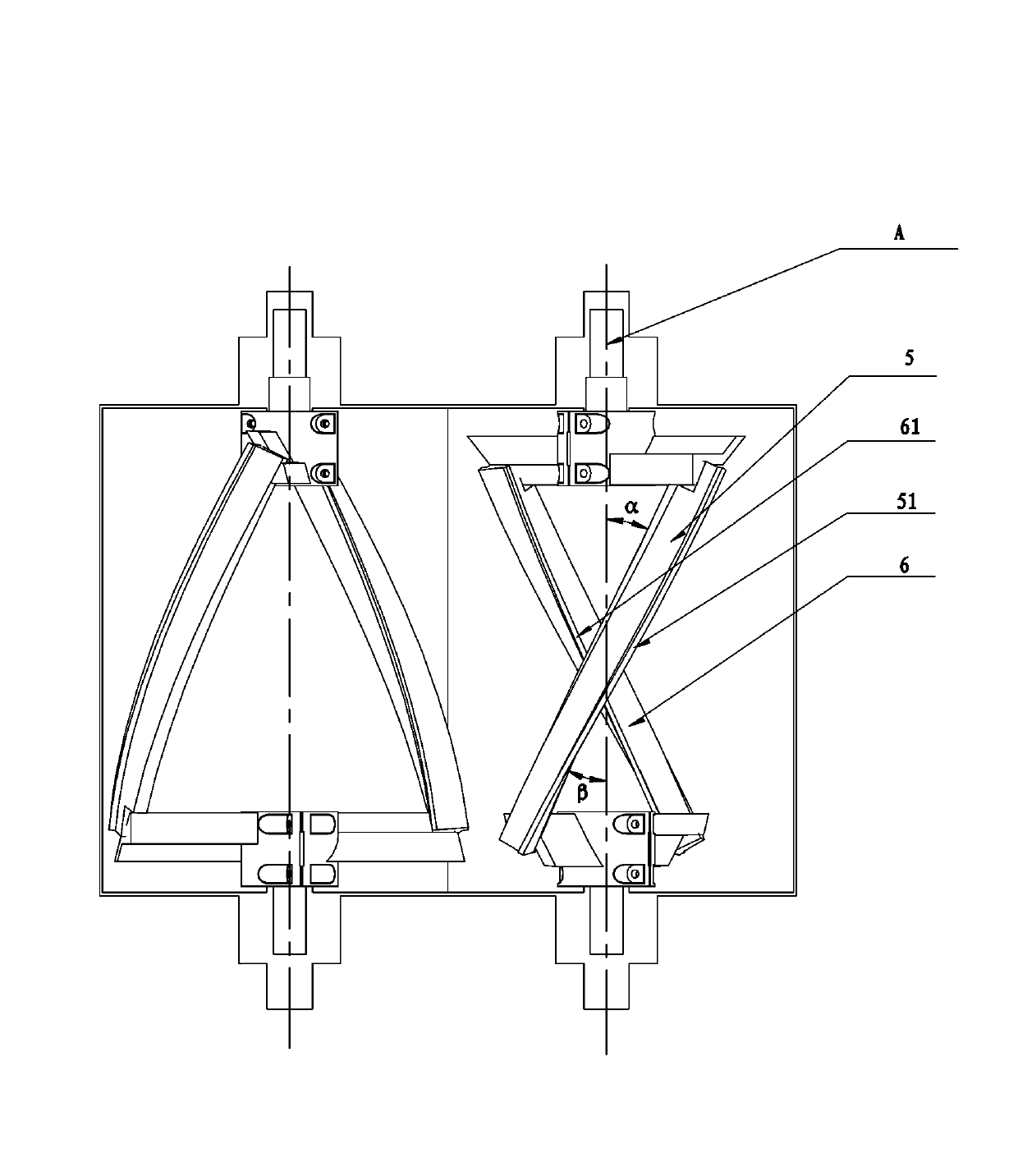

[0029] Such as figure 1 Shown is a multi-crankshaft concrete mixer, which includes more than one mixing device rotatably connected in the mixing drum 1 . Each agitator includes a side feed assembly, a side return assembly and an agitation crankshaft assembly.

[0030] Wherein, the side feed assembly includes a feed agitating arm 41 connected to the drive shaft end 31 of the agitator, and the feed agitating arm 41 is integrally or separately provided with a side feed blade 42 . The side return assembly includes a return stirring arm 43 connected to the driven shaft end 32 of the mixer. The return stirring arm 43 is integrally or separately provided with a side return blade 44 . The side feed vane 42 and the side return vane 44 provided separately are detachable structures for easy replacement. The side feed blade 42 and the side return blade 44 of the present invention are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com