Movable sunlight constant temperature room

A sunlight and constant temperature technology, applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of high cost, large heat energy required for heating, poor heat preservation effect, etc., and achieve low cost of constant temperature, high heat utilization rate, and heat preservation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

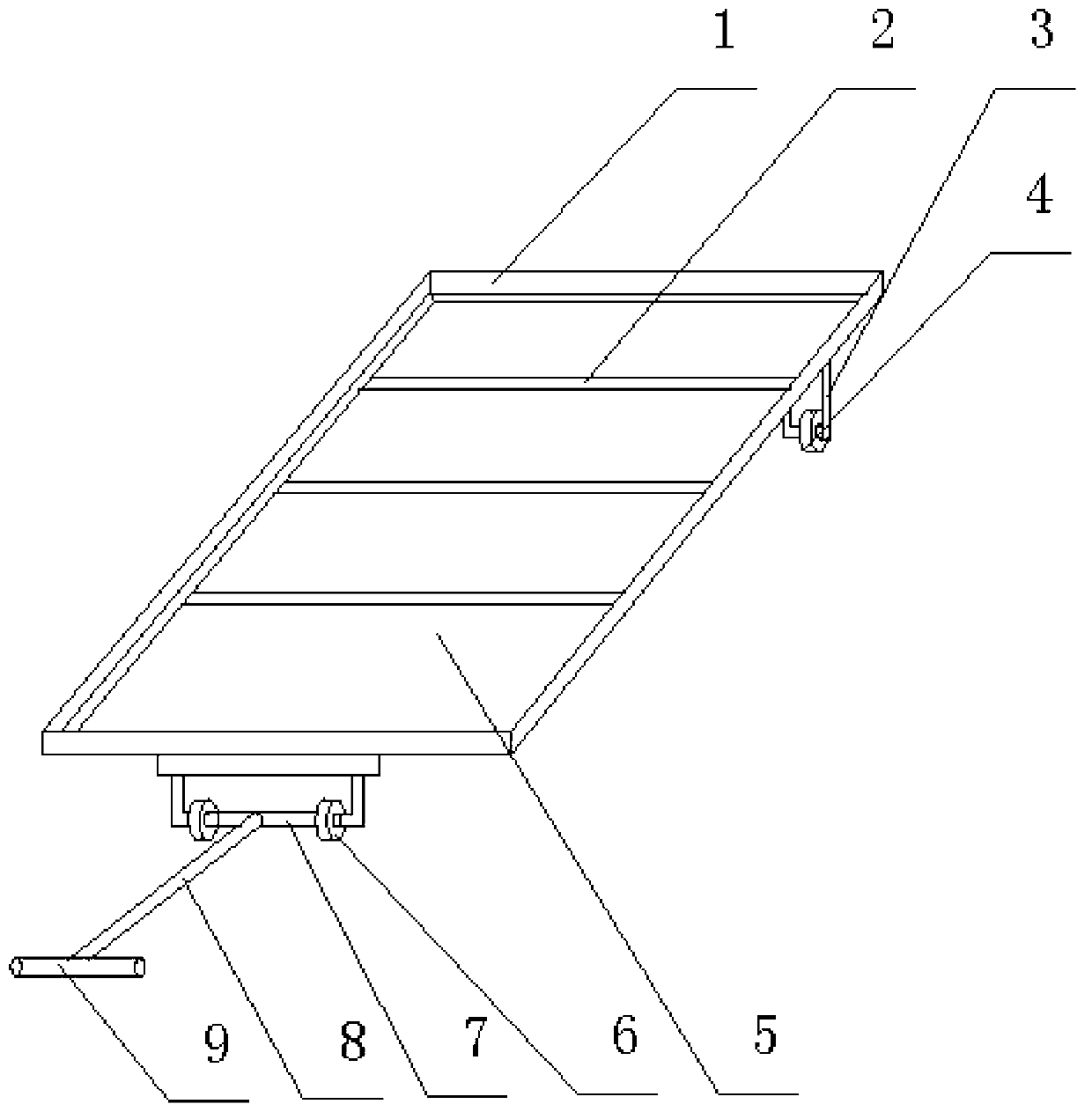

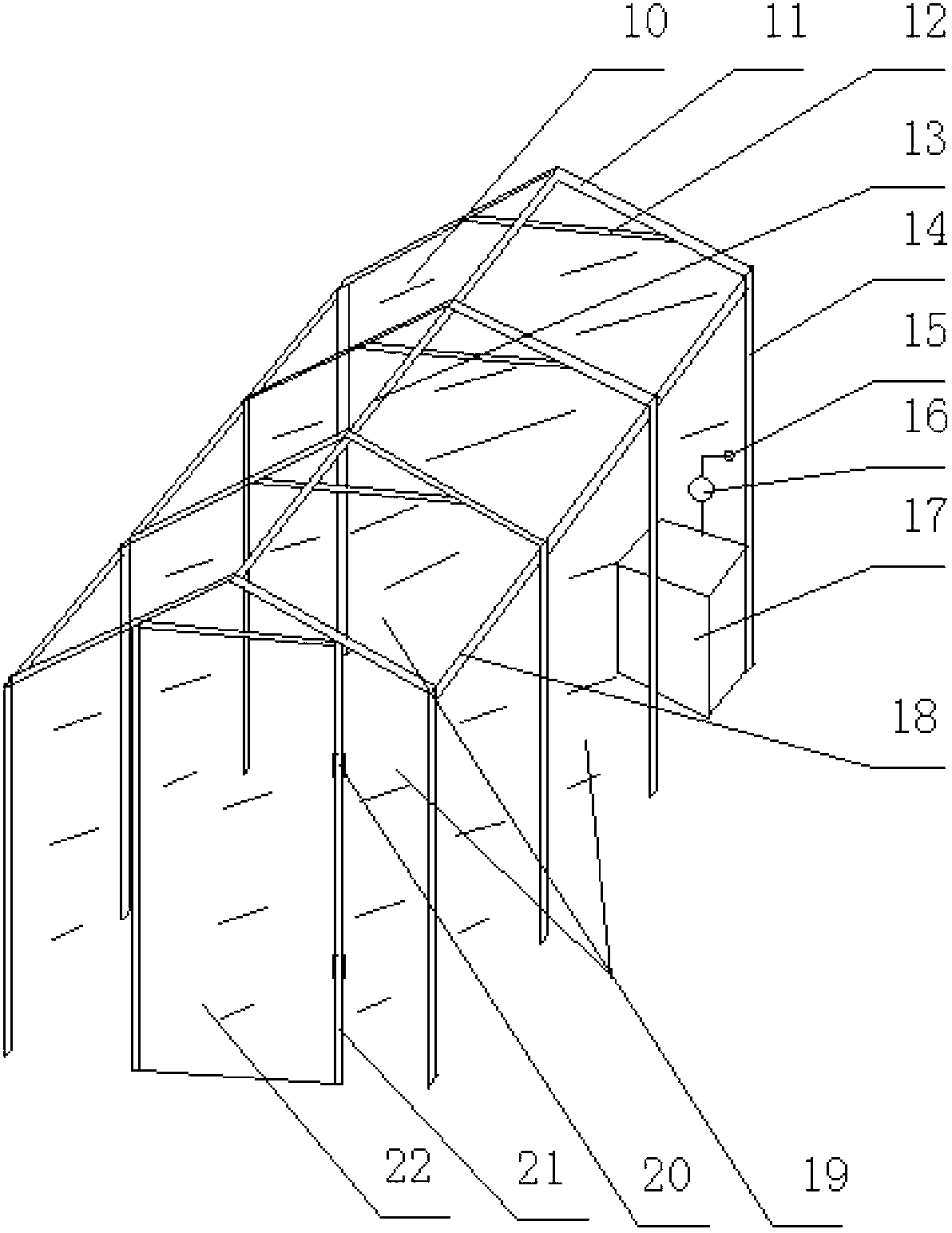

[0018] A mobile sunlight constant temperature room, such as figure 1 Or as shown in 2, it includes a mobile chassis 5 and a sun room 10 welded on the chassis, wherein the mobile chassis further includes a rectangular chassis frame beam 1 welded to it, a reinforced bottom beam 2 for reinforcing the chassis frame beam, and welded on the chassis frame beam 2 respectively. The rear wheel frame 3 under the frame beams on the left and right sides of the frame beam, the left and right rear wheels 4 respectively installed on the two rear wheel frames, the front wheel frame 7 welded under the front side frame beam of the chassis frame beam, and the The two front wheels 6 mounted on the front wheel frame in axial symmetry, the pull rod 8 hinged with the front wheel frame and the handle 9 welded to the pull rod, wherein the sun room further includes at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com