Axial flow fan

A streamlined axial flow fan technology, applied in the field of air conditioners and fluid machinery, can solve the problems of increased air supply noise, environmental noise of air conditioners or ventilation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

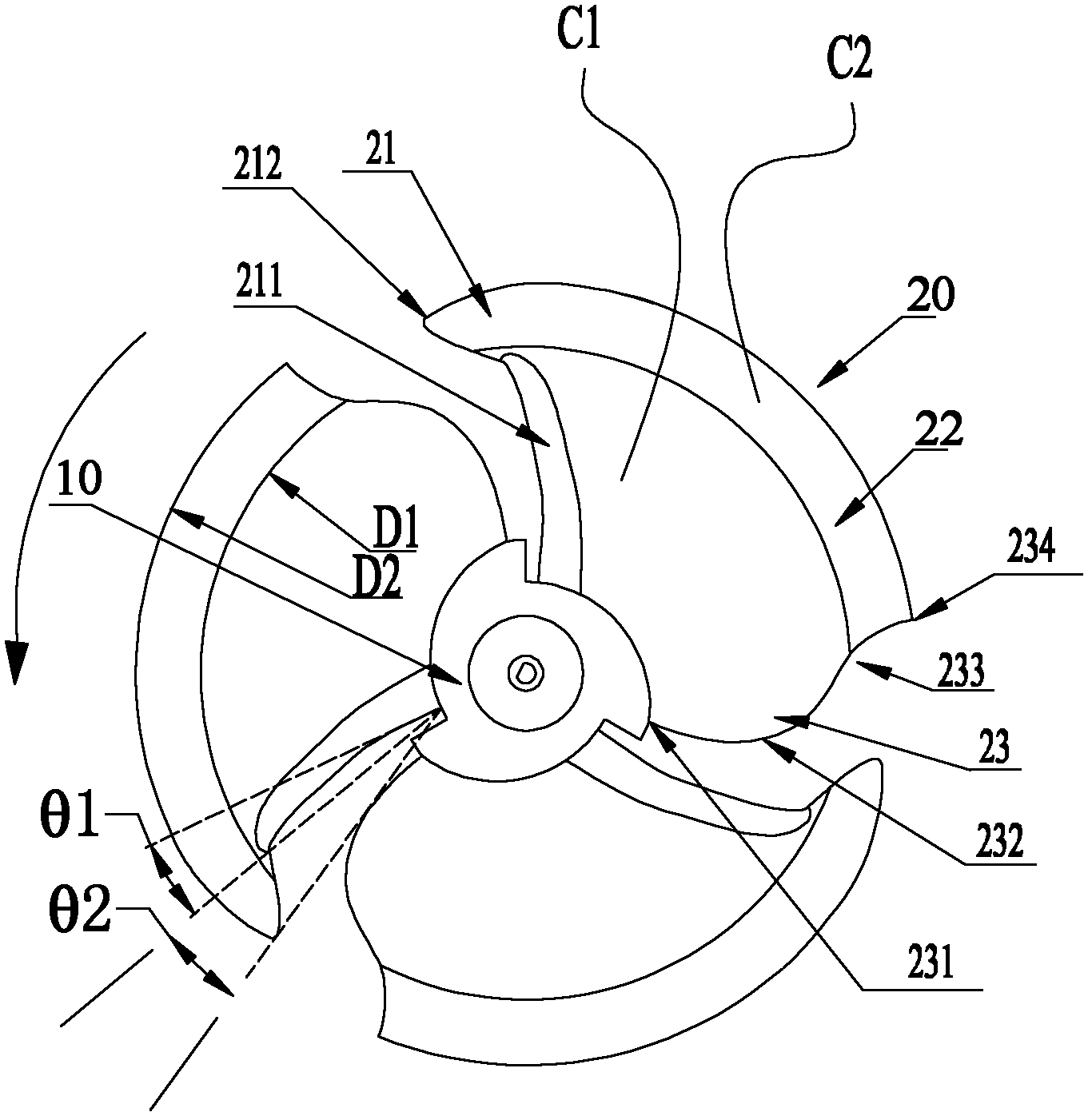

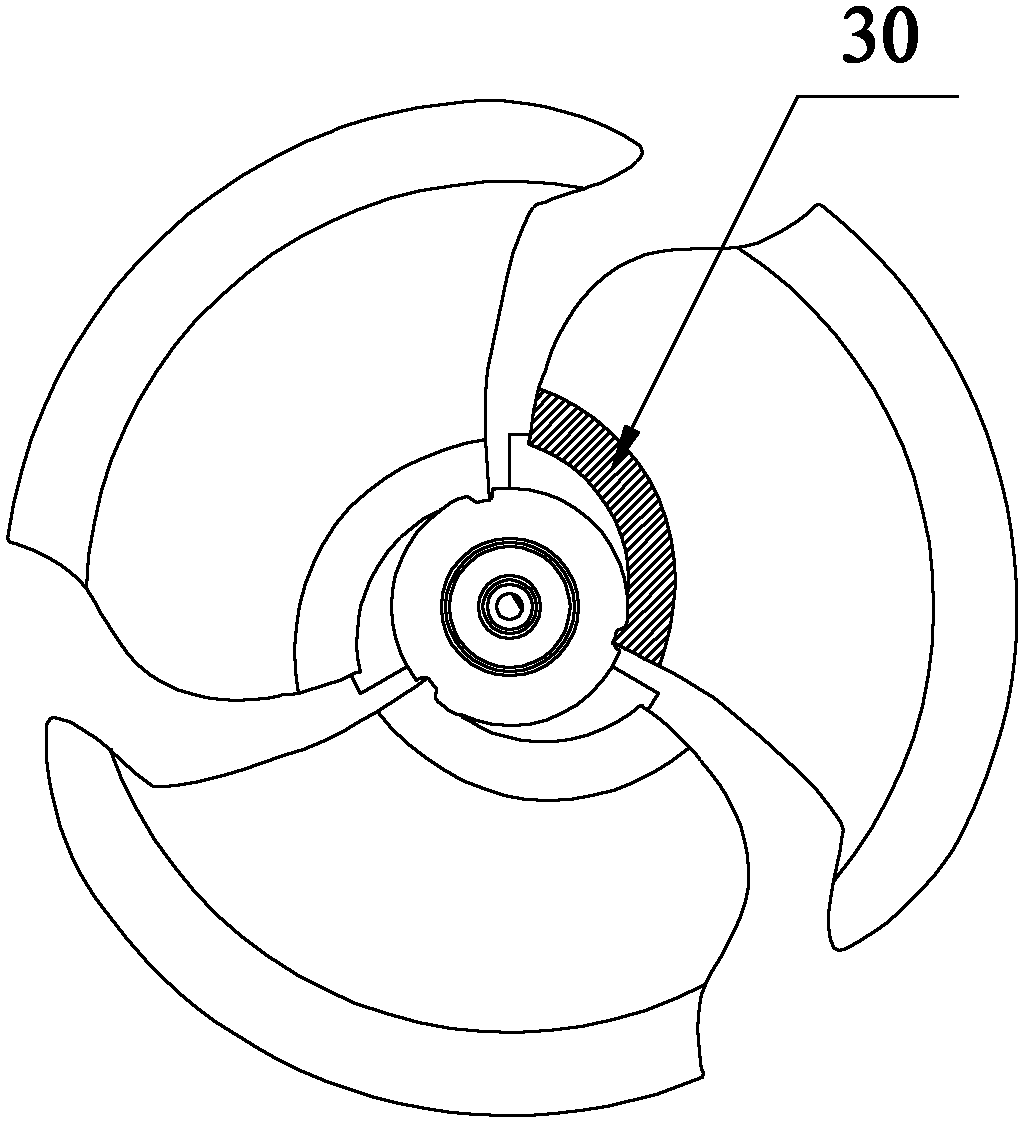

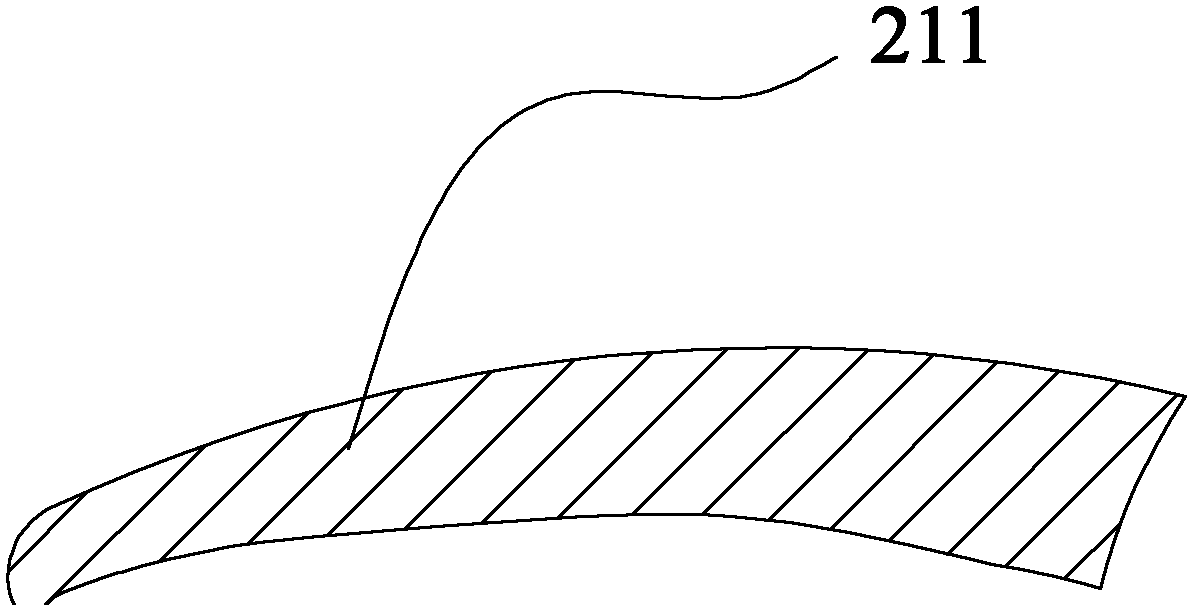

[0035] figure 1 A front view of an axial fan of an embodiment of the present invention is shown. In this example, if figure 1 , Figure 7 As shown, the axial flow fan of the present invention is a three-wing axial flow fan, including a hub 10 as a rotating shaft, and vanes 20 with the same shape that are radially distributed on its outer peripheral side, and the three vanes are arranged at 120° Within the range of ±5°, they are equally spaced or unequally spaced. The front edge of the airfoil 20 is provided with a pressure surface wall thickness reinforced part 211 on the pressure surface side. The thickness of the pressure surface wall thickness reinforced part 211 is thicker than other parts of the airfoil 20. 214 begins to extend along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com