Tool for controlling pouring thickness of concrete floor

A technology of pouring thickness and concrete, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of large errors, low work efficiency, troublesome operation, etc., and achieve the effect of reasonable structure setting, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

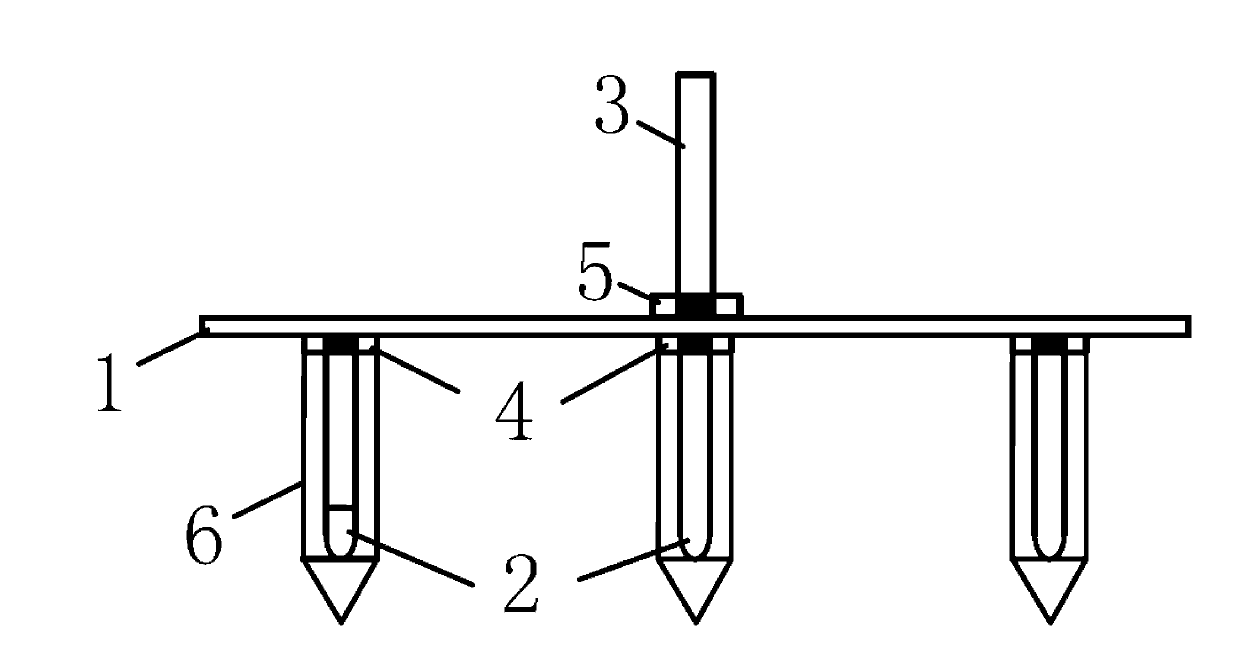

[0015] see figure 1 , figure 2 and image 3 , a tool for controlling the pouring thickness of a concrete floor slab disclosed by the present invention includes a flat plate 1 and a plurality of feet 2 installed at the lower end of the flat plate 1, and a sleeve 6 is sleeved on each foot, and each sleeve 6 The bottom has a conical structure, and the upper end of the flat plate 1 is provided with a pull rod 3 , and the lower end of the pull rod 3 is vertically fixed to the flat plate 1 .

[0016] Preferably, the flat plate 1 described in this embodiment is a steel plate, three leg nuts 4 are welded on the lower end surface of the steel plate 1, and the straight lines where the three leg nuts 4 are located form a triangular structure, and each leg 2 described The upper end is provided with thread, and each leg 2 is threadedly connected with the corresponding leg nut 4 . That is to say, in this embodiment, three supporting legs 2 are provided in total, and the three supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com