Accurate Matching Method of Automotive Fuses and Connecting Wires

A technology for connecting wires and precise matching, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc. Matching and other issues to achieve the effect of improving development efficiency, reasonable matching, and improved parameter matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

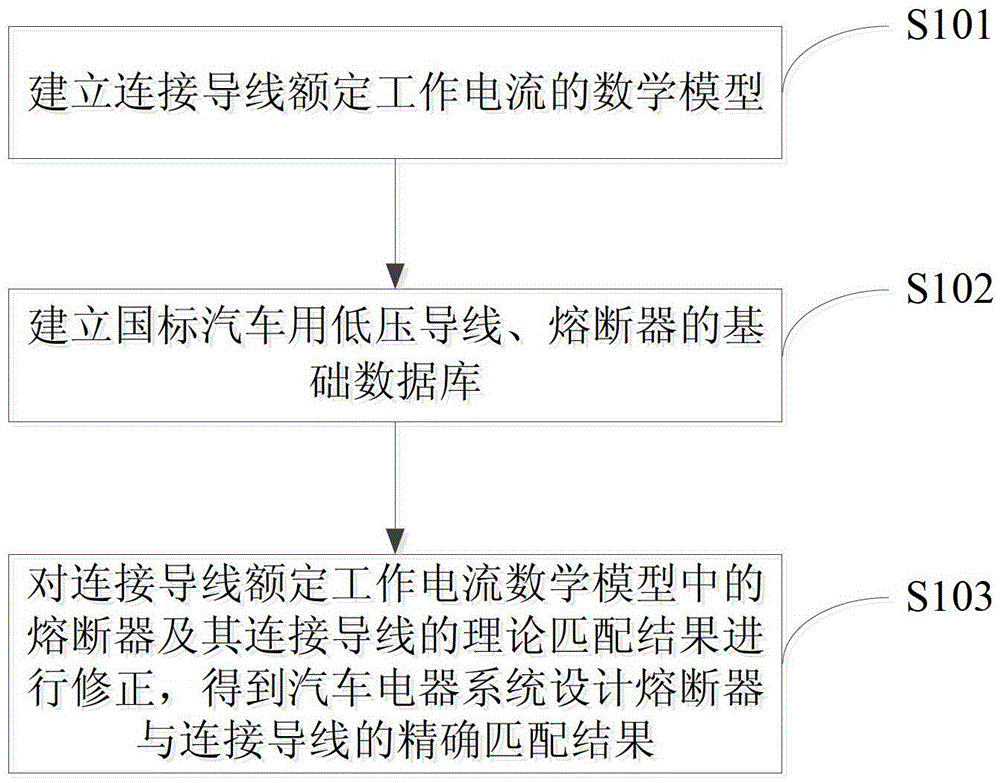

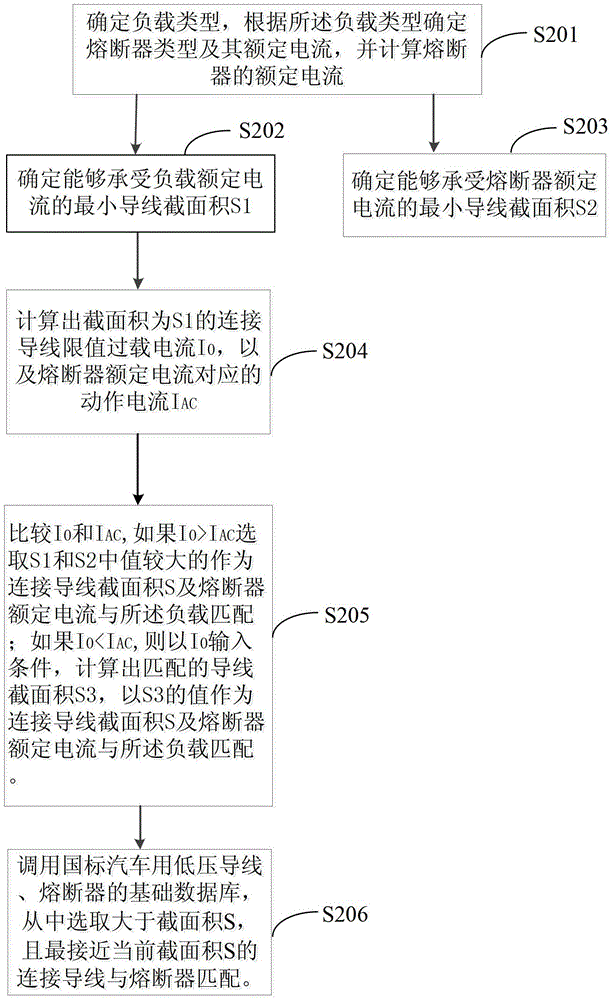

[0013] Such as figure 1 As shown, the precise matching method of automotive fuses and connecting wires includes the following steps:

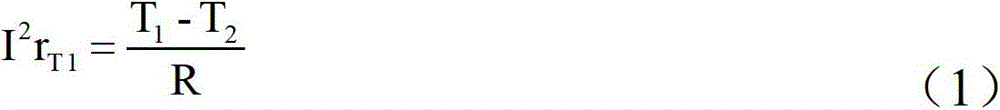

[0014] Step S101 , according to the heating and heat transfer mechanism of the automobile fuse and its connecting wires during operation, establish a mathematical model of the rated operating current of the connecting wires and a transient mathematical model of the rated overload current limit of the connecting wires. Establish the first mathematical model of the rated operating current of the connecting wire according to the heating and heat transfer of the connecting wire and the temperature between the material of the connecting wire, the cross-sectional area, the material of the insulating layer, the outer diameter of the insulating layer and the ambient temperature, and the established first mathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com