Color wheel, light source, projector and manufacturing method of color wheel

A production method and projector technology, applied in the field of color wheels, can solve the problems of low efficiency of dispensing operation and difficulty in controlling the amount of dispensing, and achieve the effects of convenient dispensing, improved efficiency, and simple dispensing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

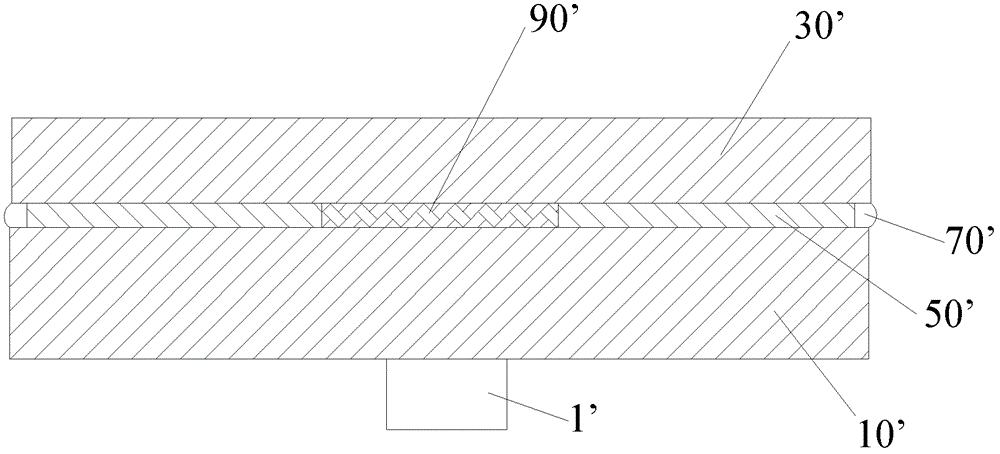

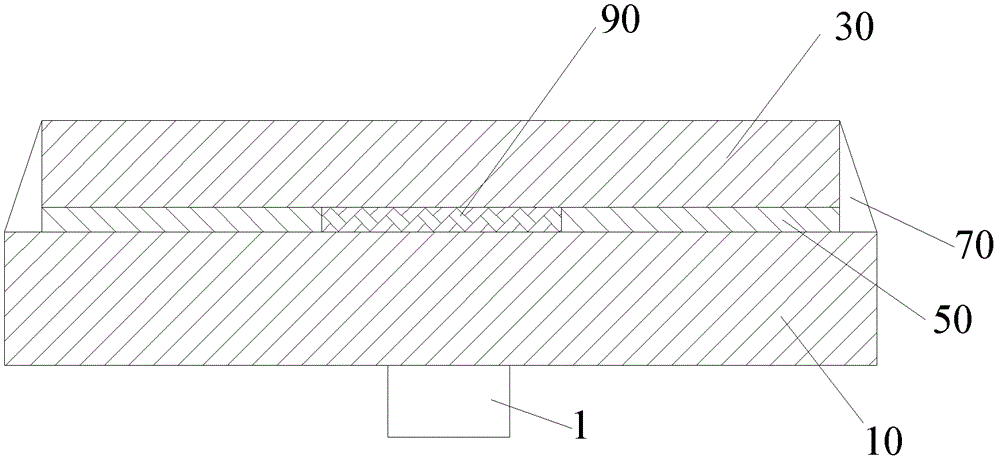

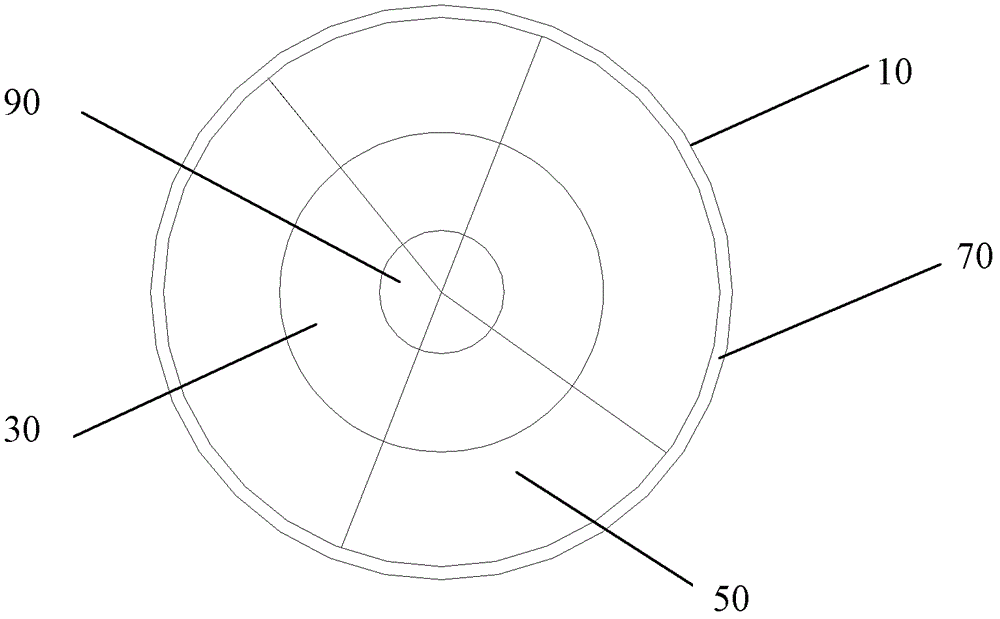

[0025] figure 2 A schematic diagram showing Embodiment 1 of the color wheel according to the present invention, image 3 show figure 2 A schematic top perspective view of the color wheel. See in conjunction with 2 and image 3 , it can be seen from the figure that the color wheel in Embodiment 1 is a disk-shaped color wheel, and the color wheel includes: a substrate 10 , a light-transmitting layer 30 and a wavelength conversion layer 50 stacked in sequence. The color wheel also includes a motor 1 connected to the bottom of the substrate 10 , and the color wheel can be driven to rotate by the motor 1 .

[0026] The wavelength conversion layer 50 includes a wavelength conversion material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com