Externally arranged steam cooler system in heat regenerative system of power plant and heat regenerative system

A technology of steam cooler and heat recovery system, which is applied in the directions of steam generation, feed water heater, preheating, etc. It can solve the problems that the existing technology has not been widely promoted, has high requirements for operation safety, and affects the return on investment, etc., and achieves The effect of increasing the return on investment, improving the safety of operation, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

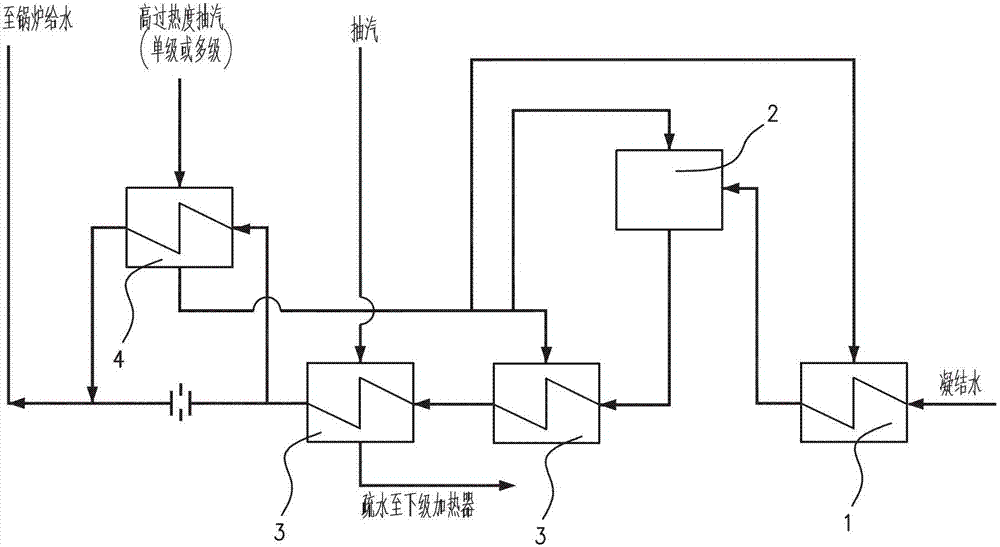

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention. Herein, the same or similar components are marked with the same reference numerals.

[0024] In the present invention, the term "external steam cooler" refers to the heat exchange surface of a heater using steam with a high degree of superheat, which can be divided into a superheated steam cooling section, a saturated steam condensation section and a hydrophobic cooling section. The conventional superheated steam cooling section It can be integrated with other heat exchange sections into the same heater, or part of the superheated steam cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com