Forklift capable of carrying weight-bearing wheel

A heavy-wheel forklift and fork technology is applied in the field of handling track rollers of crawler bulldozers, which can solve the problems of safety accidents, high labor intensity, damage to muscles, bones and flesh, etc., so as to reduce labor intensity, replace work safely, and facilitate easy handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

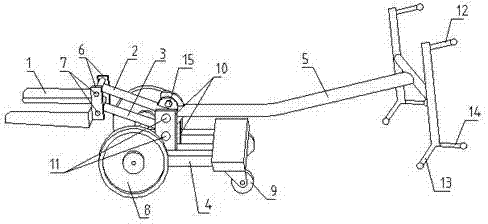

[0009] With reference to the accompanying drawings, it can be seen that the present invention includes a pallet fork 1, parallel rods 2 and 3, a frame assembly 4 and a rod-shaped handle 5, and the support 6 on the pallet fork 1 is connected to the parallel rods 2 and 3 by pin 7. One end is movably connected; the frame assembly 4 is provided with a traveling wheel 8, a universal wheel 9 and a connecting plate 10, and the connecting plate 10 is movably connected with the other ends of the parallel rods 2 and 3 through a pin shaft 11; the rod-shaped hand One end of handle 5 is provided with upper handle 12, lower handle 13 and transition handle 14, and the other end is consolidated with one end of parallel bar 2 by bolt 15.

[0010] The support 6, the parallel rods 2 and 3 and the connecting plate 10 are combined into a parallel mechanism through the movable connection of the pin shafts 7 and 11. The parallel mechanism moves up and down around the upper pin shaft 11 of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com