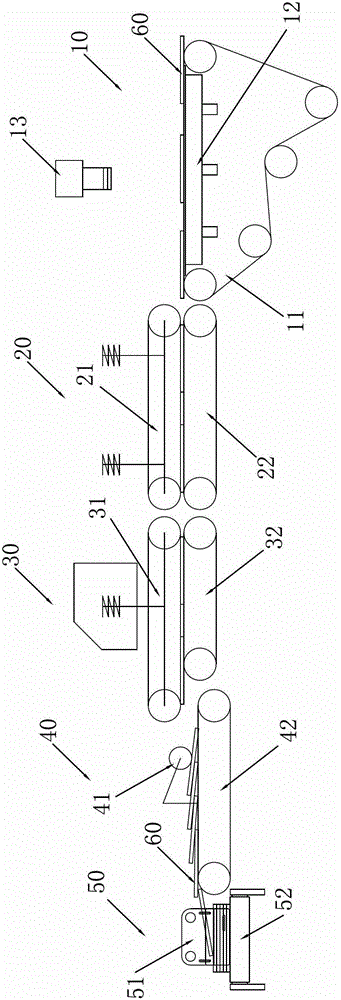

Stacking and collecting mechanism, stacking and collecting method and quality testing machine for small-size prints

A technology for stacking and arranging mechanism and small sheets of printed matter, applied in printing, stacking receiving device, printing device, etc., can solve the problems of large vibration of pneumatic component cylinder, influence of test results, unstable structure, etc., to overcome large vibration , The output is stable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

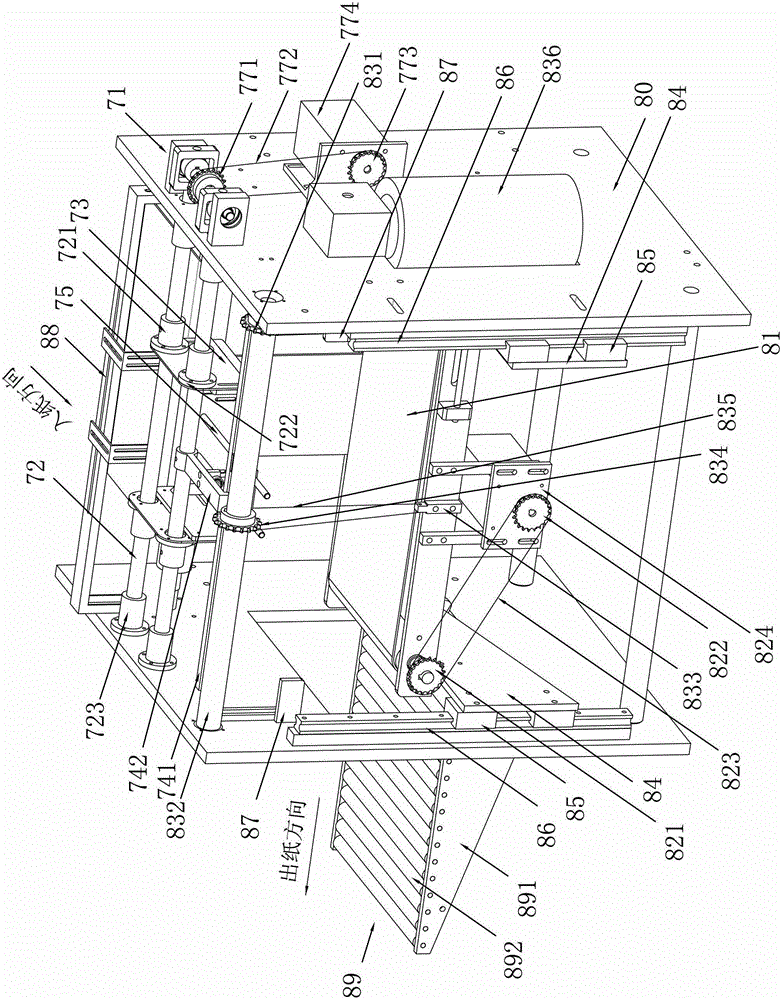

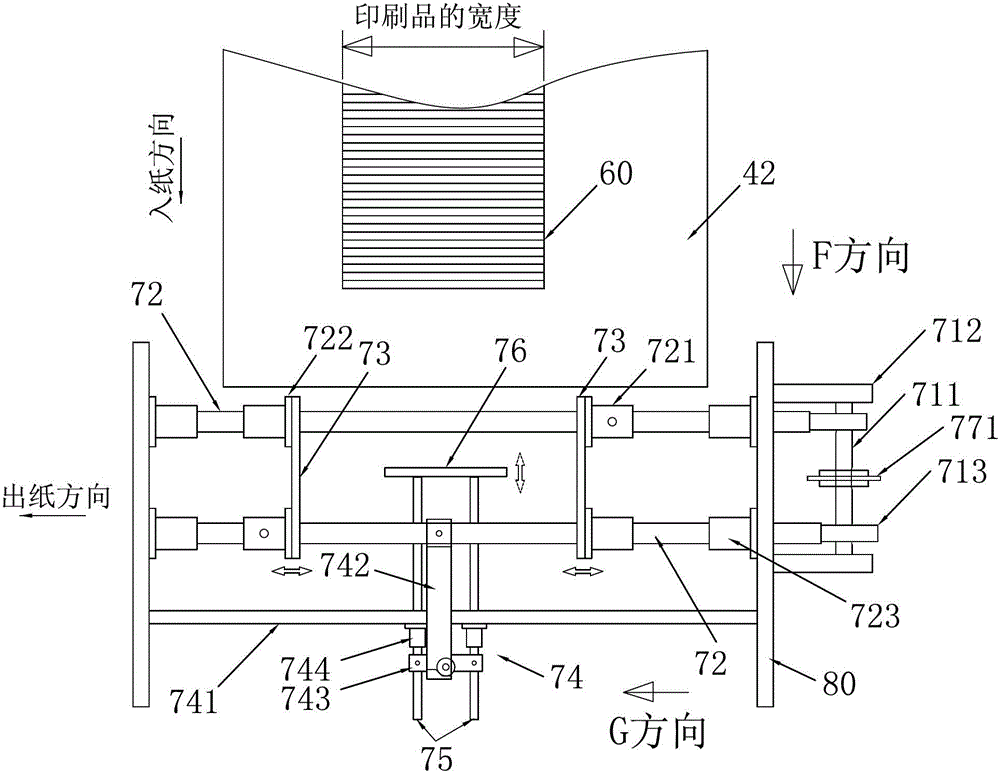

[0029] Such as Figure 2 to Figure 6 As shown, the small-sheet printed matter stacking and collecting mechanism of the present invention includes two main wallboards 80 vertically opposite to each other. The upper parts of the two main wallboards 80 are equipped with a snapping device, and the bottom of the snapping device is provided with Stack output devices where:

[0030] The aligning device includes two supporting beams 72 movably installed between the two main wallboards 80. In practice, the supporting beams 72 can perform axial sliding movement through the linear bearings 723 assembled on the main wallboards 80. , one end of the two supporting beams 72 arranged in parallel passes through a corresponding main wallboard 80 and is connected with the cam mechanism 71, and the cam mechanism 71 is connected with the speed control motor 774 via the speed control transmission mechanism, and the two support beams 72 A pair of side push plates 73 are installed on the top, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com