Front cross member and front bracket beam connecting structure for cars

A technology for connecting structures and front beams, applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of resonance noise in the cab, shaking of the front bracket beam 2 and the front beam 1, poor stability, etc., to eliminate The effect of resonance noise, easy retrofit, and low retrofit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

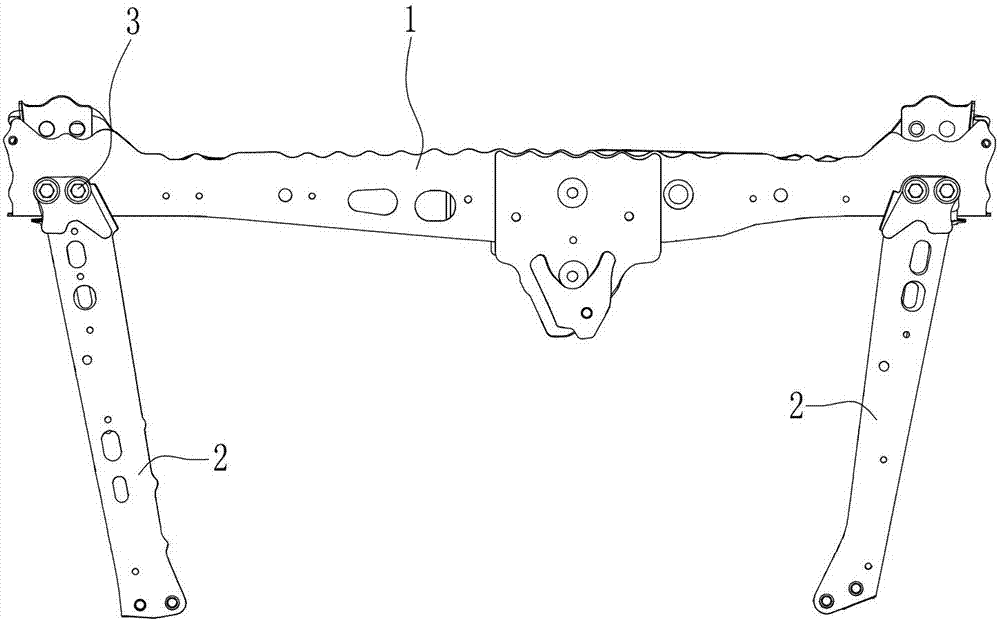

[0014] Such as figure 1 Shown, the present invention is made of front beam 1, front bracket beam 2, reinforcement plate 4 and bolt etc. Wherein, the front beam 1 and the front bracket beam 2 are all prior art, and their structures will not be repeated here. The front bracket beams 2 are arranged at the left and right ends of the front beam 1 , and reinforcing plates 4 are provided at the angles between each front bracket beam 2 and the front beam 1 . The reinforcing plate 4 is triangular and made of 2.8-3.2mm thick hot-rolled steel plate for automobile structure. In this embodiment, the thickness of the reinforcing plate 4 is preferably 3 mm, one side of the reinforcing plate 4 is in the same direction as the length direction of the front beam 1, and the other side of the reinforcing plate 4 is in the same direction as the length direction of the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com