A pouring riser removal machine

A technology for pouring risers and auxiliary guide rails, applied in the field of automation equipment, can solve the problems of high repetitive labor intensity, difficult processing of large parts, low automation level, etc., and achieve the effect of reducing labor intensity, meeting size, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention discloses a sprue riser removal machine with relatively high automation degree, relatively high production efficiency and maximum economic benefit.

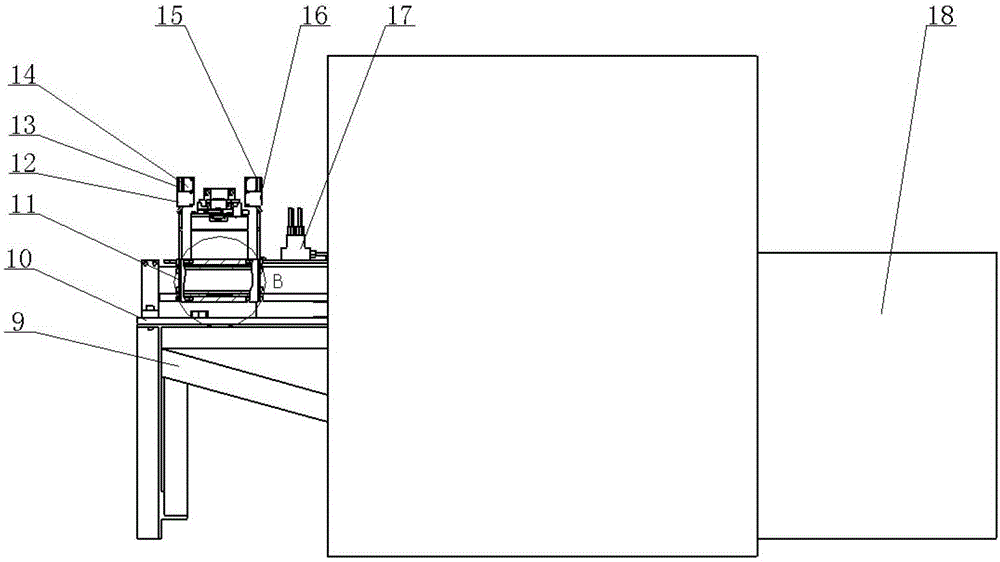

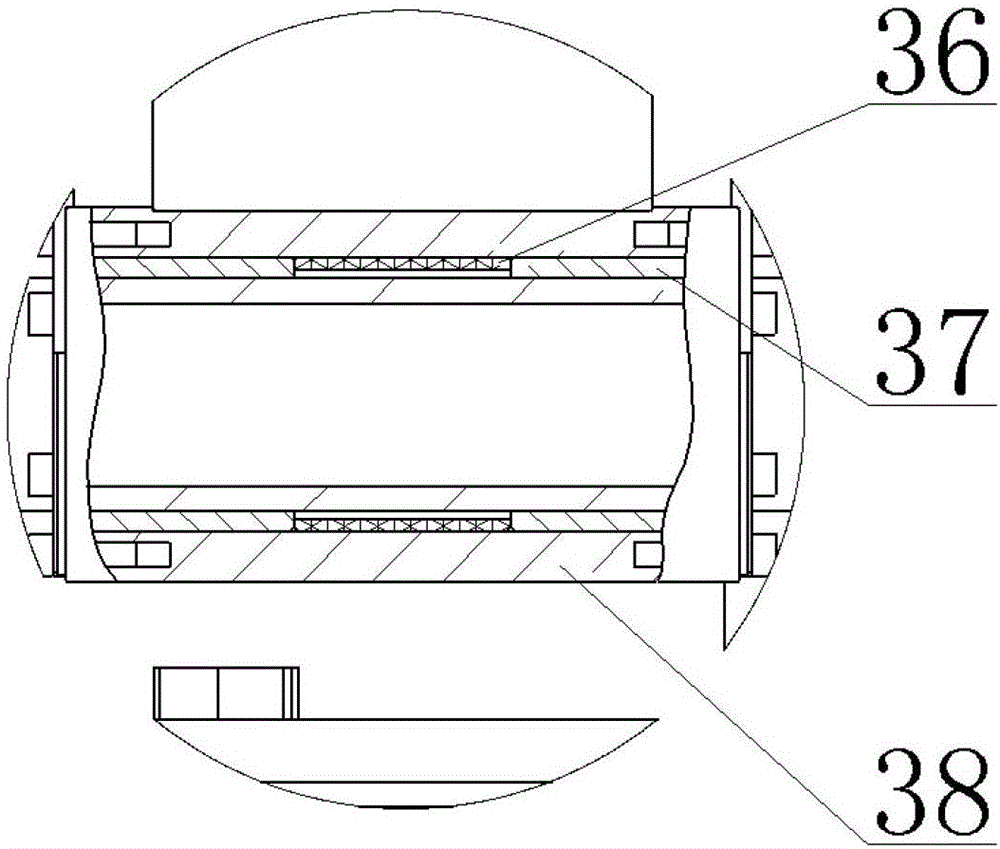

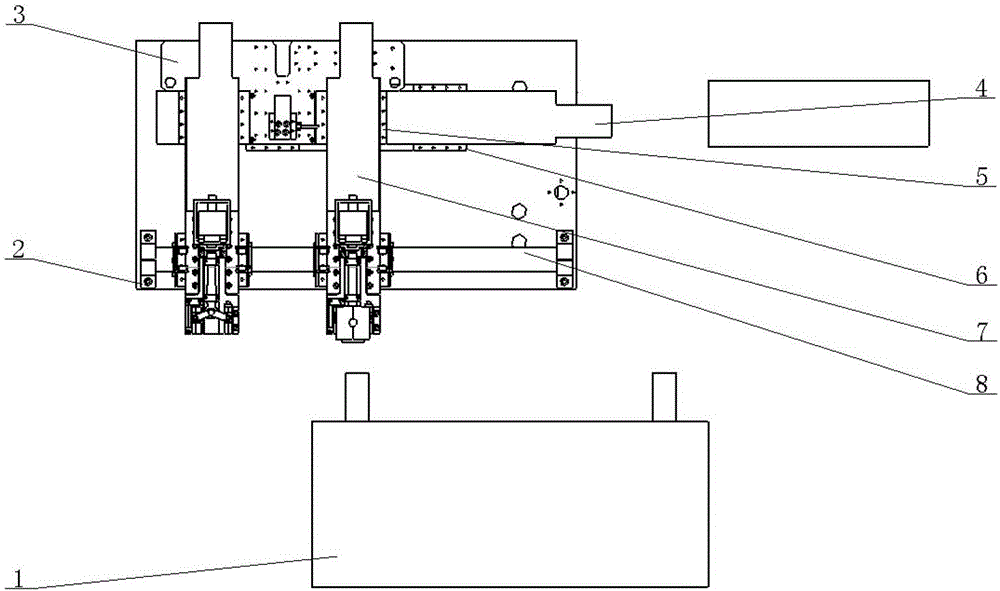

[0035] The pouring riser removal machine includes a bed, a table top, a translation module arranged on the table top, an auxiliary guide rail module arranged on the table top for resisting grinding force, a control cabinet and a grinder, and the translation module is provided with There are a plurality of stations, and each station is equipped with a feed unit and a clamp unit, and the feed unit is equipped with sensors for dimension measurement before and after removal of the gate riser.

[0036] Further, the clamp unit includes a base, a workpiece positioning frame arranged on the base, a shaft pin, a first clamp driving rod, a second clamp driving rod, a clamp connecting the first clamp driving rod and the second clamp driving rod The drive rod connects the pin, the cylinder that controls the movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com