High temperature test chamber

A high-temperature test chamber and heat-resistant technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of slow temperature rise, difficulty in reaching the temperature, increasing the volume of test equipment, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

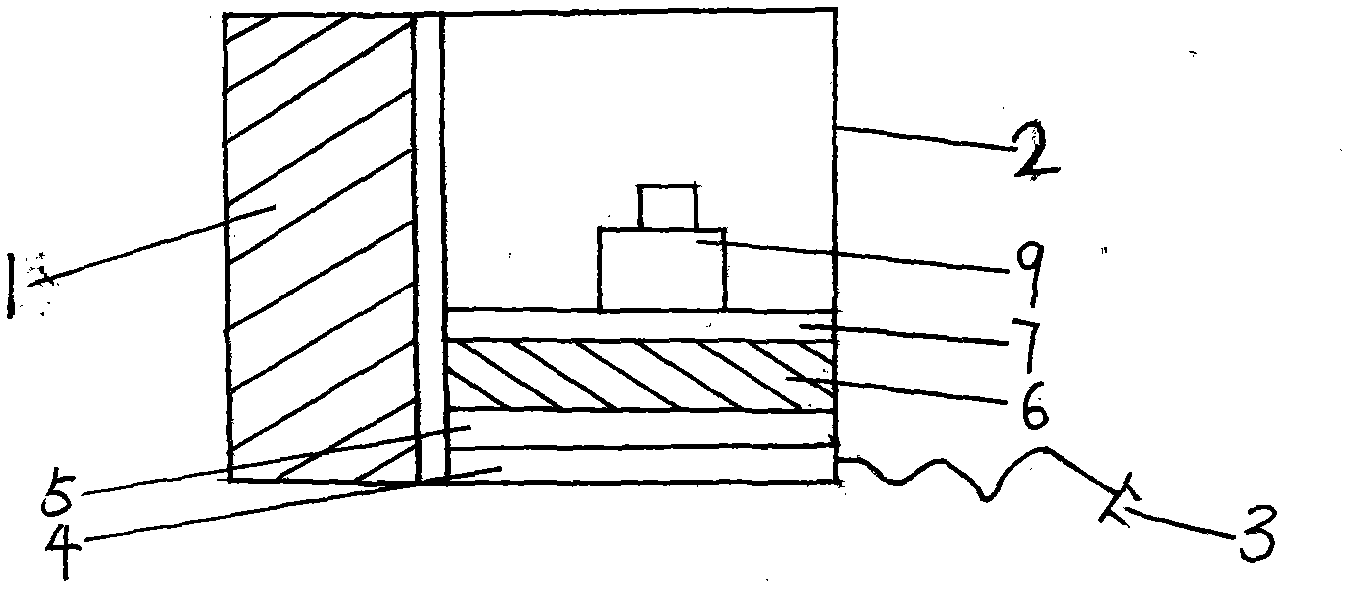

[0013] exist figure 1 Among them, the door (1) is next to the test box shell (2), and the power plug (3) is located below. There is a heat-resistant protective net (7) inside the test box shell (2), and the heat-resistant protective net (7) The test article (9) is placed above, the electrode (6) is below the heat-resistant protective net (7), the fan (5) is below the electrode (6), and the circuit board (4) is below the fan (5).

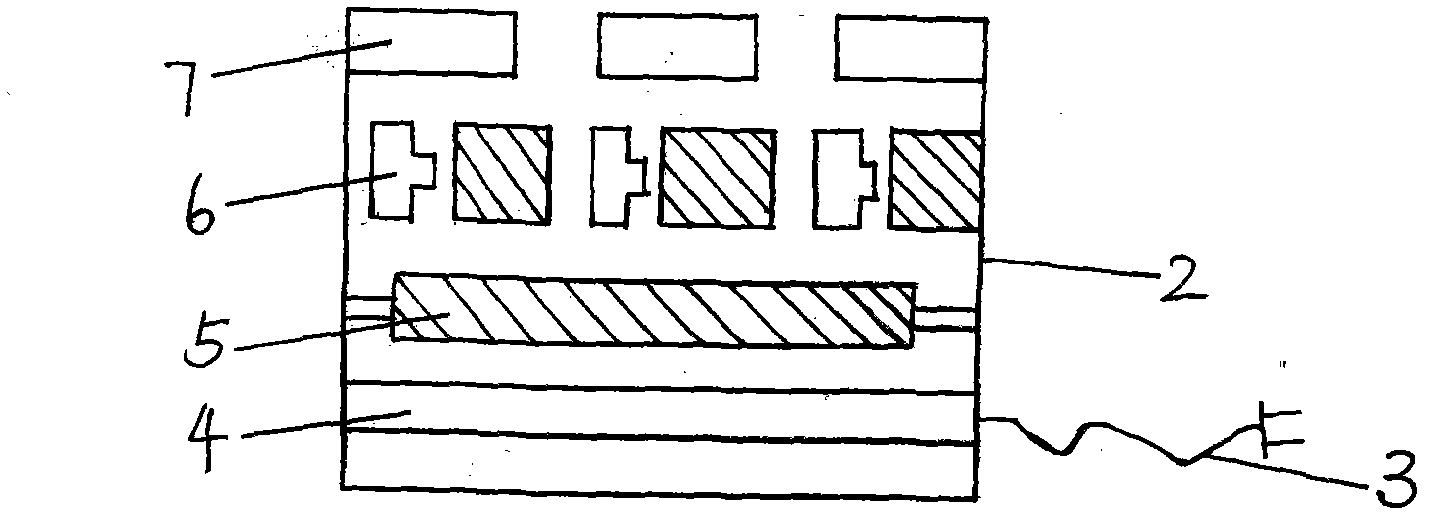

[0014] exist figure 2 Among them, the top of the test box shell (2) is a heat-resistant protective net (7), the electrode (6) is located below the heat-resistant protective net (7), the fan (5) is located below the electrode (6), and the fan (5) Below is the circuit board (4) and the power plug (3). When the power is turned on, an arc is generated on the electrode (6), and the arc generates high temperature. At the same time, the fan (5) below the electrode (6) also starts to rotate, and the fan ( 5) Blow the high temperature generated by the arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com