Simple workpiece clamping device for feeding mechanism

A feeding mechanism and workpiece clamping technology, applied in metal processing, etc., can solve the problems of unreasonable structural design of the workpiece clamping part, low work efficiency of workers, and high production cost of the enterprise, so as to achieve simple maintenance work, improve work efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

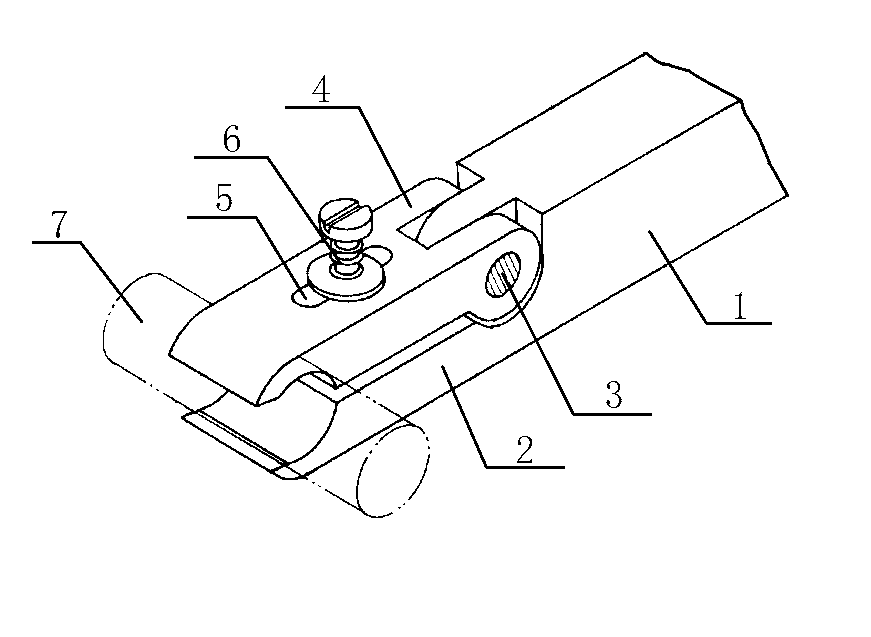

[0009] Such as figure 1 As shown, the present invention provides a simple workpiece clamping tool for a feeding mechanism, including a pull arm 1, a fixed clip 2 and an elastic clip 4, the pull arm 1 and the fixed clip 2 are integrally formed; the elastic clip 4 passes through the hinge shaft 3 It is hinged with the pull arm 1; the fixed clip 2 and the elastic clip 4 form a collet, and the inner wall of the collet is adapted to the outer wall of the workpiece 7; the elastic clip 4 is provided with a notch 5, and the notch 5 is provided with a fixed clip The block 2 is connected to the spring 6 of the elastic clamp block 4.

[0010] In this embodiment, the arrangement of the collet can provide conditions for clamping the workpiece 7, and the arrangement of the fixed clamp block 2 and the elastic clamp block 4 realizes the opening and closing of the collet.

[0011] In addition, the arrangement of the notch 5 and the spring 6 mainly considers the adjustment of the grip force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com