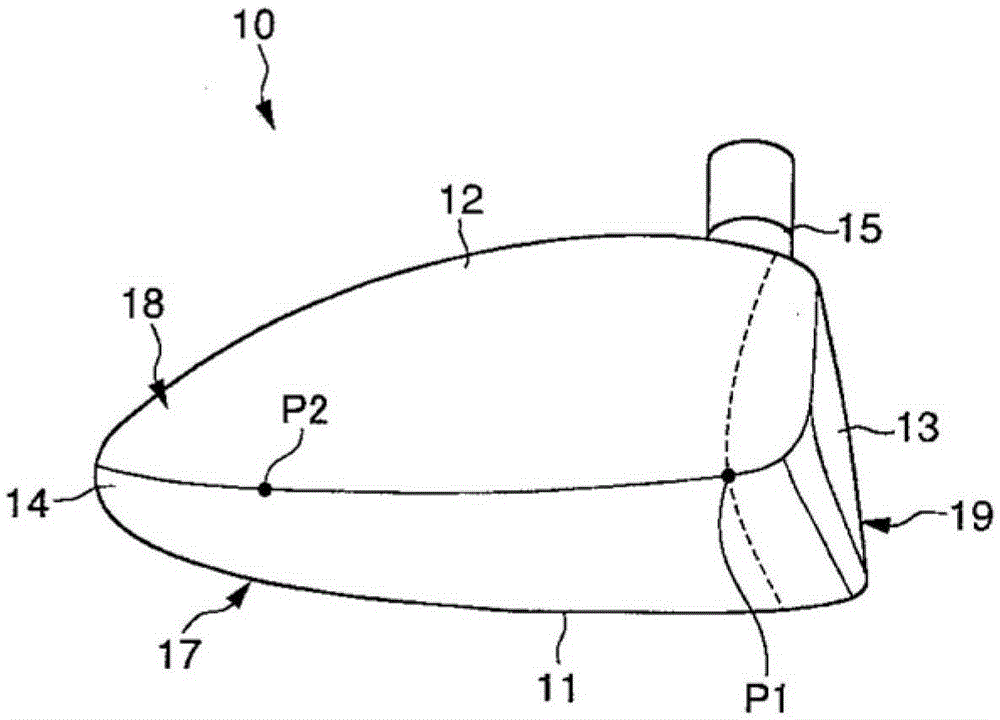

golf club head

A golf club head and club head technology, applied in golf balls, golf clubs, rackets, etc., can solve the problems of strength, difficulty in obtaining, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] [Cue Specification]

[0030] Appearance order No. 1 (No. 1 wood, lie angle: 64 degrees)

[0031] The area of the top forming part of the head is 13150mm 2

[0032] The area of the sole forming part of the head is 14277mm 2

[0033] The area of the top surface forming part / the area of the bottom surface forming part 92%

[0034] The top plate thickness of the head is 0.6mm (78% of the top surface of the head, the remaining 22% is 0.75mm)

[0035] The joint position of the head top surface forming member and the head bottom surface forming member ( image 3 The joint position 30A~30C is within the range of 1 / 4~1 / 2)

[0036] The thickness of the bottom forming part of the head is 0.75mm

[0037] 11 degrees of loft

[0038] Head weight 179.5g

[0039] Head volume 460cc

[0040] Shaft for 2010inpresXClassic 1 wood (softness R)

[0041] For grip 2010inpresXClassic 1 driver

[0042] Club length 46.25 inches

[0043] Total club weight 275g

[0044] Balance C3

[0045] The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com