Optical glass for precision molding

A kind of optical glass and glass technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of high volatilization of glass components, unsuitable optical glass, adhesion of mold surface, etc., and achieve low dispersion, low element volatilization and diffusion, and high refraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

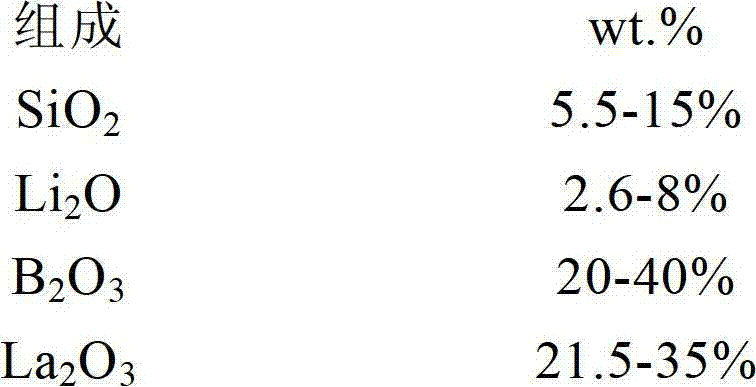

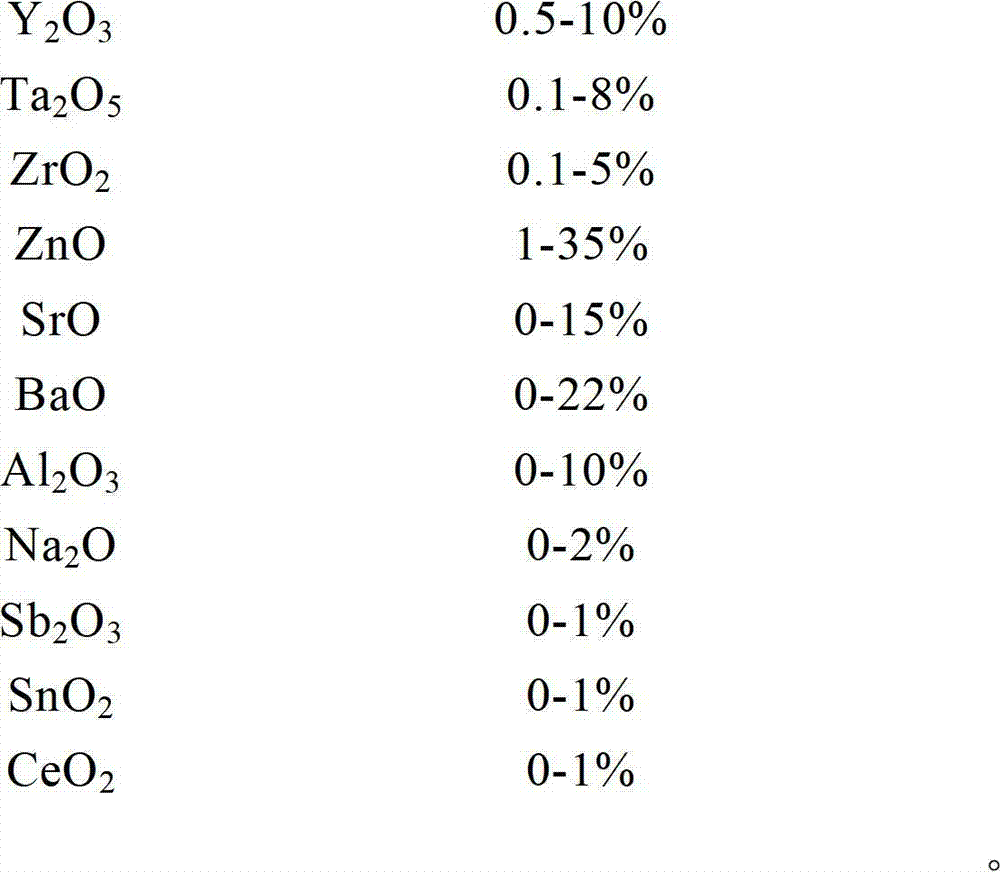

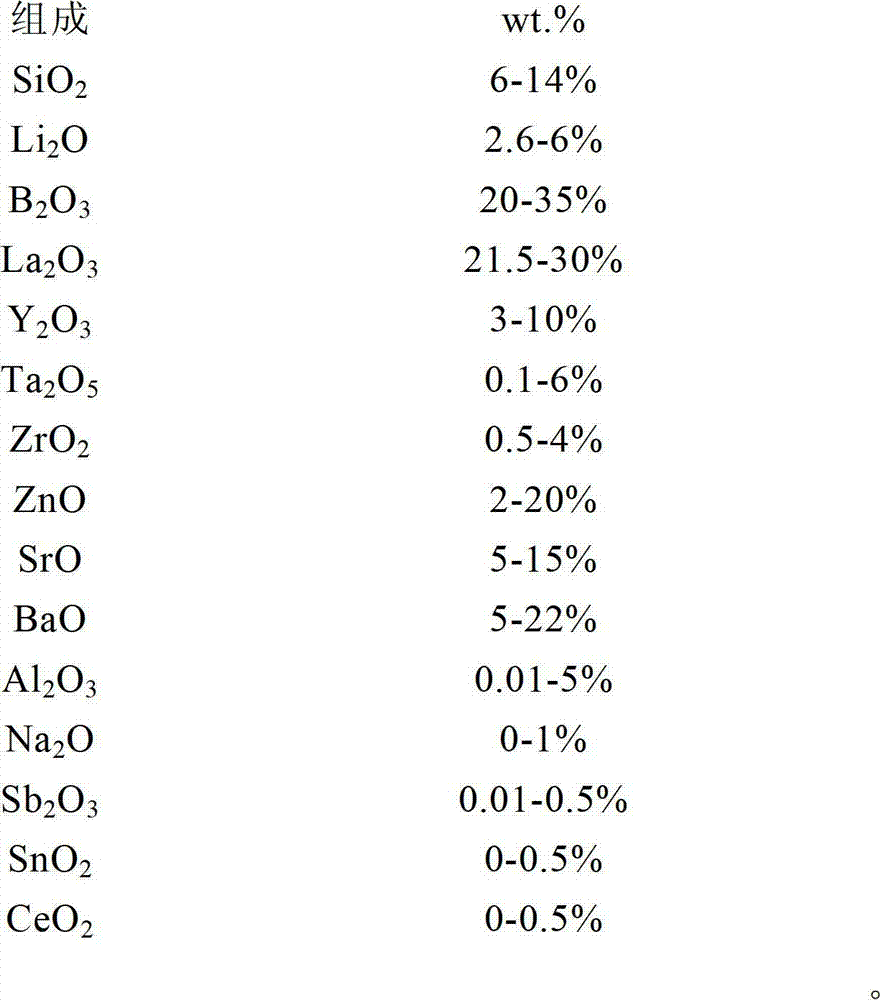

[0061] Table 1 is an example of an embodiment within a preferred composition range, and the glass described in the example is prepared according to the following steps:

[0062] The raw materials used are commercially available conventional oxides, hydroxides, carbonates and nitrates, etc., all purchased from Sinopharm Chemical Reagent Co., Ltd. (Suzhou), chemical grade. After weighing and mixing according to the weight composition listed in the table, the mixture was put into a 500ml platinum crucible. Melting, clarifying and homogenizing in electric furnace at 1100-1400°C and cooling down. It can be obtained by casting molten glass into a metal mold preheated at 400°C, and then placing the glass and metal mold in an annealing furnace for annealing and cooling.

[0063]Table 1 shows the composition, refractive index, Abbe number and transition temperature of Examples 1-6, wherein the content is expressed in wt% based on oxide.

[0064] The glass sample was made into a 20×20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com